Secondary positioning method and structure for 3D printing feeding

A 3D printing and secondary positioning technology, applied in processing and manufacturing, manufacturing auxiliary devices, processing data acquisition/processing, etc., can solve the problems of complex feeding printing process, waste of paraffin raw materials, and reducing printing efficiency, and achieve accurate feeding. The effect of high degree of utilization, improved utilization, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

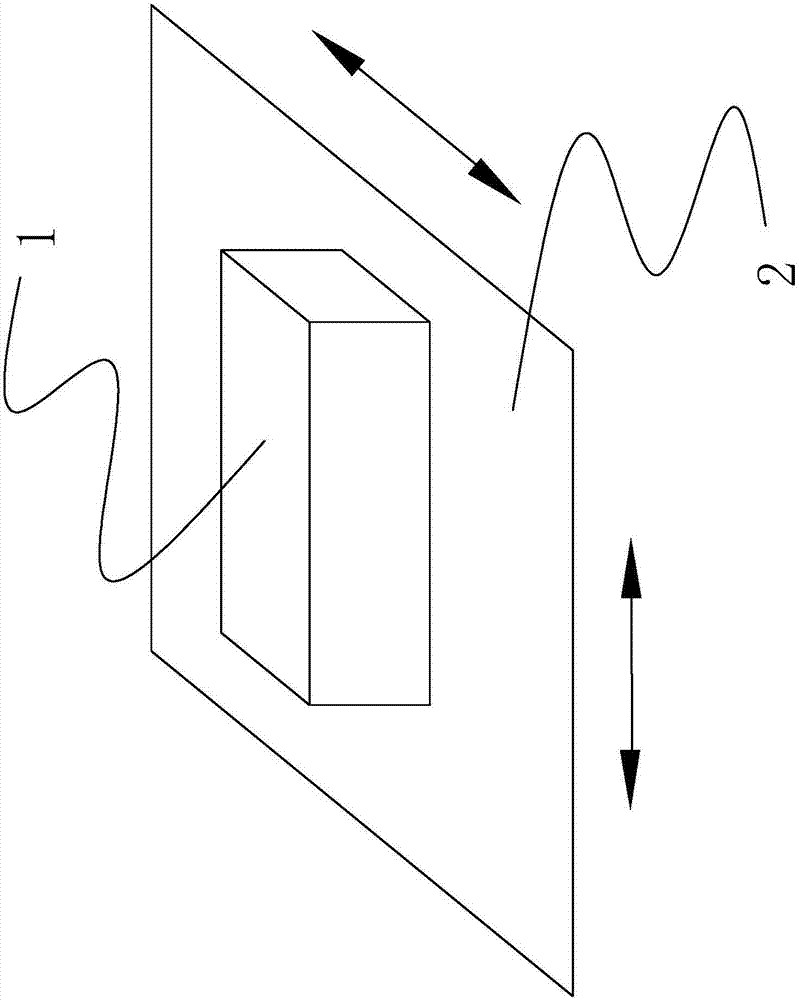

Image

Examples

Embodiment 1

[0032] A secondary positioning method for 3D printing replenishment, which includes the following steps:

[0033] 1) Identify nozzle clogging according to the printed output of the entire nozzle head 1, determine that the B15 and B16 nozzles are completely blocked and not working, and the nozzles are judged to have no discharge, and input the coordinate position into the control system to obtain a positioning pattern layer;

[0034] 2) According to the 8pass printing mechanism, it is determined to use B13 / 14, B23 / 24, B33 / 34, B43 / 44, B53 / 54, B63 / 64, B73 / 74, B83 / 84 nozzles for feeding, and the coordinate position Input it into the control system to get the pattern layer for secondary positioning and feeding;

[0035] 3) The product model is sliced and layered, and the secondary positioning and replenishing pattern layer obtained in step 2) is inserted into each layer through the control system, and then the overlapping part with the layer is respectively reserved to form a pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com