Electronic weighing system

A weighing system and electronic technology, applied in the direction of material weighing, weighing, weighing equipment using elastically deformable parts, etc., can solve the problems of low accuracy and sensitivity, and the weighing system cannot reflect quality changes, etc. Achieve the effect of simplifying the circuit, ensuring timeliness and sensitivity, and high acquisition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

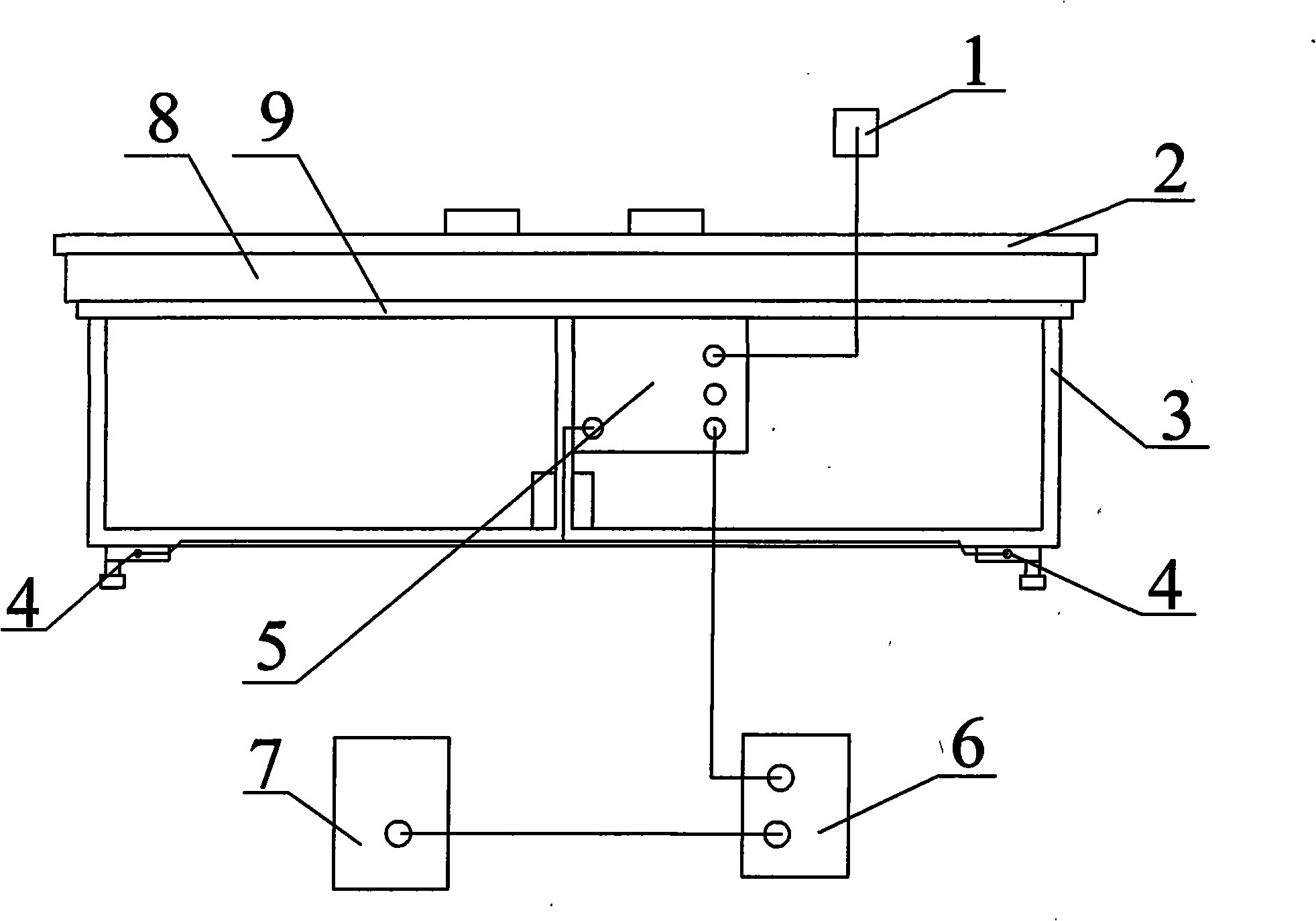

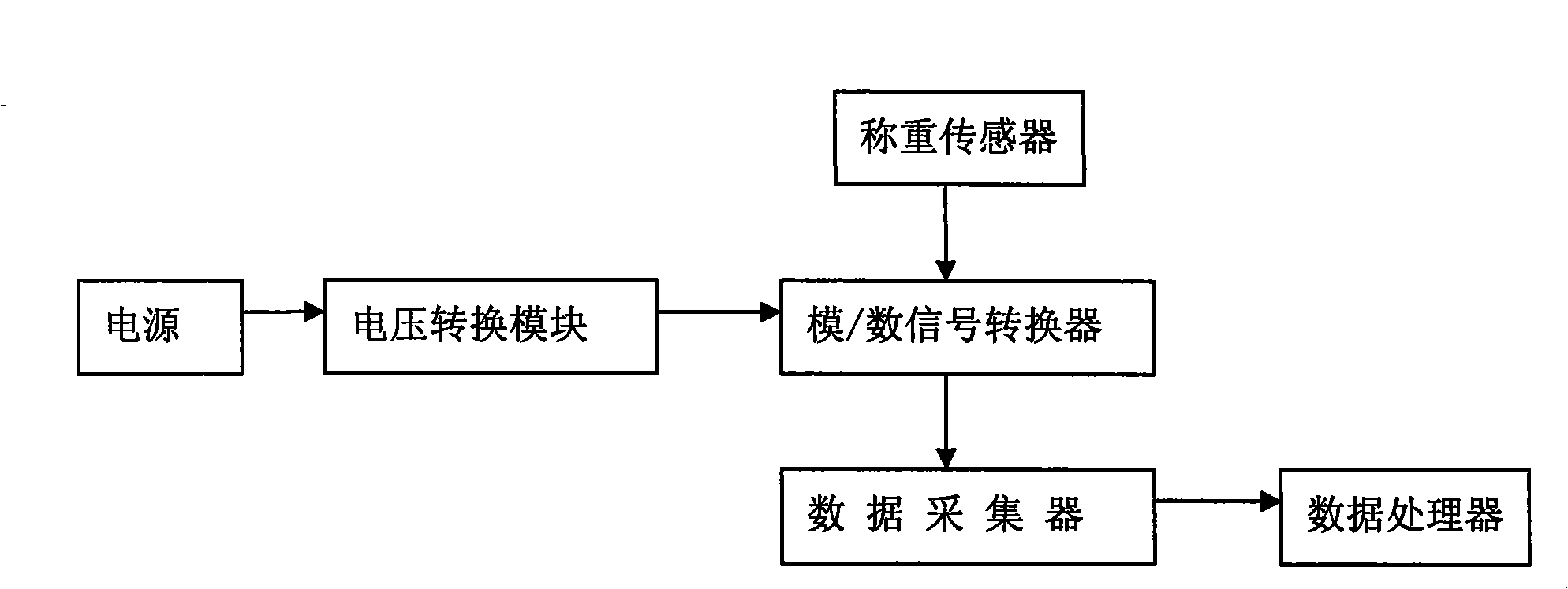

[0018] The schematic diagram of the electronic weighing system of the present invention is as shown in Figure 1 and Figure 2, comprises metal support 3, is fixed with support plate 9 on the support plate 3, is placed with the heat shield 8 that prevents heat radiation on the support plate 9, heat shield 8 is placed with a loading tray 2, and load cells 4 are respectively installed on the 4 legs of the metal bracket, and each load cell is connected with an analog / digital signal converter respectively, and the analog / digital signal converter is respectively It is connected with the voltage conversion module and the data collector 6, the data collector 6 is connected with the data processor 7, and the voltage conversion module is connected with the power supply 1. The load cell is a resistance strain sensor, and the weighing quality range is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com