Automatic unloading device for recrement

An automatic unloading and gangue technology, which is applied in the direction of loading/unloading, transportation and packaging, transporting passenger cars, etc., can solve the problems of affecting the timely transfer of materials, adverse environmental effects, and increased production costs, so as to simplify the structure, reduce the occupied area, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

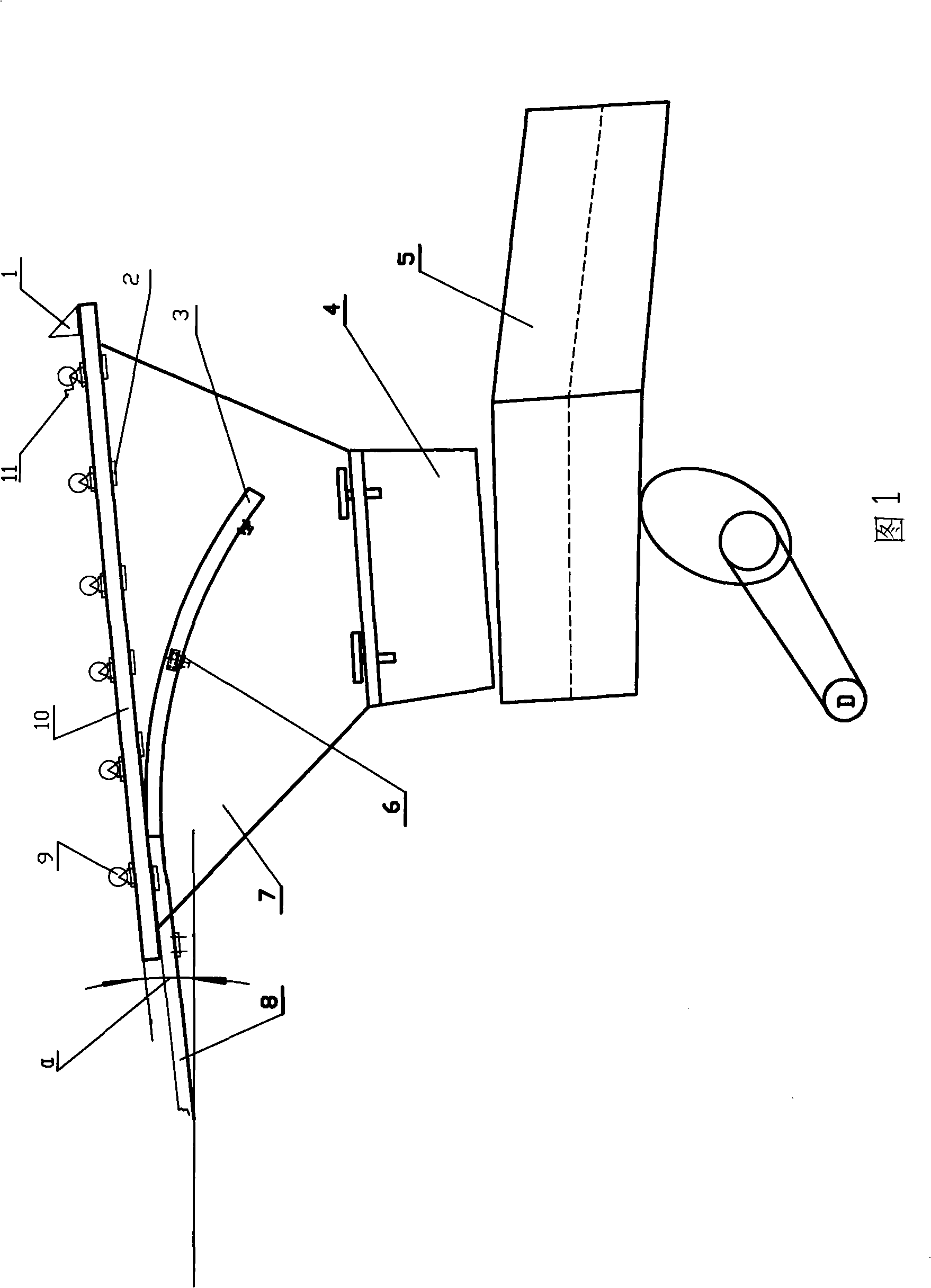

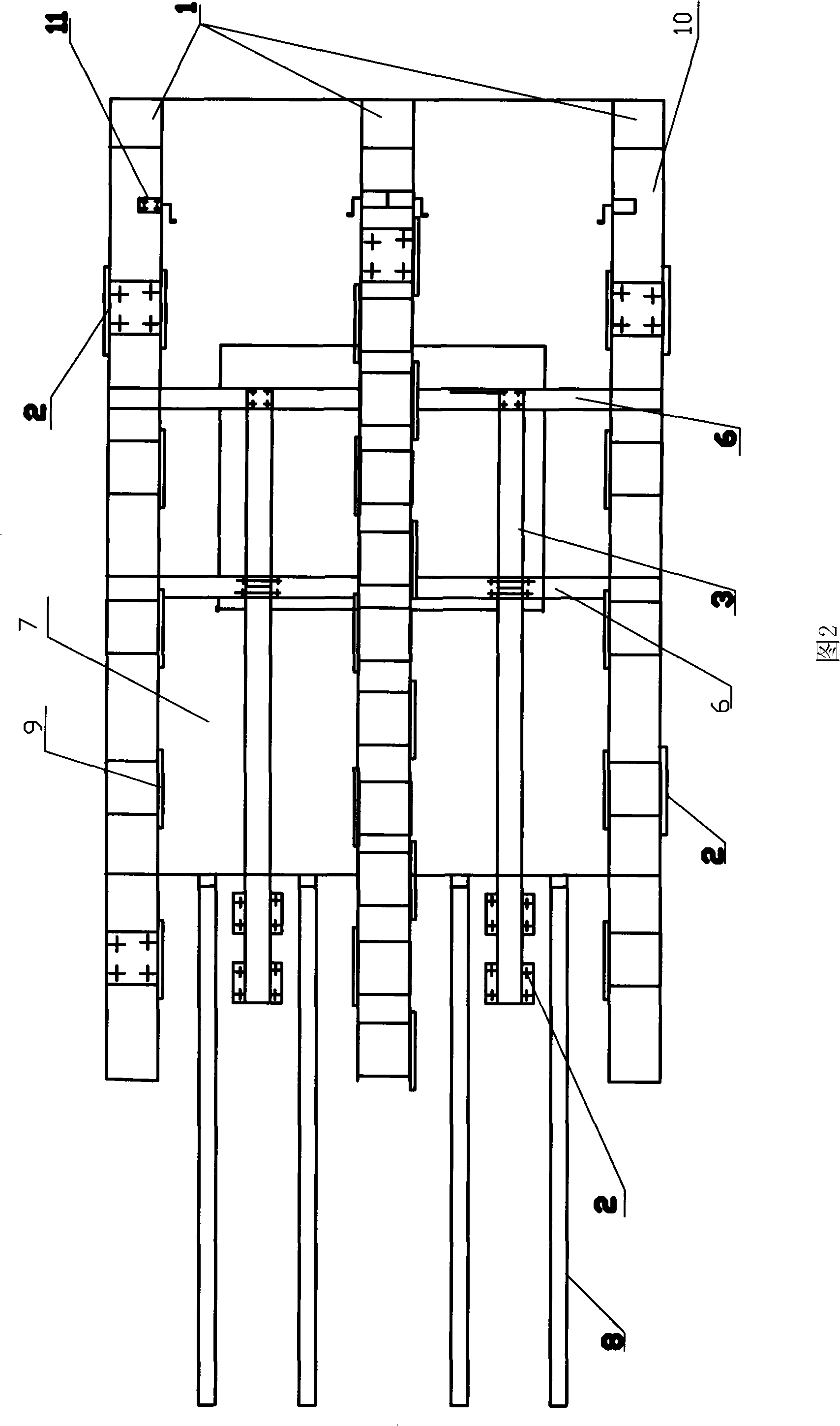

[0026] The first embodiment is an automatic gangue unloading device for a gangue transfer line with a gangue transfer capacity of 500 tons per shift. Its supporting power is 2×180kw for traction transfer vehicles and 11.5kw for feeders, and the overall size of the equipment is 780×430 ×600cm, see figure 1 and figure 2 .

[0027] In this example, on the terminal side of the double-track track 8, a gangue bin 7 fixedly connected to the support foundation is provided as the cavity channel in the inventive solution. The gangue bin is a rectangular bin mouth, with a large upper part and a smaller guiding cavity. The side of the upper mouth of the gangue bin near the track is connected with the terminal of the track.

[0028] The upper opening of the waste rock warehouse is respectively located on the two tracks of the double track, and the side walls on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com