Open cycle internal combustion engine

An open-cycle, internal-combustion engine technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., which can solve the problems of restricted use, high cost, acquisition cost, and low supply of reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

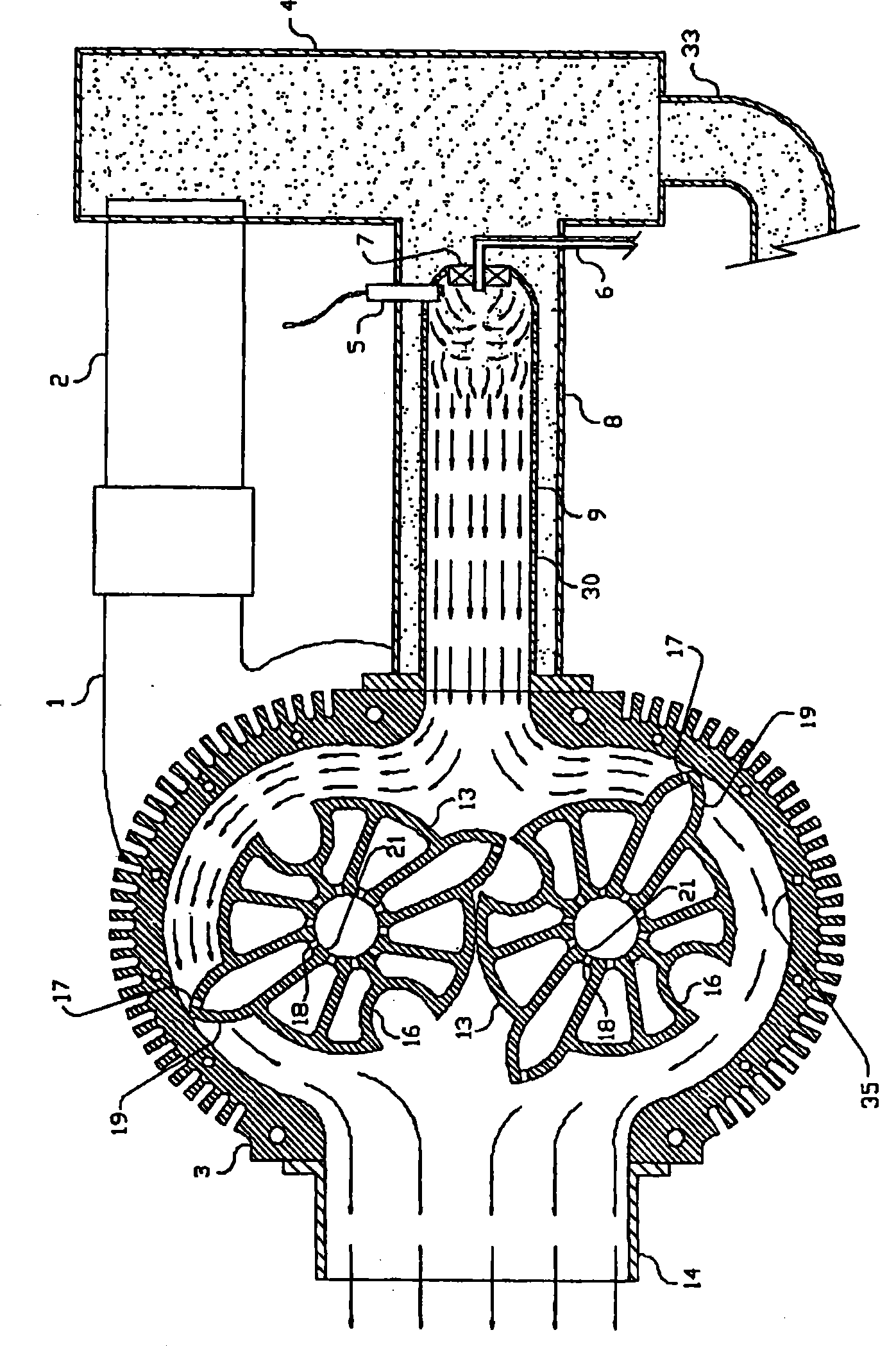

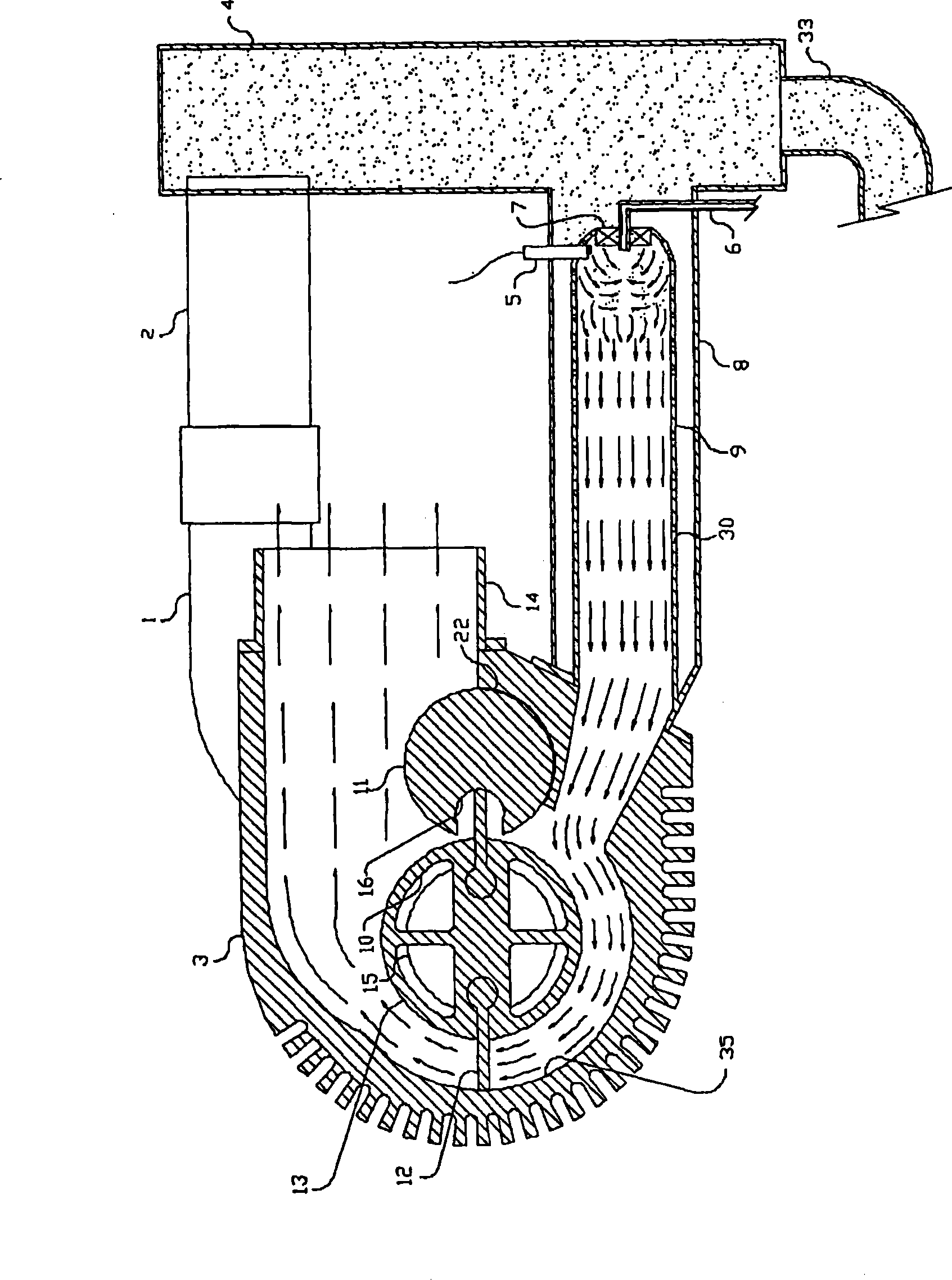

[0025] figure 1 and 1A A cross-sectional view of a preferred embodiment of the open cycle internal combustion engine of the present invention is shown. figure 1 The section of is obtained by cutting the line through the midpoint of the rotor 13, the combustor lining 9 and the high pressure 4. exist Figure 1A The rotor shaft piston 23 shown in is not depicted in this view. Figure 1A The section is taken longitudinally through the center of the hollow rotor shaft.

[0026] working:

[0027] The centrifugal compressor 1 driven by a drive gear 29 on one of the rotor shafts 21 forces compressed air through the compressed air duct 2 and into the high pressure chamber 4 . High pressure chamber 4 delivers compressed air to combustor shroud 8 , which in turn conducts compressed air to swirler nozzle 7 and combustor liner 9 . Fuel is introduced into the combustion zone by supplying fuel metering nozzles 6 fed by fuel metering pumps of conventional design, not shown in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com