Variable-speed pumped storage generator motor with electric axial flow-centrifugal radial axial pressurization end ventilation system

A generator motor, radial ventilation technology, applied in the direction of hydropower, electric components, magnetic circuit rotating parts, etc., can solve the problems of unreasonable ventilation and cooling design, high temperature of stator end windings, to improve flow and pressure, improve Surface heat dissipation coefficient, the effect of accelerating the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

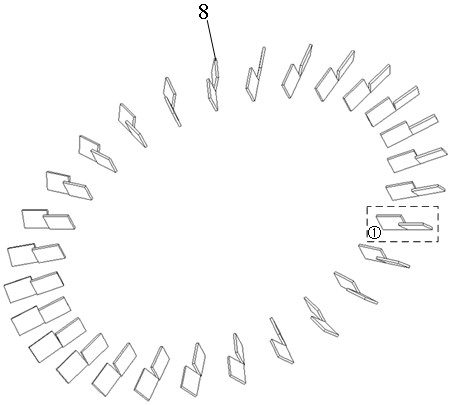

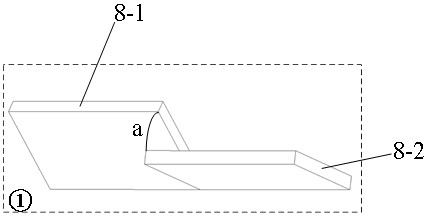

[0025] Embodiment 1: Combining figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 Illustrating this embodiment, it includes a cooler 1, a stator support 2, a stator positioning rib 3, a stator iron core 4, a stator iron core radial ventilation groove 5, a rotor iron core 6, a rotor iron core radial ventilation groove 7, an electric axial flow-centrifugal Fan 8, centrifugal fan 9, rotor outer fixing plate 10, wind deflector 11, rotating shaft 12, stator pressure ring 13, stator pressure finger 14, stator end winding 15, rotor outer guard ring 16, rotor end winding 17, Inclined wind deflector 18, rotor pressure finger 19, rotor inner guard ring 20, casing 21, rotor single-stage axial fan 22, multi-stage sub-pressurized ventilation channel steel 23, wind guide teeth 24, rotor outer The radial vent 25 of the guard ring, the booster axial fan 26 and the ventilation hole 27, the stator core 4 is provided with a stator core radial ventil...

specific Embodiment approach 2

[0028] Specific implementation mode 2: Combining Figure 9 Describing this embodiment, the difference between this embodiment and Embodiment 1 is that the rotor outer shroud 16 is newly provided with a fourth-stage radial vent 25-4 and a fifth-stage radial vent 25-5 in the axial direction. , the contact area between the rotor outer shroud 16 and the cooling gas is increased, and the maximum temperature of the rotor outer shroud 16 is further reduced. Other components and connection relationships are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation three: combination Figure 10 Describing this embodiment, the difference between this embodiment and the first embodiment is that the rotors on both sides of the rotating shaft 12 are adjusted to the single-stage axial flow fan 22 as a supercharging shaft composed of a static fan blade 26-1 and a moving fan blade 26-2. The flow fan 26 can ensure that the cooling gas enters the generator motor regularly through the static fan 26-1, which further reduces the ventilation loss of the cooling gas. Other components and connection relationships are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com