Detection device for combination property of hydraulic ABS pressure regulator assembly

A pressure regulator, comprehensive performance technology, applied in the direction of measuring device, force/torque/work measuring instrument, machine/structural component testing, etc., can solve problems - performance testing of solenoid valve components, fatigue of test operators, Unable to qualitatively evaluate and other problems, to achieve the effect of strong repeatability, high degree of automation, and small pipeline damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below is that the present invention is further described in conjunction with accompanying drawing:

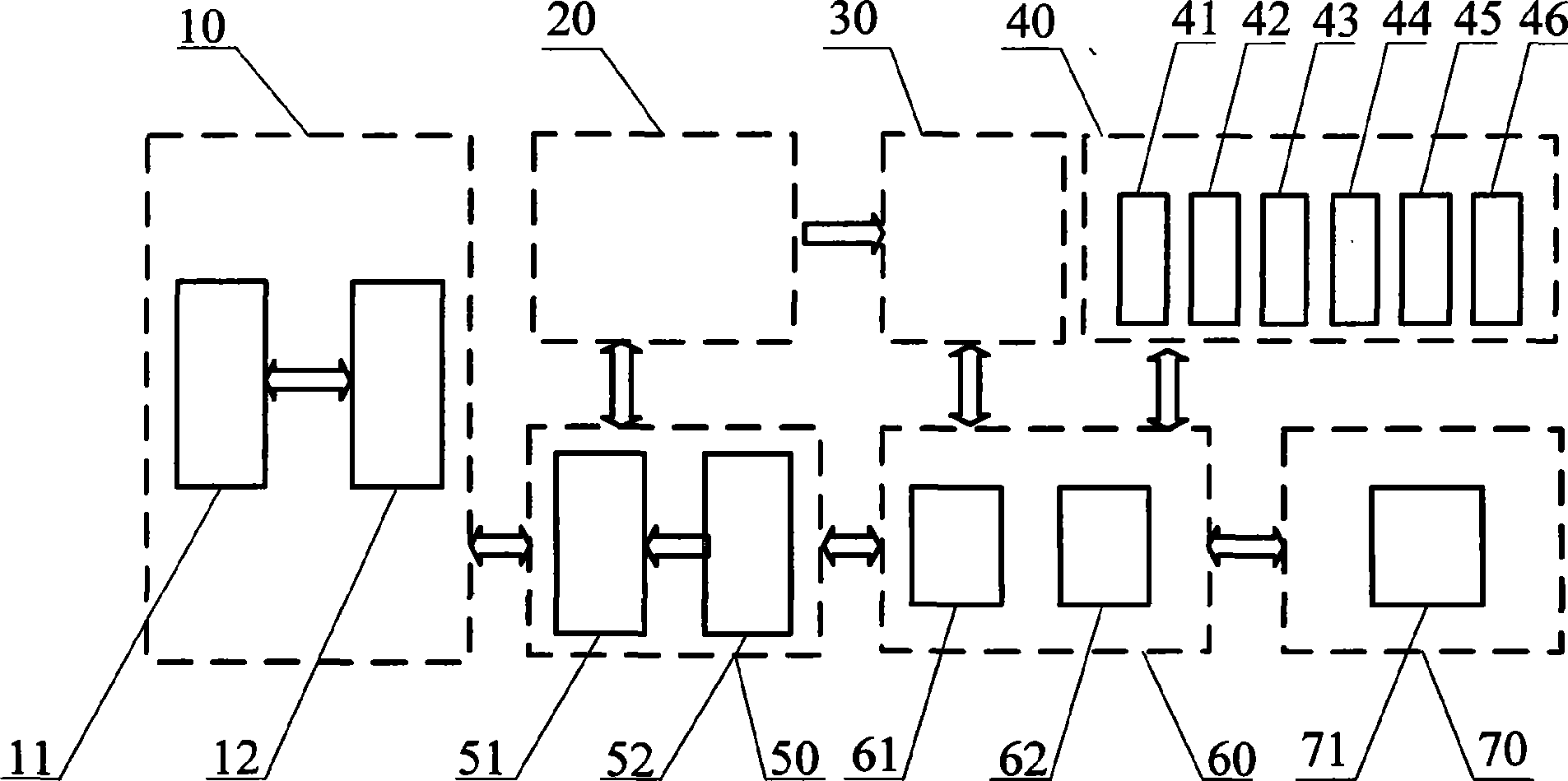

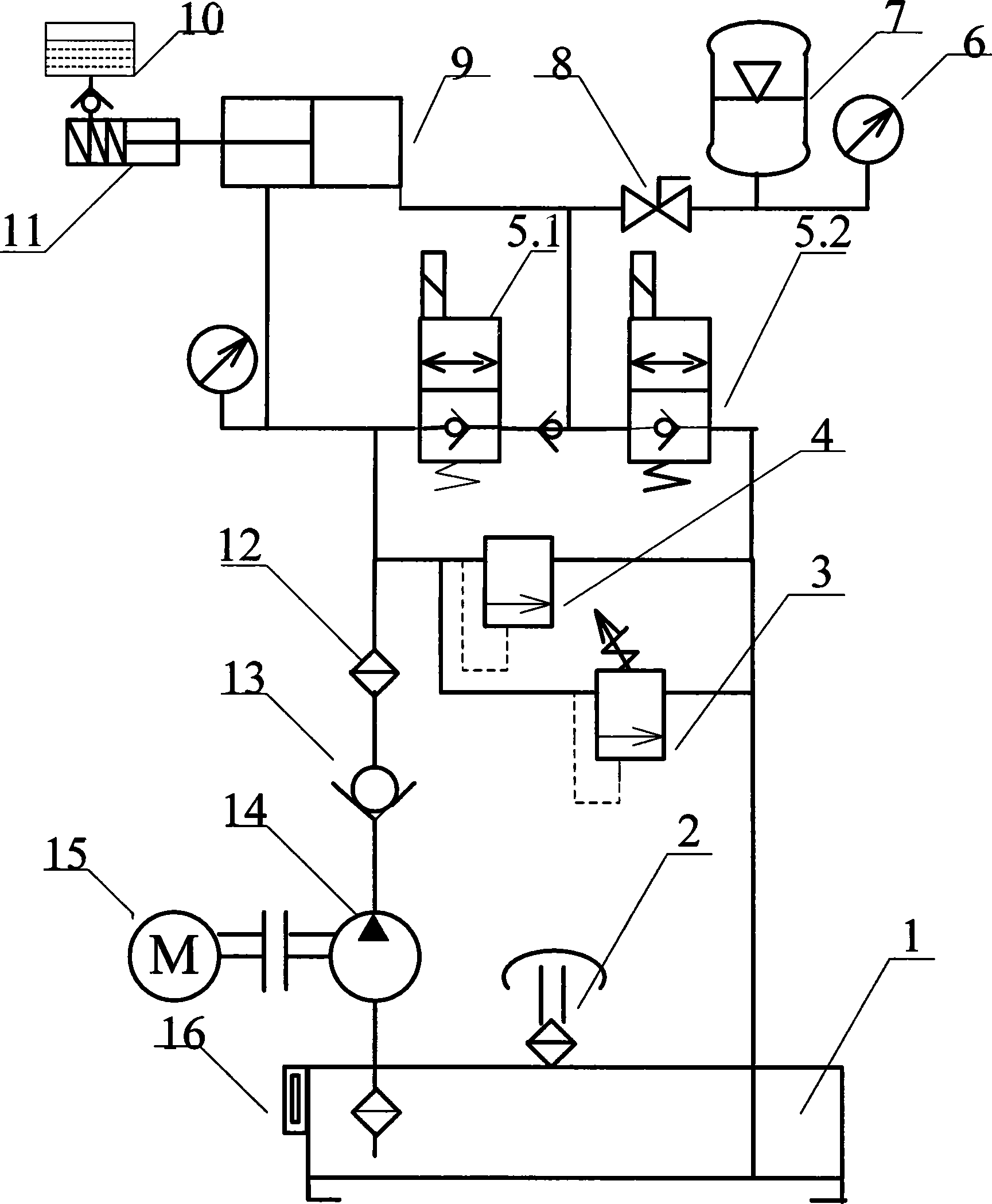

[0038] refer to figure 1 , the comprehensive performance detection device of the hydraulic ABS pressure regulator assembly involved in the present invention is controlled by the man-machine interface 11 stored in the industrial computer 10 . The test operator first selects the test items and test wheel cylinders in the man-machine interface 11, and the selected test items and test wheel cylinders are generated by the man-machine interface according to the communication protocol between the upper computer and the lower computer compiled in advance. A command code, through the RS232 serial port The bus is transmitted to the hydraulic ABS solenoid valve drive circuit 20, and the hydraulic ABS solenoid valve drive circuit 20 identifies the code, and controls each component of the comprehensive performance detection device of the hydraulic ABS pressure regulator assembly acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com