Apparatus and method for producing transparent conductive oxide film

An oxide thin film, transparent and conductive technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of increasing equipment cost and increasing equipment complexity, and reduce equipment cost, energy and density Controllable, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

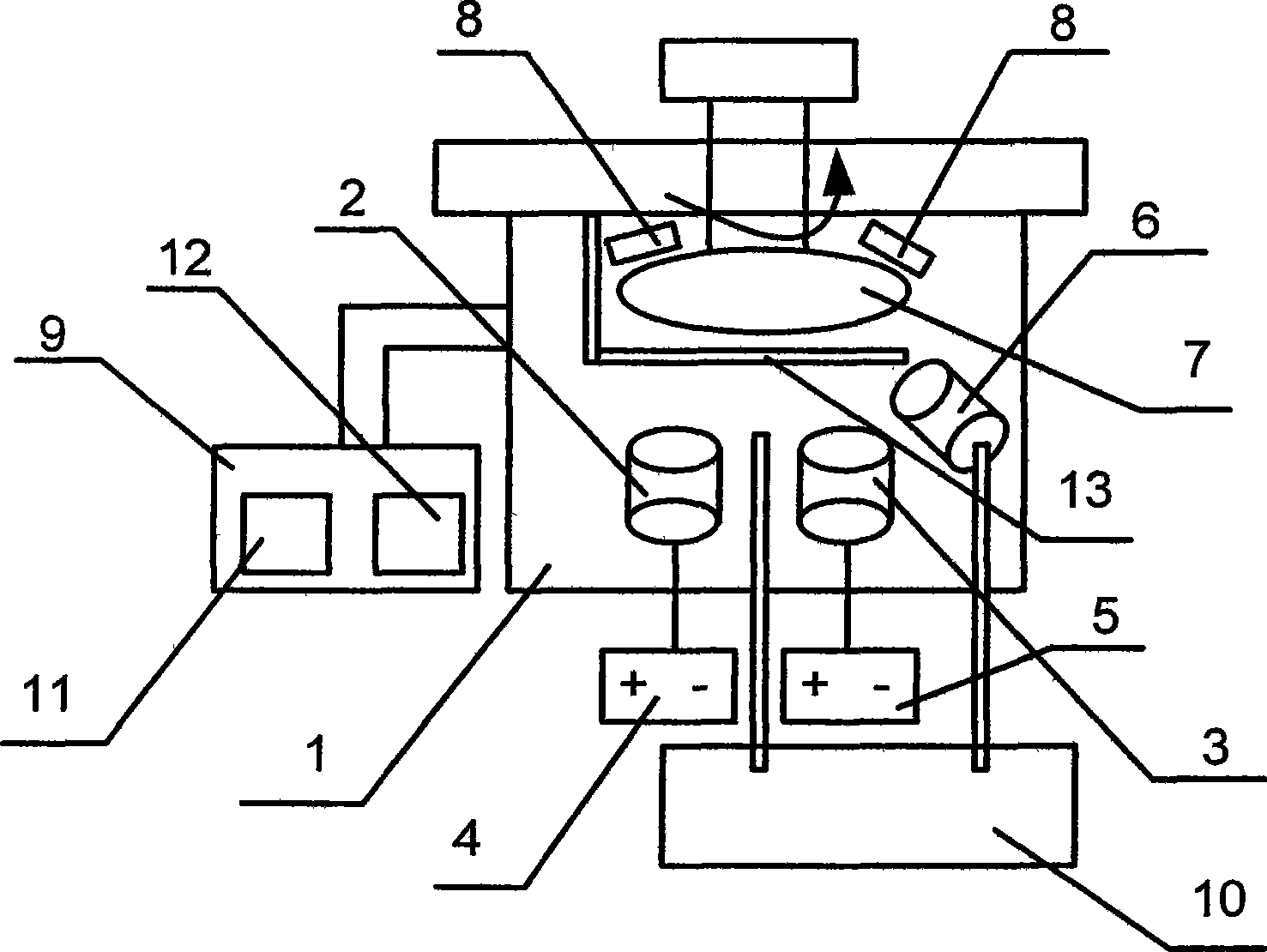

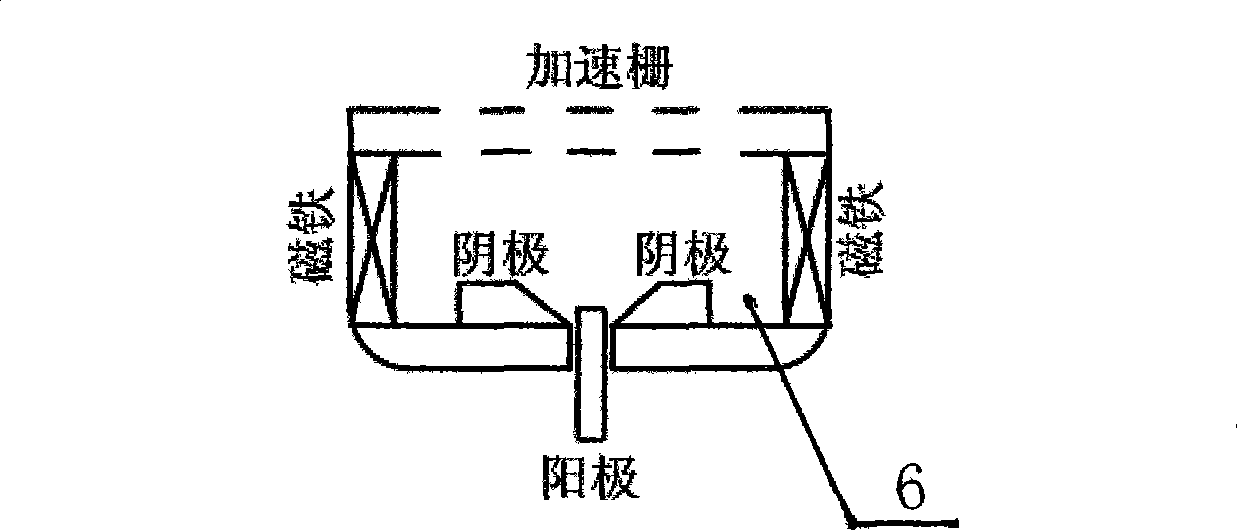

[0032] The present invention will be further described and elaborated below in conjunction with the accompanying drawings. figure 2 Shown is a schematic structural diagram of a preferred embodiment of the preparation equipment of the transparent conductive oxide film provided by the present invention, including: a closed reaction chamber or a vacuum chamber 1, the reaction chamber 1 is made of austenitic stainless steel or non-magnetic material, and is horizontal Type arrangement, also can be vertical. It is equipped with a vacuum system 9 and an intake system 10; the vacuum system 9 is composed of a mechanical pump 11 and a molecular pump or a cryopump 12, which can vacuumize the reaction chamber to 10 -6 -10 -7 Torr (vacuum degree). A movable substrate frame 7 is arranged at the middle position of the upper part of the reaction chamber, and the substrate frame 7 is disc-shaped, square, or barrel-shaped. A heater 8 is provided on the back of the substrate frame 7, and a b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com