Encapsulating material applied to LED and method of preparing the same

A technology of light-emitting diodes and packaging materials, applied in chemical instruments and methods, other chemical processes, electrical components, etc., can solve problems such as stability, transparency reduction, unfavorable colloid potting operation, poor colloid yellowing resistance, etc., to achieve durability Good yellowing property, good for long-term use stability, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the encapsulation material applied to light-emitting diodes comprises the following steps:

[0031] (1) Dissolve 5g of vinyl silicone resin in 100g of xylene, and stir until all vinyl silicone resin is dissolved in xylene to form a solution; the structural formula of vinyl silicone resin used is (Me 3 SiO 0.5 ) 39 (Me 2 ViSiO 0.5 ) 2 (SiO 2 ) 51 (where Me represents methyl, Vi represents vinyl);

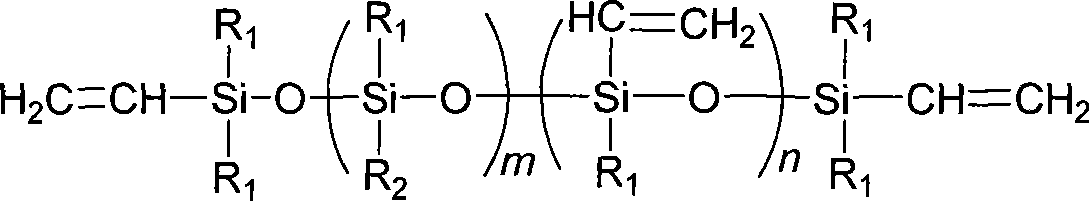

[0032] (2) Dissolve 100g of vinyl siloxane in 100g of xylene and stir until all vinyl siloxane is dissolved in xylene to form a solution; the structural formula of vinyl siloxane used is

[0033]

[0034] where m=100, n=3

[0035] (3) The solution obtained in step (1) is mixed with the solution obtained in step (2), and stirred evenly, then xylene is removed therein to form 105g liquid;

[0036] (4) The liquid obtained in step (3) is mixed with 0.02g inhibitor (both methylpentynyl alcohol), 0.5g platinum acid vinyl siloxane complex with a ...

Embodiment 2

[0042] The preparation method of the encapsulation material applied to light-emitting diodes comprises the following steps:

[0043] (1) Dissolve 30g of vinyl silicone resin in 100g of toluene, and stir until all vinyl silicone resin is dissolved in toluene to form a solution; the structural formula of vinyl silicone resin used is (Me 3 SiO 0.5 ) 25 (Et 2 ViSiO 0.5 ) 4 (SiO 2 )51 (where Me represents methyl, Et represents ethyl, Vi represents vinyl);

[0044] (2) Dissolve 100g vinyl siloxane in 200g toluene and stir until all vinyl siloxane is dissolved in toluene to form a solution; the structural formula of vinyl siloxane used is

[0045]

[0046] where m=11, n=3

[0047] (3) Mix the solution obtained in step (1) with the solution obtained in step (2), and stir evenly, then remove the toluene therein to form 130g of liquid;

[0048] (4) the liquid that step (3) obtains is mixed with the isopropanol complex of chloroplatinic acid of 3000ppm with the content of 0.1g...

Embodiment 3

[0054] The preparation method of the encapsulation material applied to light-emitting diodes comprises the following steps:

[0055] (1) Dissolve 50g vinyl silicone resin in 100g xylene, and stir until all vinyl silicone resin is dissolved in xylene to form a solution; the structural formula of vinyl silicone resin used is (Me 3 SiO 0.5 ) 46 (Me 2 ViSiO 0.5 ) 4 (SiO 2 ) 51 (where Me represents methyl, Vi represents vinyl);

[0056] (2) Dissolve 100g of vinyl siloxane in 300g of xylene and stir until all vinyl siloxane is dissolved in xylene to form a solution; the structural formula of vinyl siloxane used is

[0057]

[0058] where m=800, n=7

[0059] (3) Mix the solution obtained in step (1) with the solution obtained in step (2), and stir evenly, then remove xylene therein to form 150g of liquid;

[0060] (4) the liquid that step (3) obtains and 0.32g inhibitor (both tetravinyltetramethylcyclotetrasiloxane), 1.6g platinum are 3000ppm chloroplatinic acid maleic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com