Modified emulsified asphalt, production method and CA mortar comprising the emulsified asphalt

A technology of emulsified asphalt and modified asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of CA mortar quality fluctuations, different settling speeds, and increased production costs, so as to improve storage stability and facilitate transportation and storage, reducing production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of preparation method of high-speed railway or light rail slab ballastless track CA mortar special modified emulsified asphalt, it comprises the following steps:

[0018] Step 1: Prepare modified asphalt by using ordinary asphalt.

[0019] The common asphalt is selected from commercially available common petroleum asphalt, coal tar pitch or natural asphalt, preferably with a penetration of 4.0-14.0mm at 25°C, a ring and ball softening point of 40-60°C, and a ductility of 80-200cm at 15°C. of asphalt. In this example, commercially available No. 90 Sinopec Zhenhai Heavy Traffic Road Asphalt was selected.

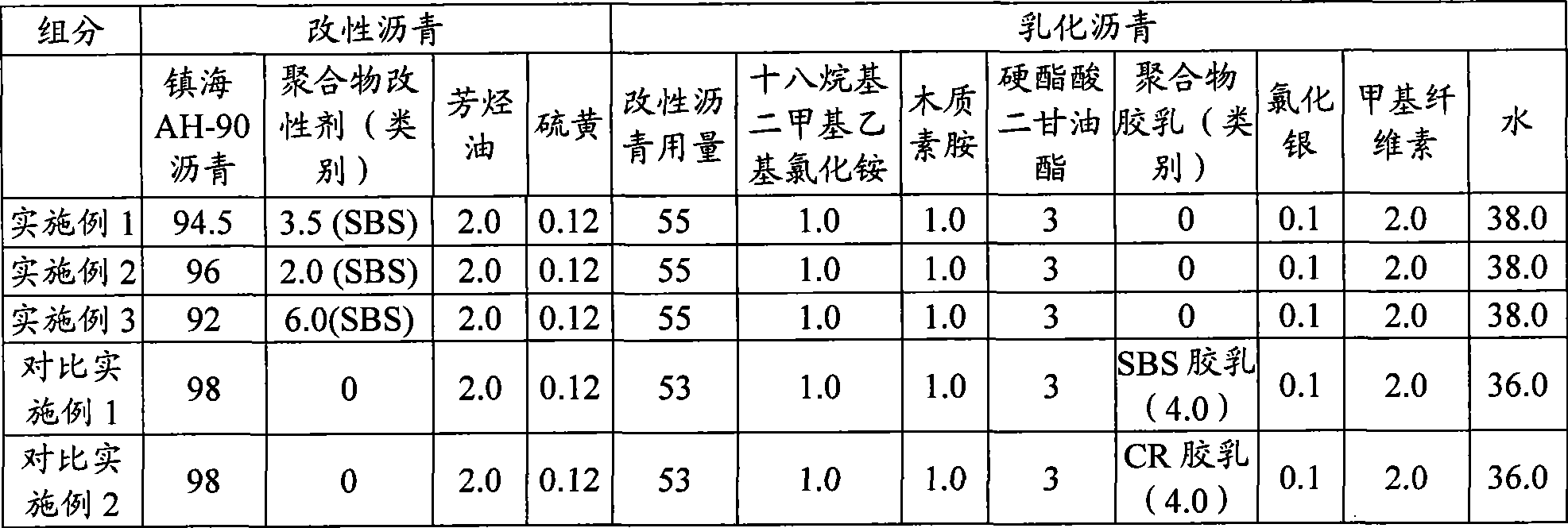

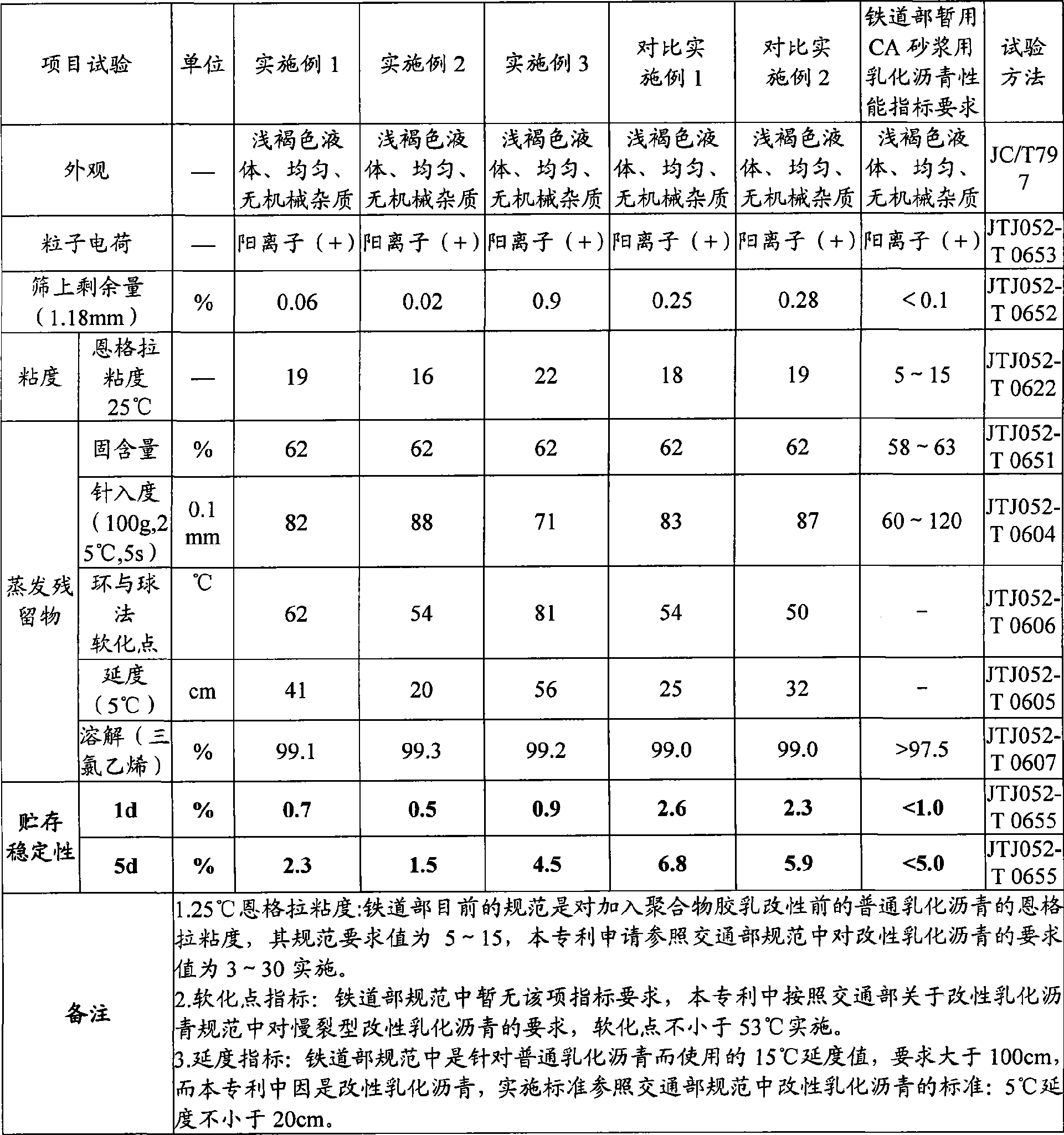

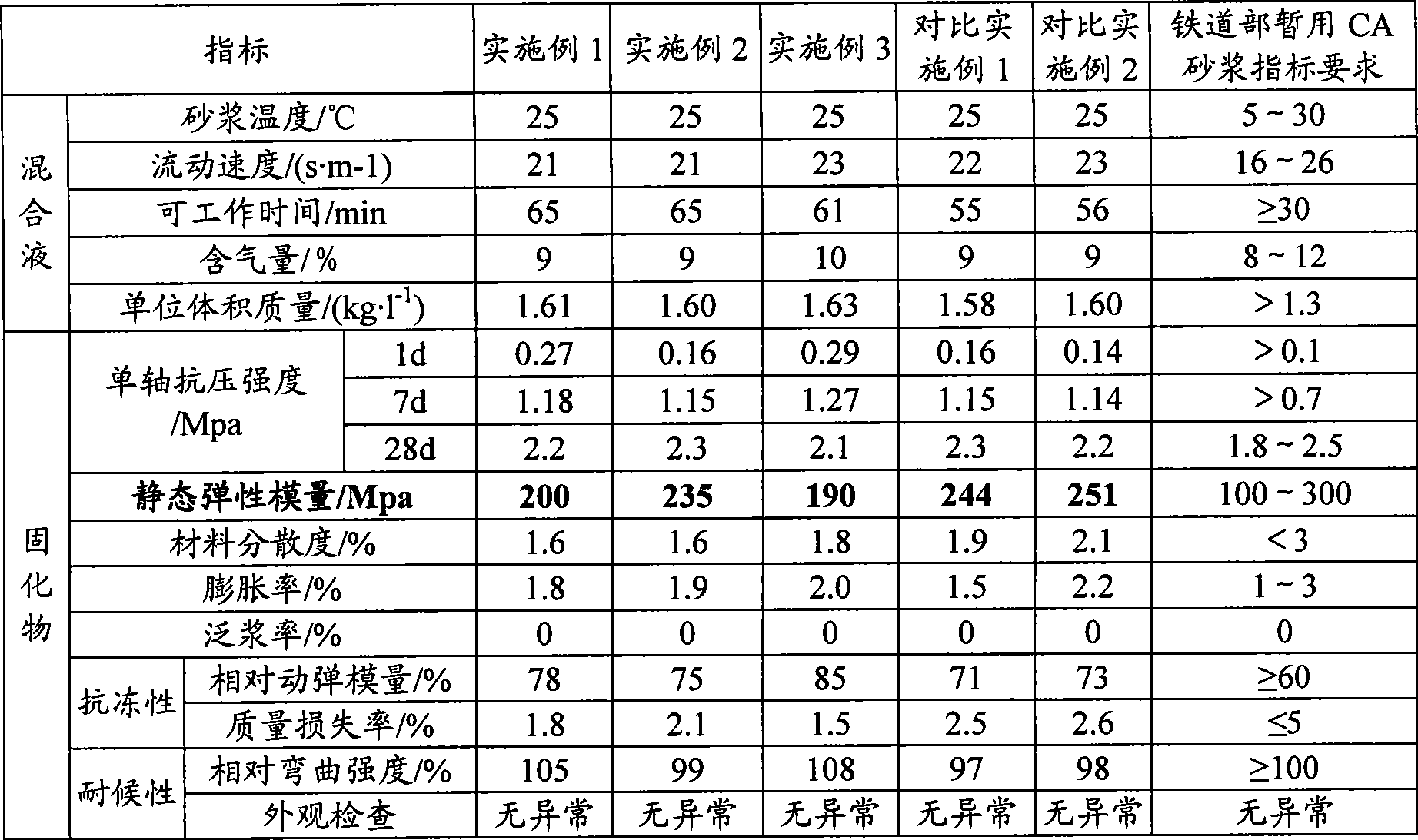

[0020] The preparation of the modified asphalt includes: in parts by weight, mixing 94.5 parts of No. 90 Sinopec Zhenhai Heavy Traffic Road Asphalt, 3.5 parts of SBS791H particles (linear structure, molecular weight about 110,000) produced by polymer modifier Yuehua, compatible Add 2 parts of aromatic oil extracted from Jinan Oil Refinery, 0.12 parts of modifie...

Embodiment 2

[0027] Except that the polymer modifier used in the preparation of modified asphalt is 2.0 parts of SBS, and No. 90 Sinopec Zhenhai Heavy Traffic Road Asphalt is 96 parts, the types, proportions and production technology of modified asphalt of the other components are compared with Example 1 same.

Embodiment 3

[0029] Except that the polymer modifier used in the preparation of modified asphalt is 6 parts of SBS, and No. 90 Sinopec Zhenhai heavy traffic asphalt is 92 parts, the types, proportions and production process of modified asphalt are the same as in Example 1 .

[0030] It is worth mentioning that the proportions of the components in the modified emulsified asphalt provided in the above examples are not limited thereto, and those skilled in the art can flexibly adjust the proportions of the components according to actual needs, as long as the modified emulsified asphalt is satisfied by weight ratio. Sexual emulsified asphalt includes 45% to 65% of modified asphalt, 0.5% to 10% of cationic surfactant, 0.5% to 10% of nonionic surfactant, 0.1% to 10.0% of auxiliary agent, and the balance is water; the modified asphalt It includes 82.0-96.0% of base asphalt, 2-6% of polymer modifier, 0-10.0% of compatibilizer and 0-2.0% of modified asphalt stabilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com