Method for producing cement expansive material by using flying ash, desulfurized gypsum from incineration of refuse

A technology for waste incineration fly ash and desulfurization gypsum, applied in cement production and other directions, can solve problems such as accumulated defects, climate, soil, plant and human health hazards, secondary pollution of desulfurization gypsum, etc., to ensure product performance, good economy and society. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment.

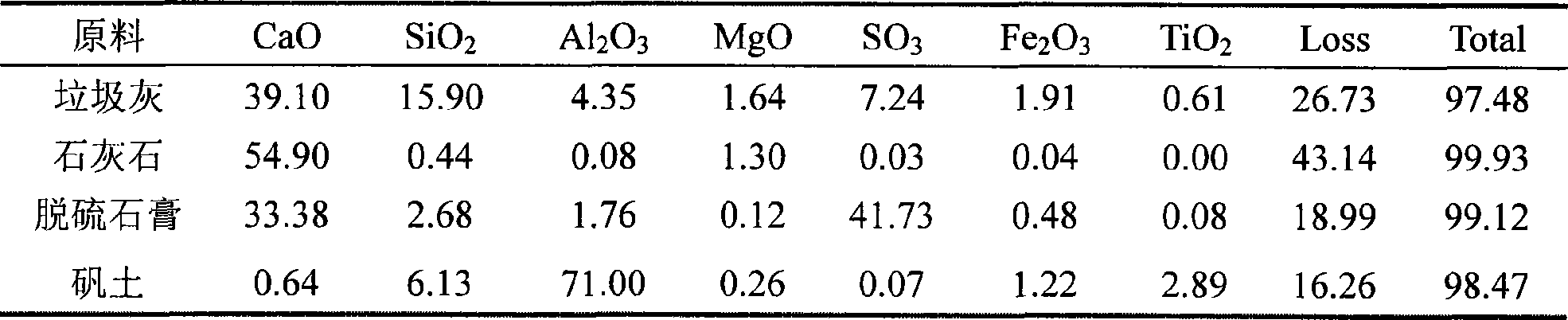

[0025] The main raw materials used in the test are desulfurization gypsum, waste incineration fly ash, limestone, and alumina. The main chemical composition of the raw material is shown in Table 1

[0026] Table 1 Chemical Composition / % of Raw Materials

[0027]

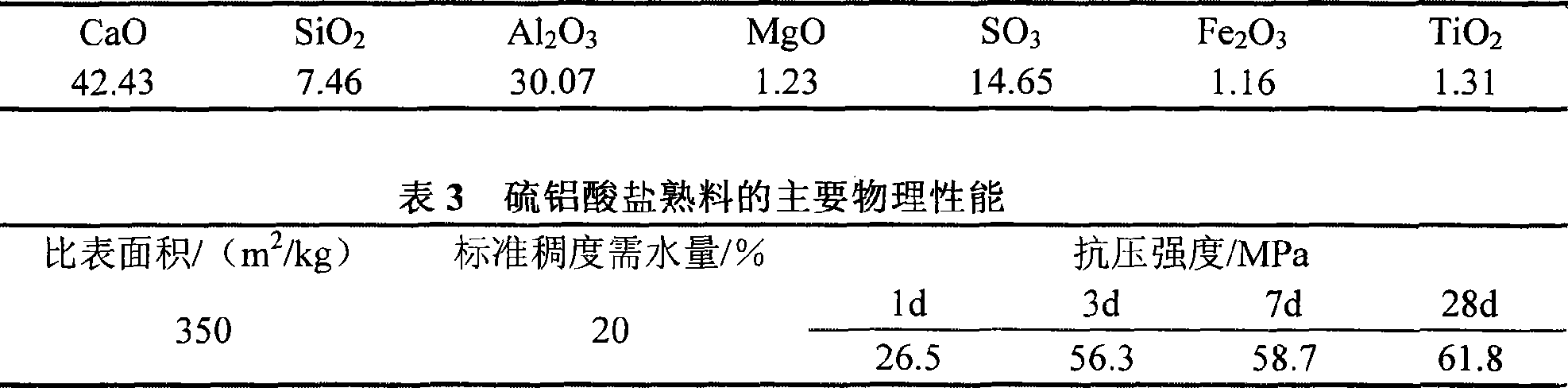

[0028] Calculated according to the designed mineral clinker composition: garbage ash: 15%; limestone: 36%; desulfurized gypsum: 19%; bauxite: 30%. The raw materials in the above ratio were calcined in an electric furnace at 1200° C. for 1 hour at a heating rate of 30° C. / min, and then taken out for rapid cooling. The chemical composition of sulphoaluminate clinker is shown in Table 2, and the physical properties of sulphoaluminate clinker are shown in Table 3.

[0029] Table 2 Main chemical components of sulphoaluminate clinker / %

[0030]

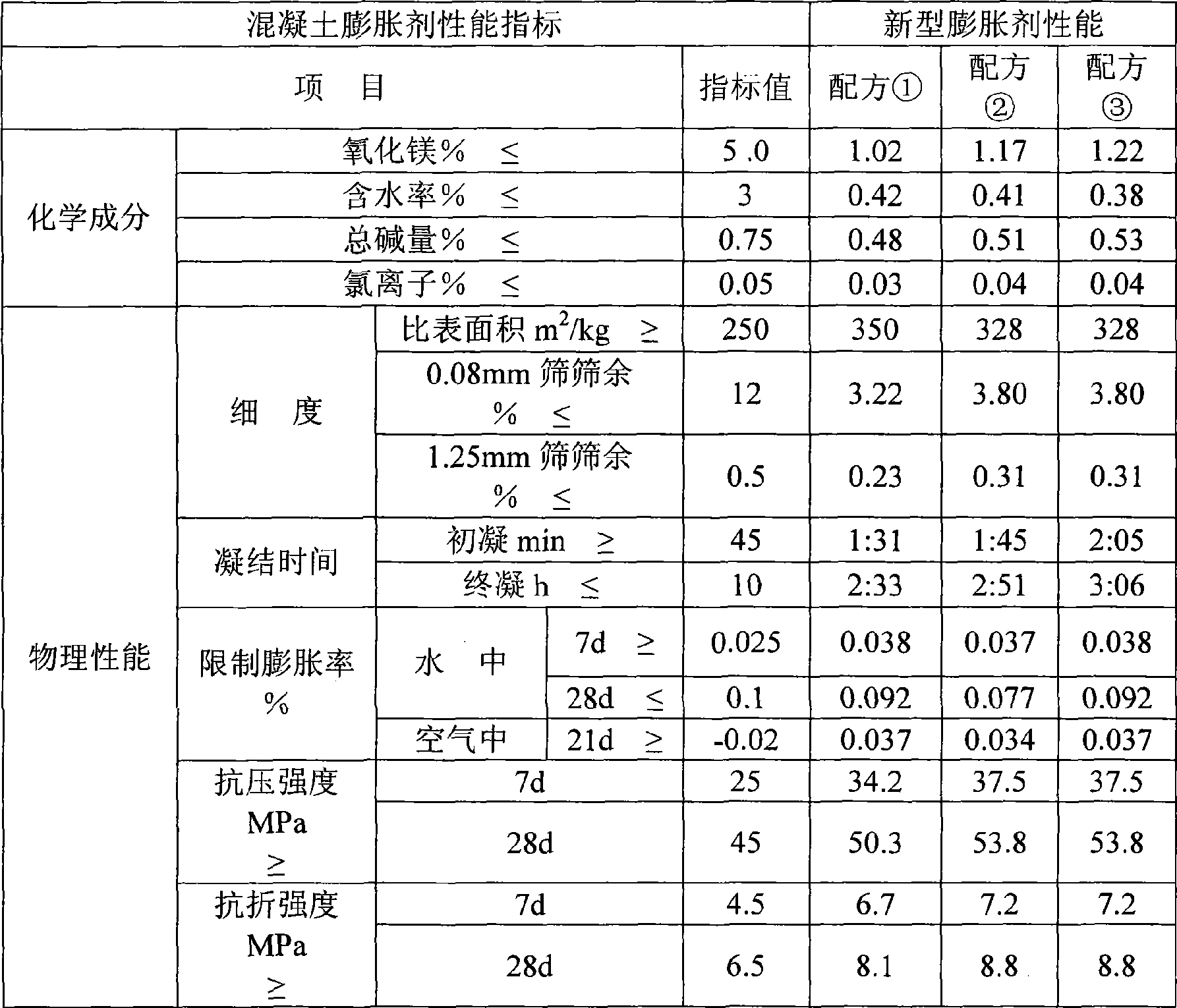

[0031] Grind the calcined sulfoaluminate clinker and desulfurized gypsum t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com