Production technique and device of large-area viscose cat litter paper-box

A production process and large-area technology, applied in carton/carton manufacturing machinery, packaging, paper, etc., can solve the problems of uneven clamping force, affecting product quality, grinding out blood bubbles, etc., and achieve high production efficiency , shorten the working hours, and smooth the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

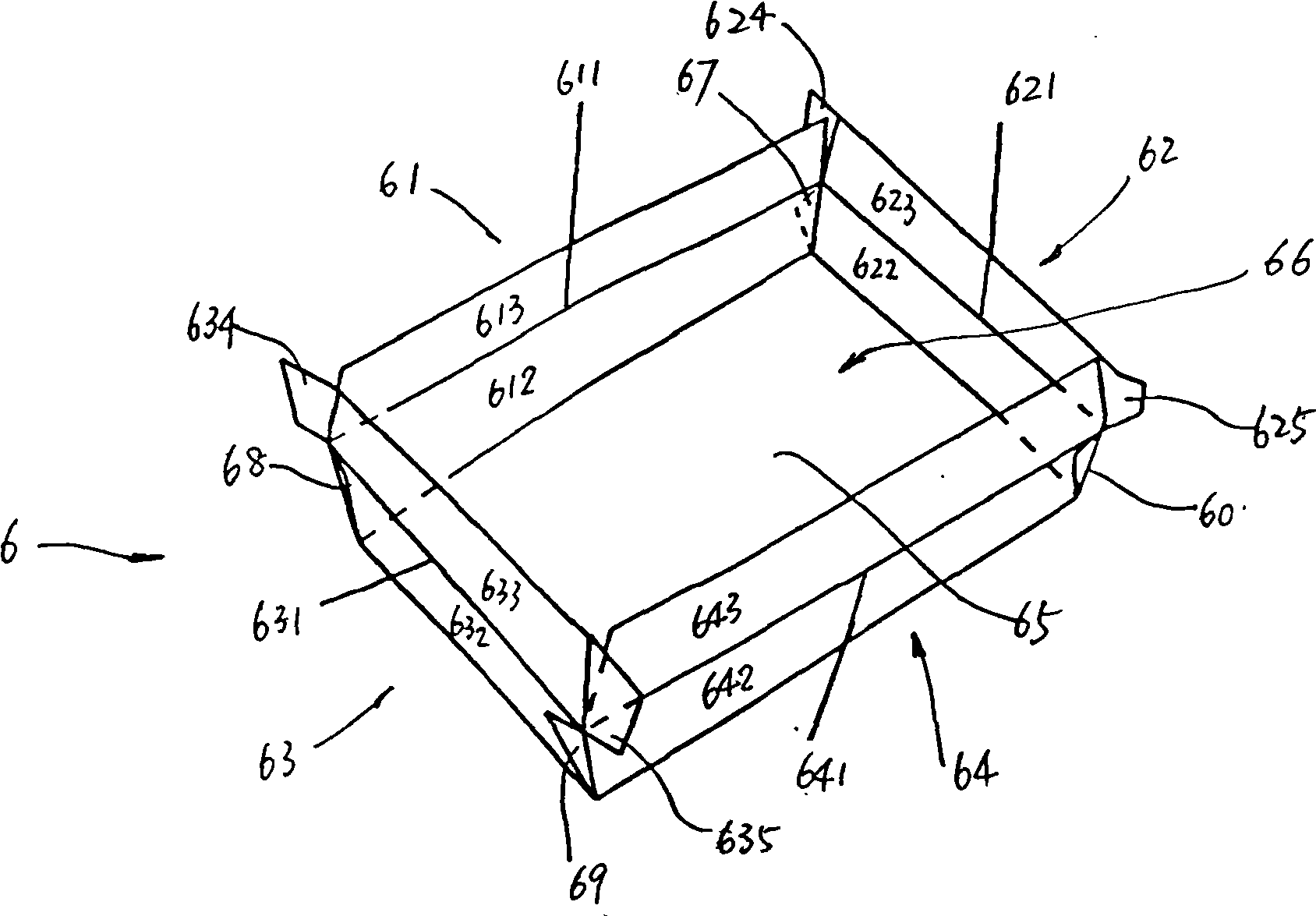

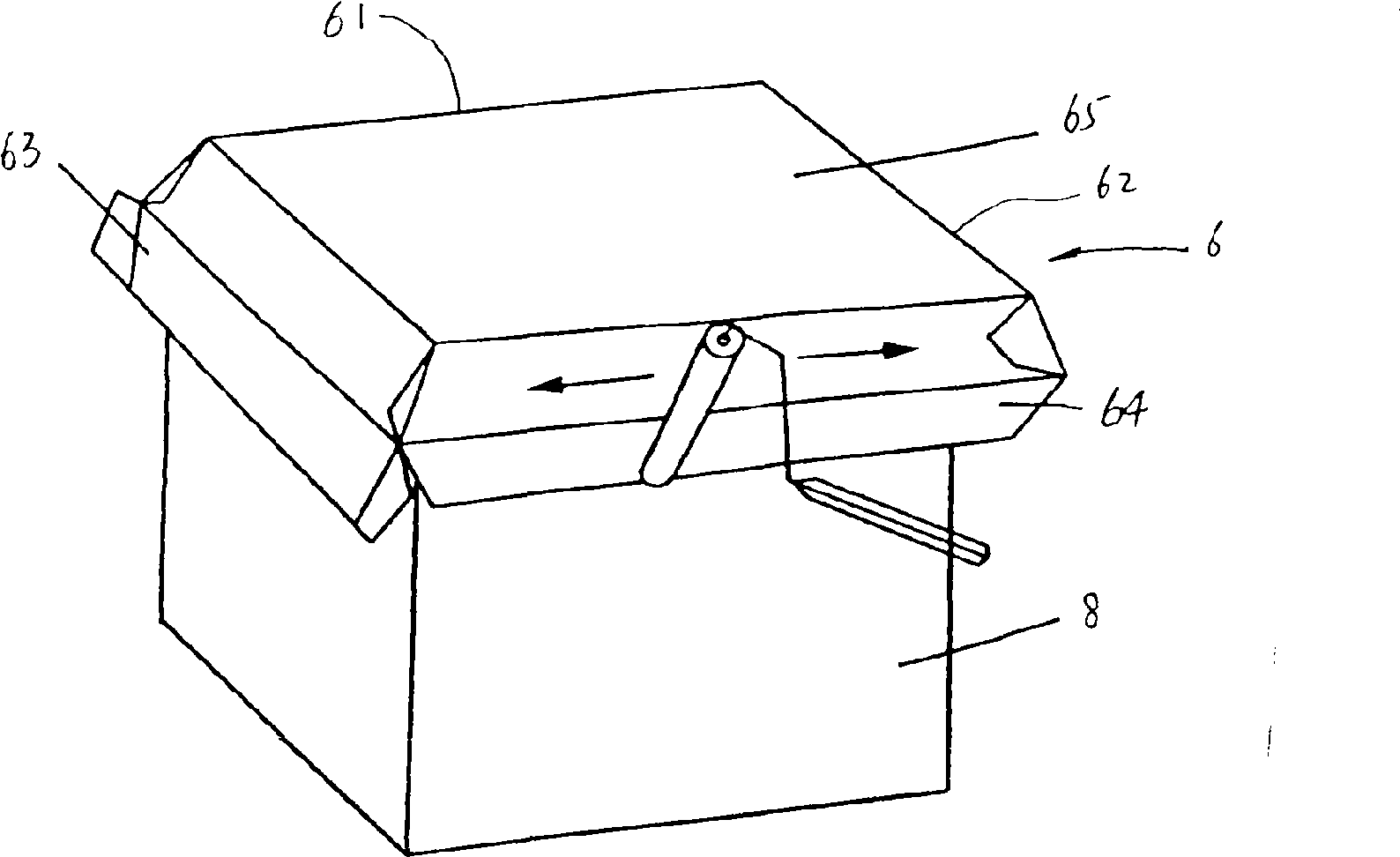

[0044] A production process of a large-area viscose cat litter box. The cat litter box is a kind of cardboard that is covered with a layer of waterproof film on one side and then glued. It is made of a bottom surface 65, two long sides 61, 64. A box body with an opening 66 composed of two short sides 62 and 63. The production process includes die-cutting and crimping, large-area gluing and crimping, including the following steps:

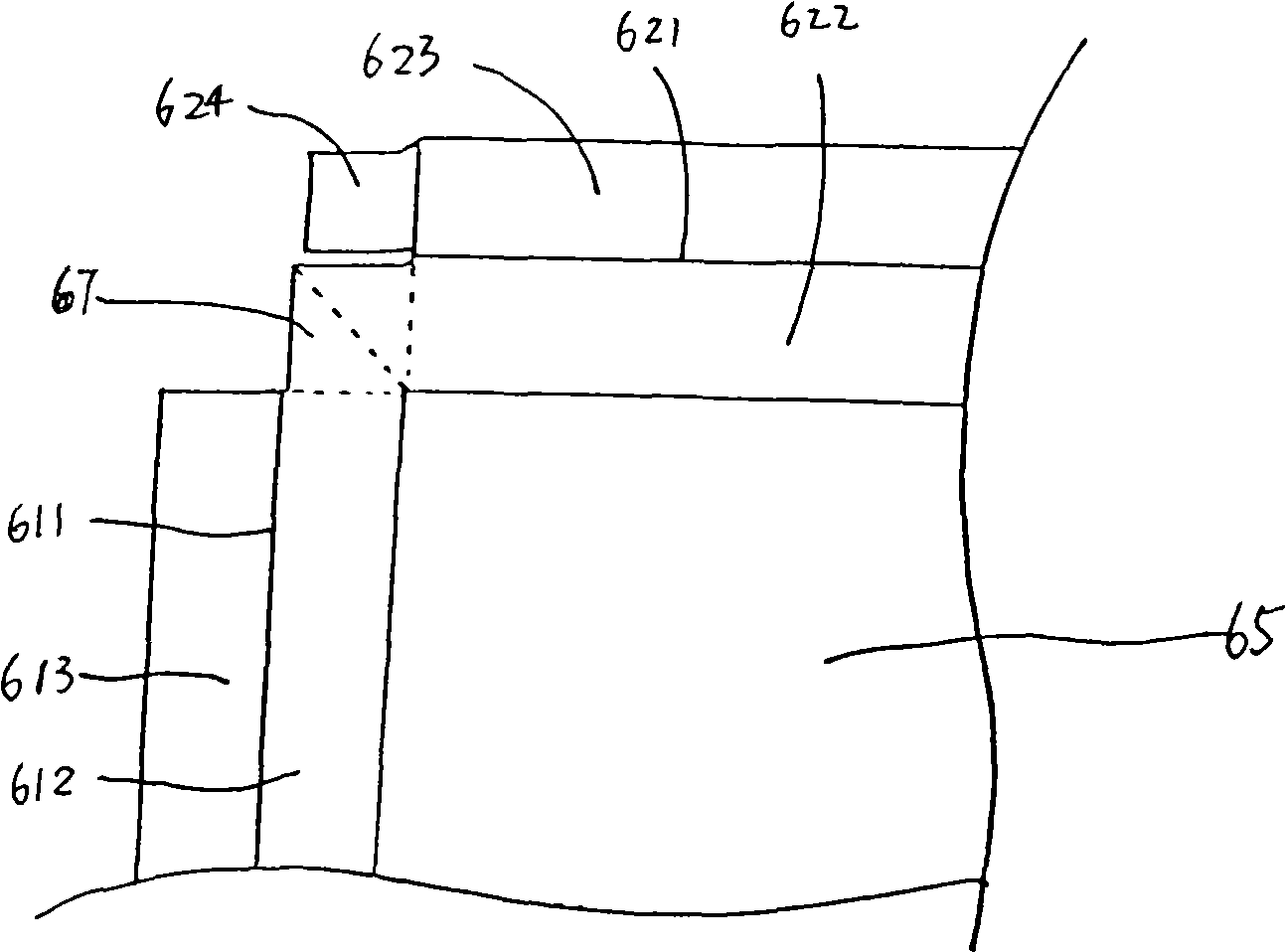

[0045] The first step: if figure 1 , figure 2 As shown, the entire sheet of cardboard covered with a layer of waterproof film is die-cut and crimped to form a bottom surface 65 and two long sides 61 and 64 with middle fold lines 611 and 641, which are formed from the middle fold lines 611 and 641. Upper side 613,643 and lower side 612,642, two short sides 62,63 that are pressed with middle folding line 621,631, form upper side 623,633 and lower side 622,632 from middle folding line 621,631, and the corresponding 45° connecting angles 67, 68, 69, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com