Laser scanner

A laser scanner and laser source technology, applied in the field of laser scanners, can solve problems such as complex rotating joints and easy failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

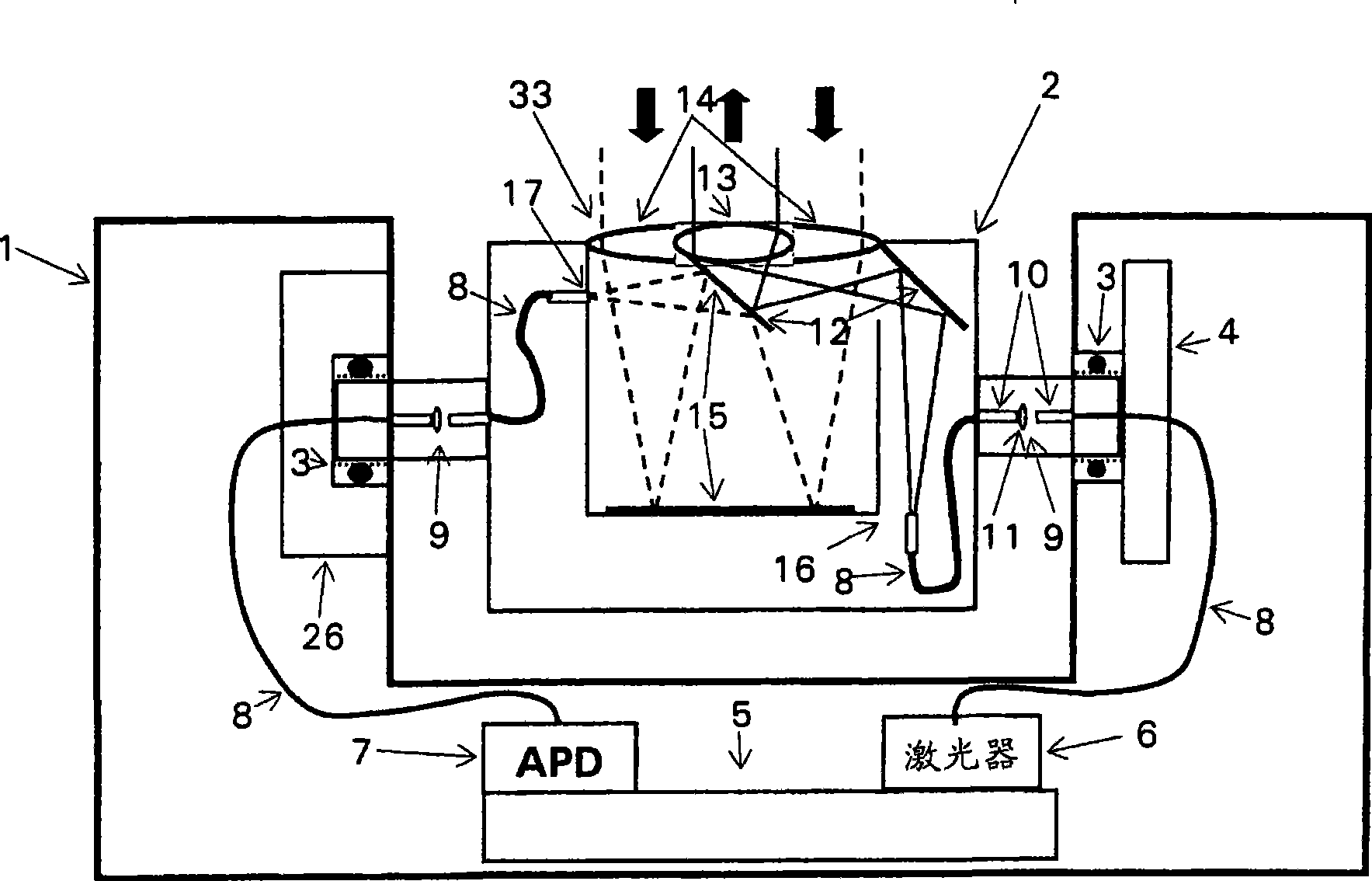

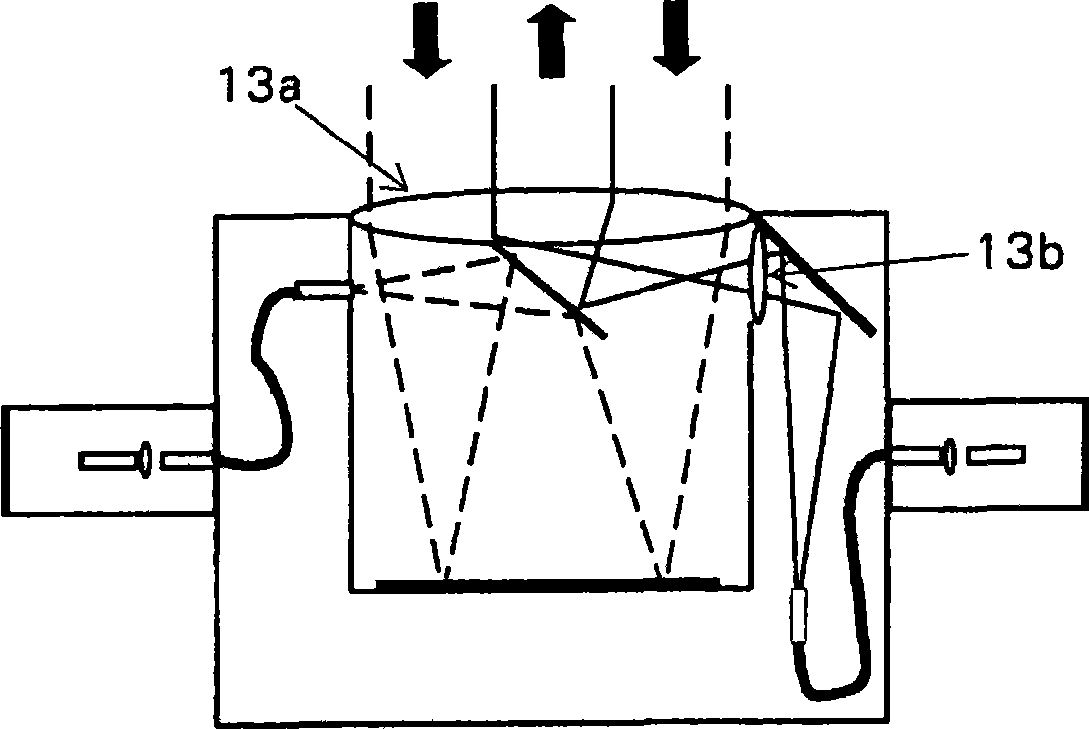

[0029] figure 1 A rotor 1 is shown in which a rotating body 2 is mounted on a rotating bearing 3 so as to be rotatable about a horizontal axis. The rotor 1 can be moved about a vertical axis by means of a first rotary drive not shown here, so that the rotational position can be determined by means of a first angle measuring device. The rotary body 2 is rotated by the second rotary driver 26 . The rotational position of the rotating body 2 is detected by means of the second angle measuring device 4 . The evaluation electronics 5 in the rotor 1 are connected to a laser source 6 (laser) and a laser detector 7 (APD) of the distance measuring device.

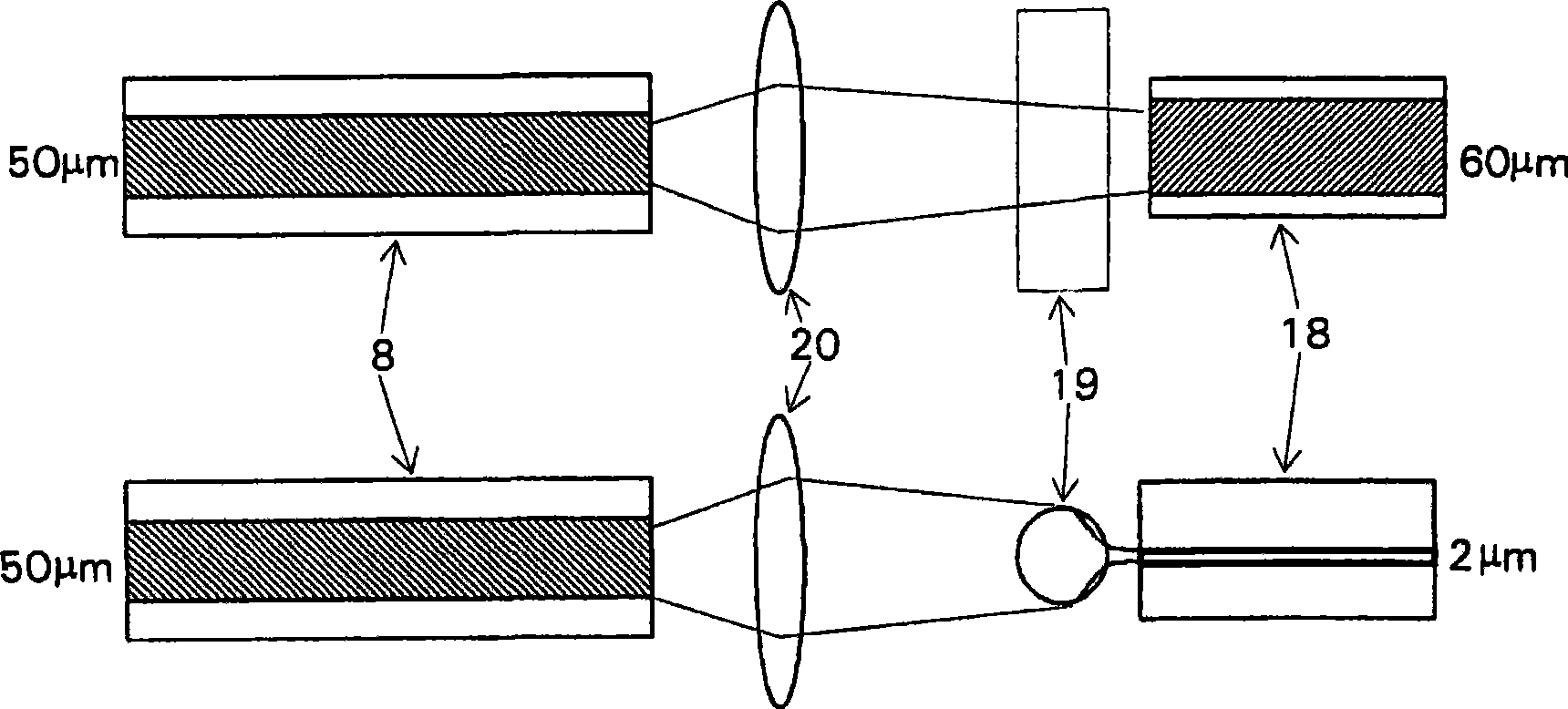

[0030] The laser light emitted from the laser 6 is sent from the laser source 6 to the optical link 9 between the rotor 1 and the rotating body 2 through the waveguide 8 in the rotor. A multimode fiber having a core diameter of, for example, 50 μm and a numerical aperture of, for example, 0.12 is suitable for this purpose.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com