Sand bed seepage flow sludge plugging simulation apparatus

A technology for simulating devices and seepage, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of not being able to simulate the lifting cleaning and recharging process, not being able to provide enough data for the study of clogging mechanism, not being able to simulate solid particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

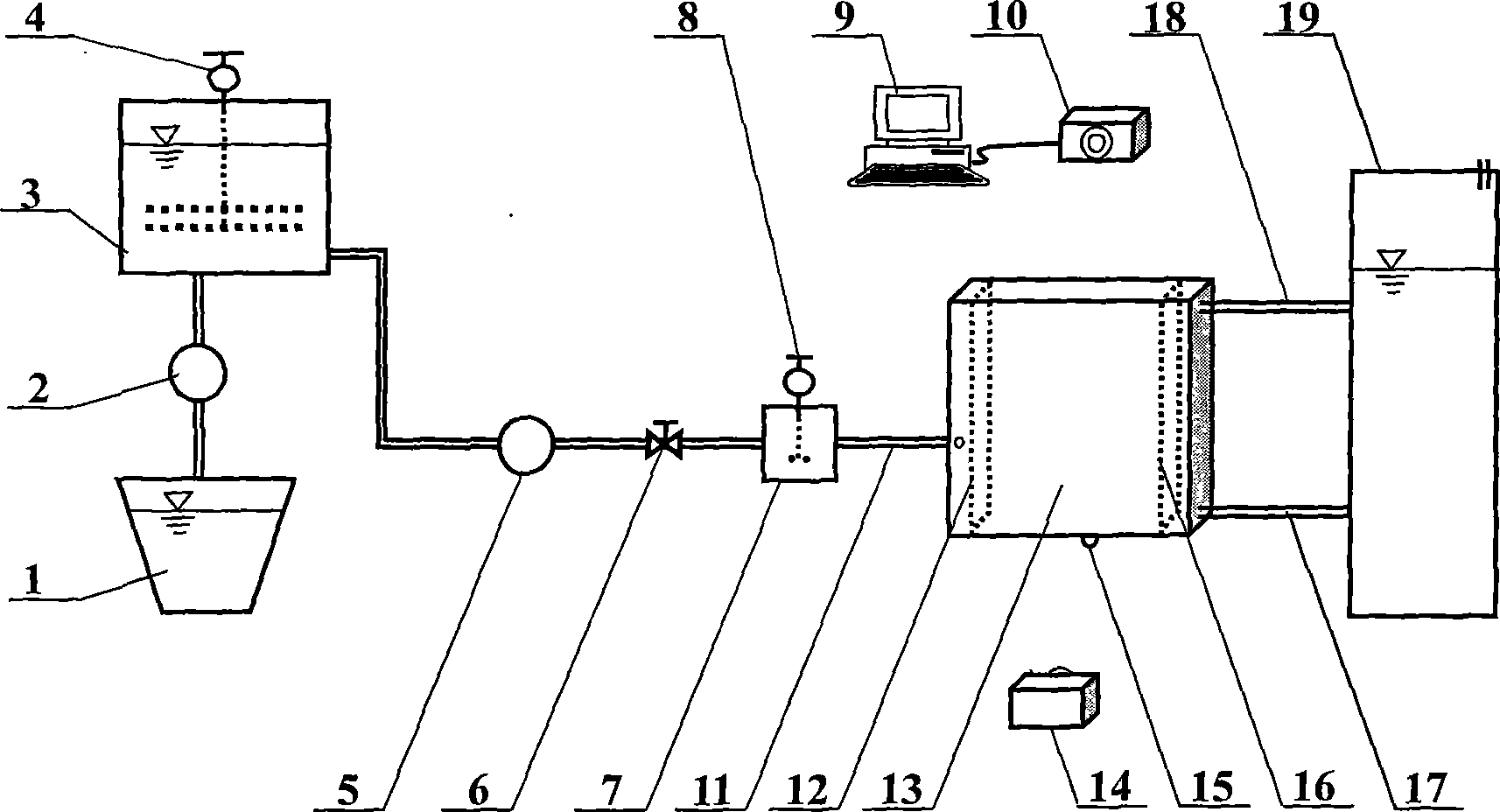

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0011] A simulation device for groundwater seepage and blockage in sand layers, comprising an upstream water storage tank 1, a control water pump 2, a water level control tank 3, an agitator 4, a return pump 5, a valve 6, an air-mixing water tank 7, a bubble generator 8, and a computer 9. First digital camera 10, water inlet pipe 11, first filter screen 12, experiment box 13, second digital camera 14, pressure measurement and sampling valve 15, second filter screen 16, lower outlet pipe 17, upper outlet pipe 18 And downstream water storage tank 19 forms. It is characterized in that an agitator 4 is installed in the water level control water tank 3, and a bubble generator 8 is installed in the air-mixing water tank 7; a first filter screen 12 and a second filter screen 16 are installed at the water inlet and water outlet of the experiment box 13, The porous media used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com