Lubrication sealing structure of rotary compressor gas cylinder

A rotary compressor and sealing structure technology, applied in the field of compressors, can solve problems such as the inability to form oil film, boundary friction of friction parts, direct gas leakage, etc., achieve the minimum sealing gap, ensure work efficiency and reliability, and improve volumetric efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

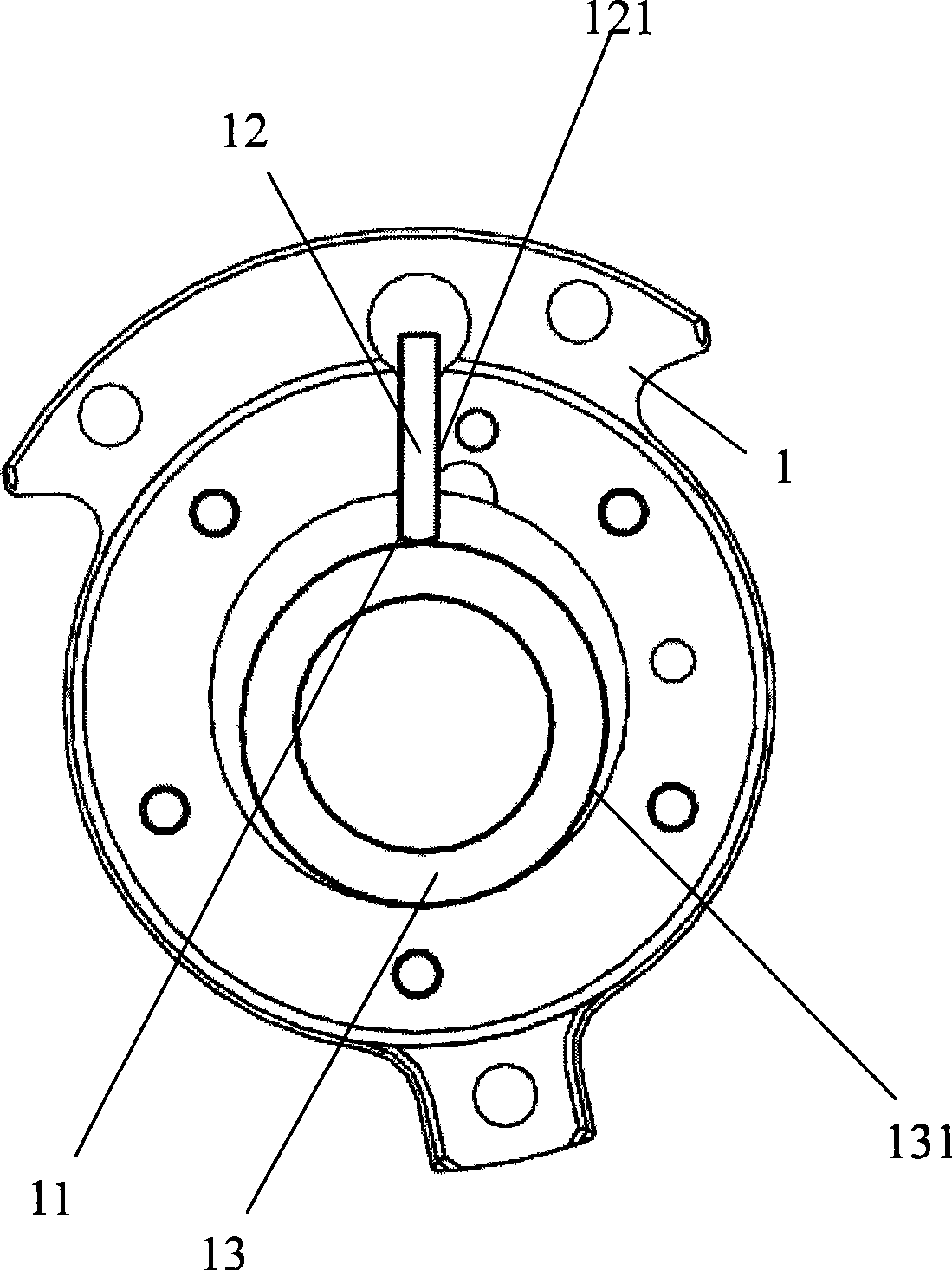

[0019] refer to figure 2 As shown, the lubricating and sealing structure of the rotary compressor cylinder of the present invention includes a cylinder block 1, the front end of the cylinder block 1 is provided with a baffle groove 11, and a baffle groove 11 is provided to separate the cylinder working chamber into a suction chamber and a The baffle 12 of the exhaust chamber and the rolling ring 13 are located in the working chamber of the cylinder; the improvement is that: the outer surface of the baffle 12 is coated with a solid lubricant layer 121; the outer surface of the rolling ring 13 is coated with a layer solid lubricant layer 131.

[0020] refer to figure 2 As shown, the lubricating and sealing structure of the rotary compressor cylinder of the present invention, wherein: the thickness of the solid lubricant layer is 0.01mm to 0.05mm; the solid lubricant is molybdenum disulfide, calcium difluoride or phosphating film.

[0021] The preparation of the lubricating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com