Thermoelectric sheet and manufacturing method thereof

A manufacturing method and technology of electric heating sheet, which are applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of cumbersome and time-consuming production, slow temperature rise, and limited temperature maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make it easier for your examiners to understand the content of the present invention and the effects that can be achieved, a specific embodiment is listed in conjunction with the illustrations, and the details are as follows:

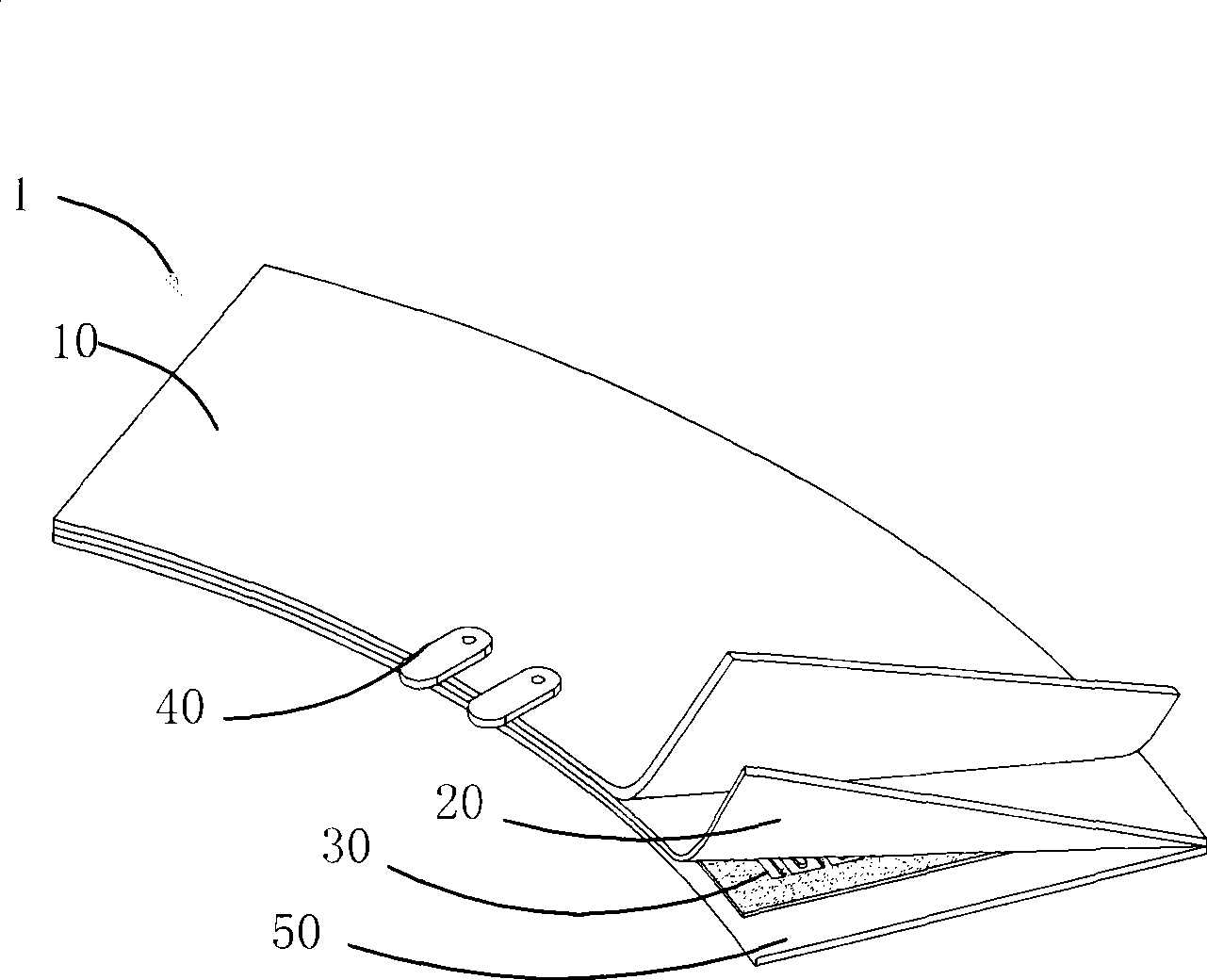

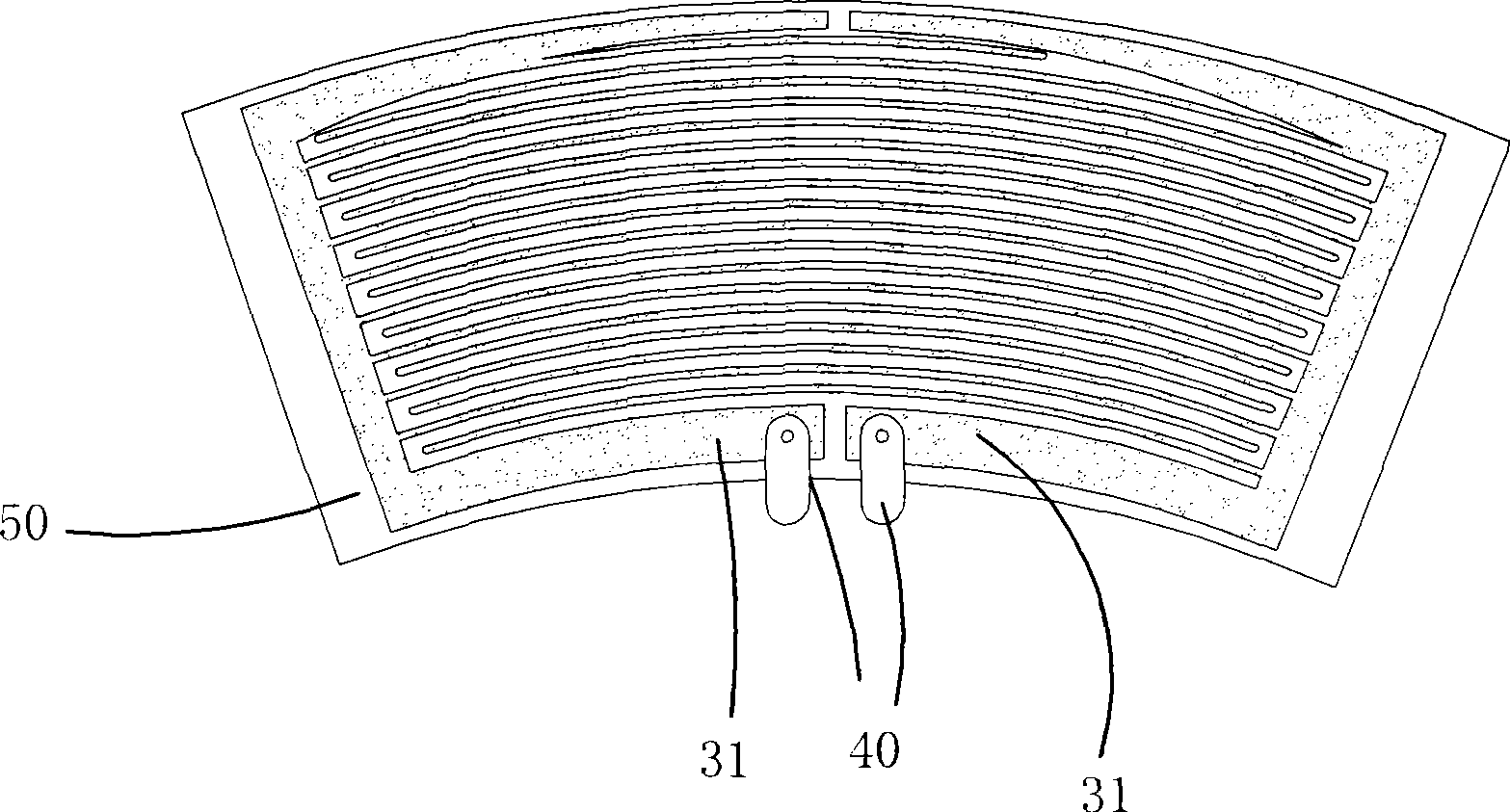

[0028] First, see figure 1 , graph and image 3 Shown is the schematic diagram of the electric heater of the present invention, the three-dimensional exploded schematic diagram and the sectional view thereof, and its electric heater 1 comprises:

[0029] A base material 10 is a windable base material, such as PET, PC, PP film or cloth, or substrates such as workpieces;

[0030] A conductive film 20, a windable film attached to one side of the substrate 10, and a conductive film with a positive temperature coefficient;

[0031] At least two conductive lines 30 are printed on one side of the conductive film 20, the two conductive lines 30 are interlaced, and the conductive film 20 and the conductive lines 30 are connected in series or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com