Cooling type multi-punch semiconductor packaging construction

A heat-dissipating, semi-conductive technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as heat sink offset, chip internal stress sealant thermal resistance, etc., to prevent peeling and increase stress Cushioning effect, the effect of improving heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

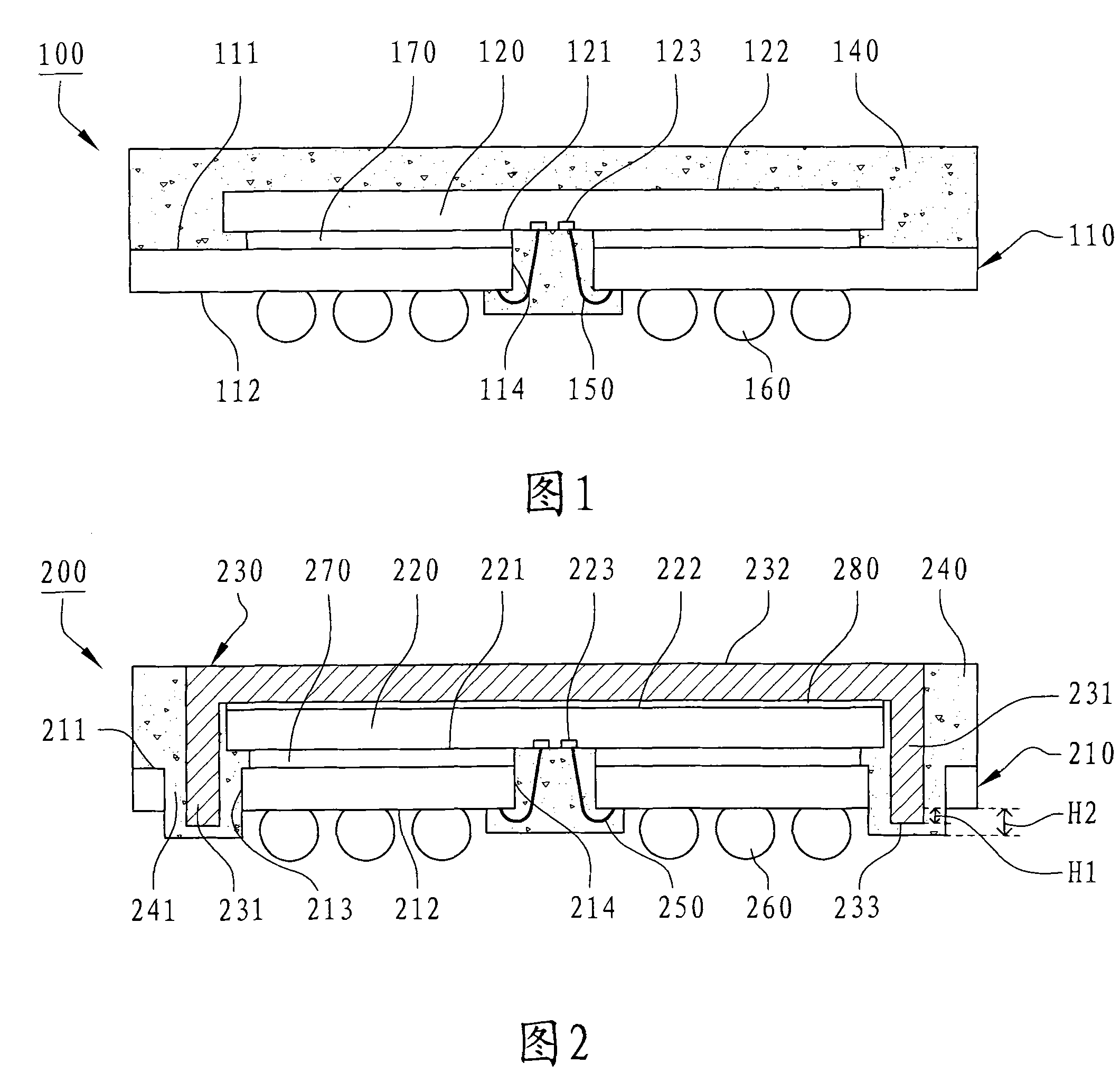

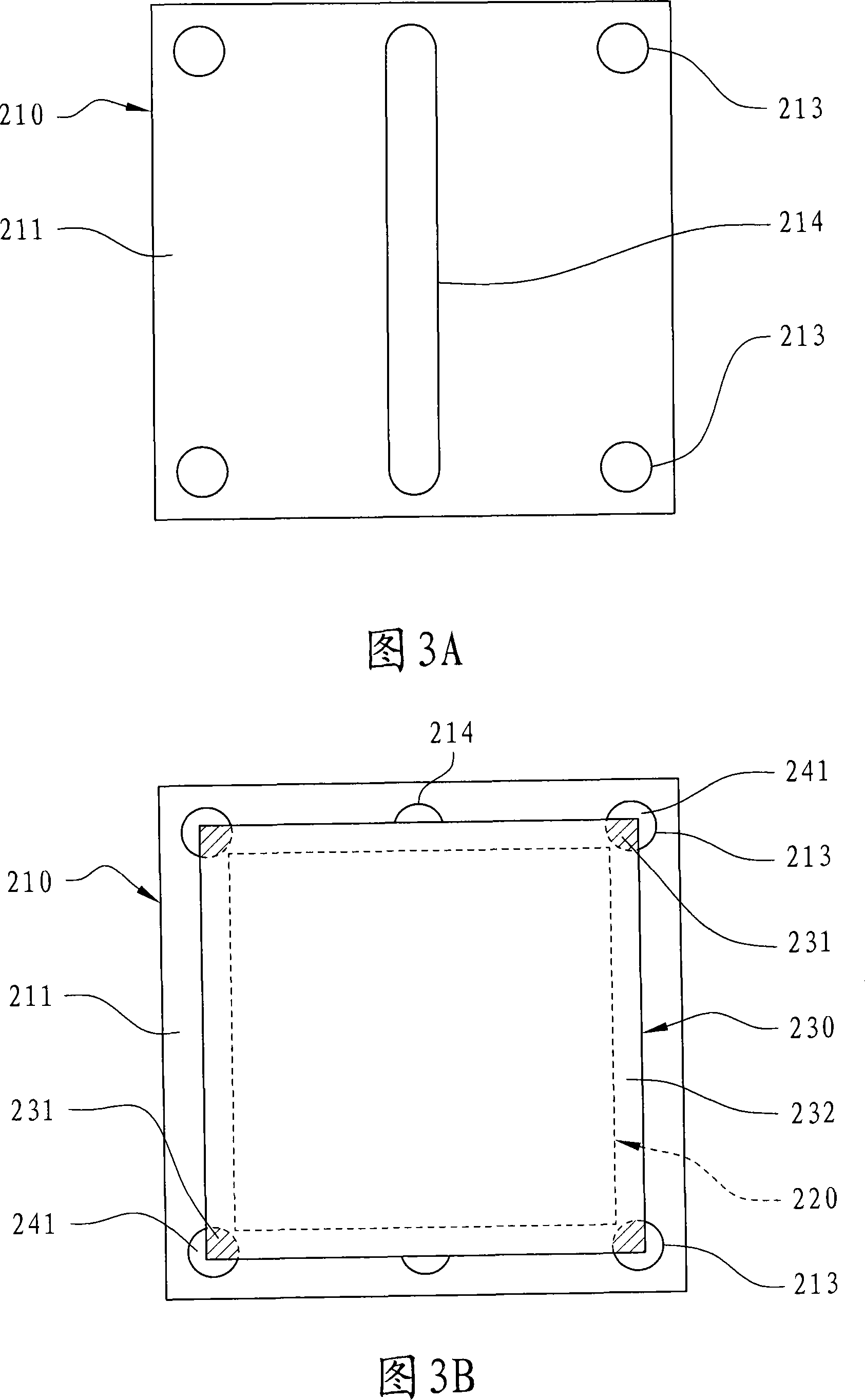

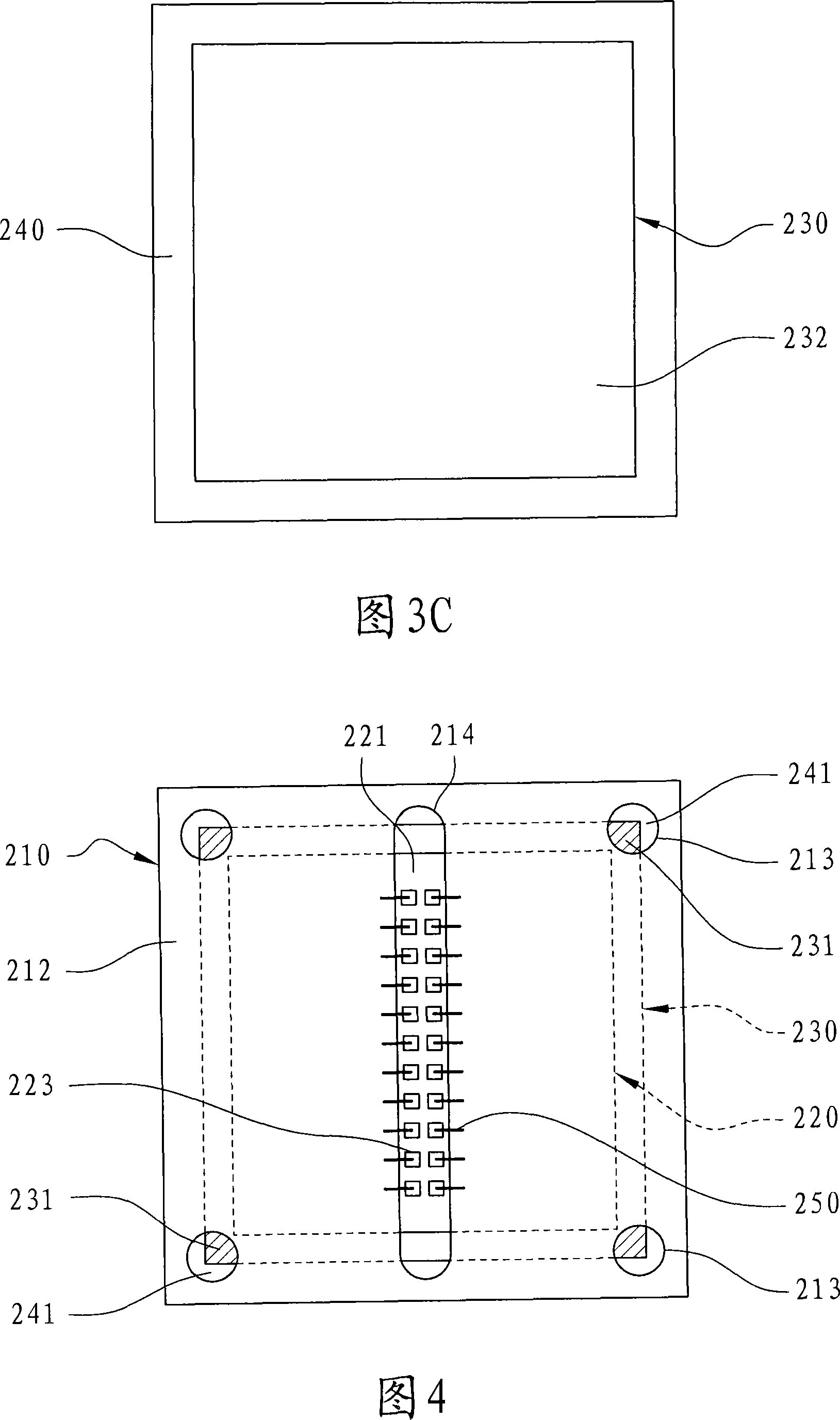

[0075] According to a first embodiment of the present invention, a heat dissipation type multi-through-hole semiconductor package structure is disclosed. see figure 2 As shown, a heat dissipation semiconductor package structure 200 with multiple through holes mainly includes a substrate 210 , a chip 220 , a built-in heat sink 230 and an encapsulant 240 . The substrate 210 has an upper surface 211 , a lower surface 212 and a plurality of positioning through holes 213 , and the positioning through holes 213 penetrate from the upper surface 211 to the lower surface 212 . In this embodiment, the positioning through holes 213 may include four corner through holes, which are adjacent to the four corners of the substrate 210 (such as Figure 3A shown). The substrate 210 may further have a slot 214 located on a central line of the substrate 210 and passing through the substrate 210 for passage of a plurality of electrical connection elements 250 in a subsequent electrical connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com