Coil used for fast impulse superconducting magnet winding structure

A technology of superconducting windings and superconducting magnets, applied in superconducting magnets/coils, usage of superconducting elements, superconducting/high-conducting conductors, etc., can solve the problems of low quench propagation speed, poor mechanical strength and stability and other problems, to achieve the effect of increasing the quench propagation speed, accelerating the quench propagation speed, and reducing the temperature of the hot spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

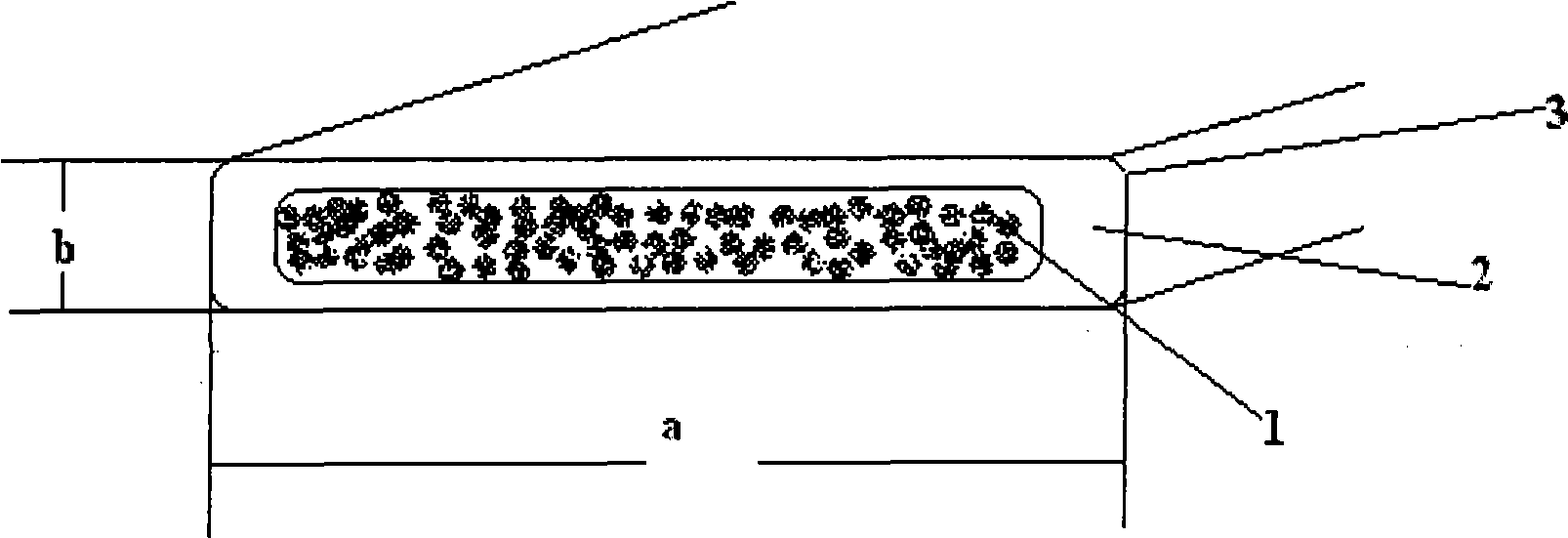

[0022] Such as figure 1 As shown, the superconducting wire used in the superconducting winding of the coil of the present invention consists of a superconductor 1 for transmitting current, a composite matrix 2 composed of CuNi and copper with good stability, and an external insulating layer 3 . The superconductor (1) is wrapped with a composite matrix (2) composed of CuNi and copper, and the composite matrix (2) is covered with an insulating layer (3). The ratio of the width a to the thickness b of the superconducting wire is greater than 2.5 to ensure the stability of the structure.

[0023] Such as Figure 2a and Figure 2b Shown is the structure of the coil of the present invention. The skeleton 4 is usually made of epoxy glass fiber reinforced plastic or stainless steel. There are more holes on the skeleton 4 for the passage of liquid he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com