Online fault monitoring system for power transformer

A technology for power transformers and monitoring systems, applied in directions such as ultrasonic/sonic/infrasonic generation, can solve problems such as unsatisfactory gas selectivity, poor linearity, and large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

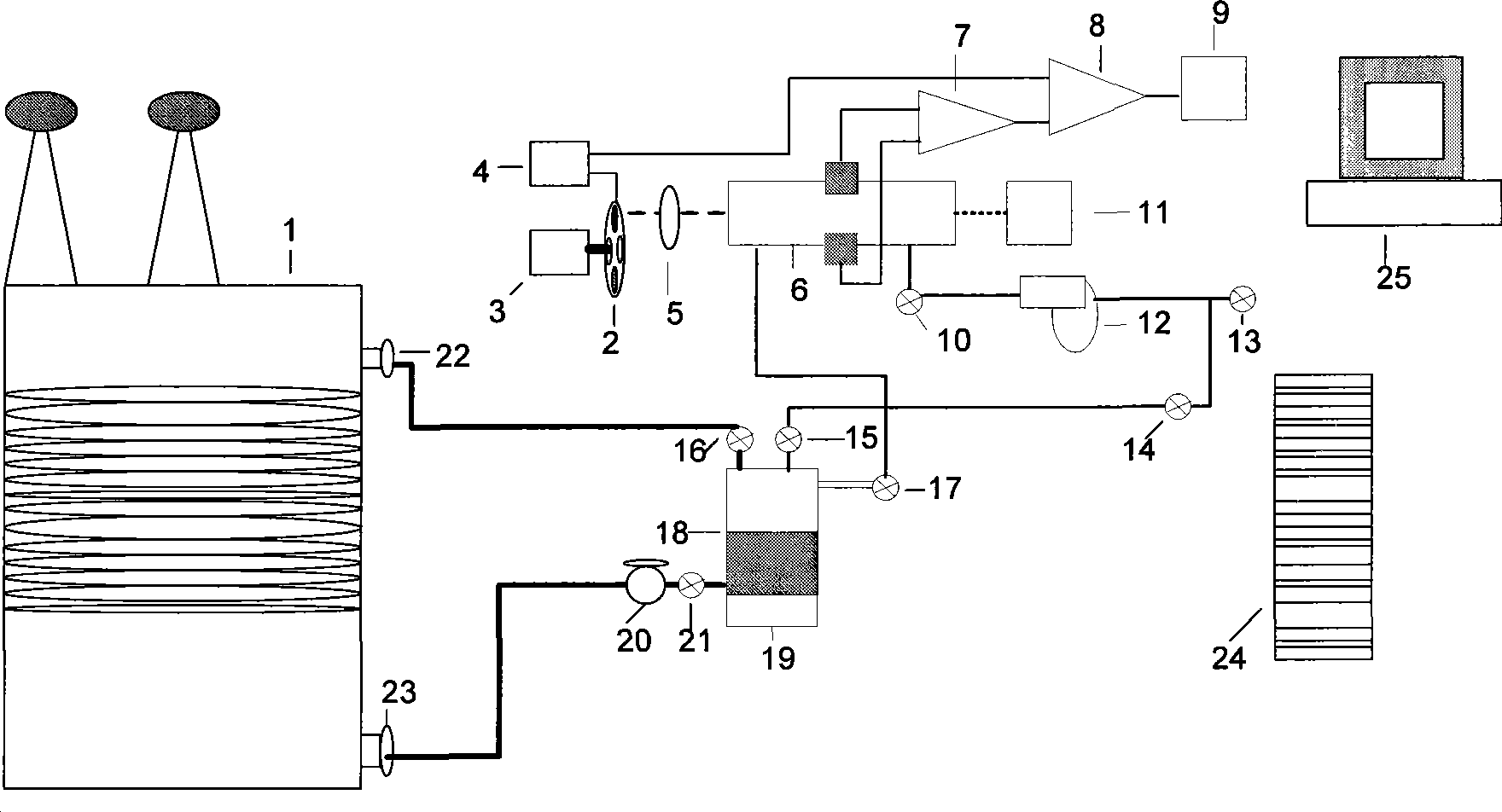

[0022] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

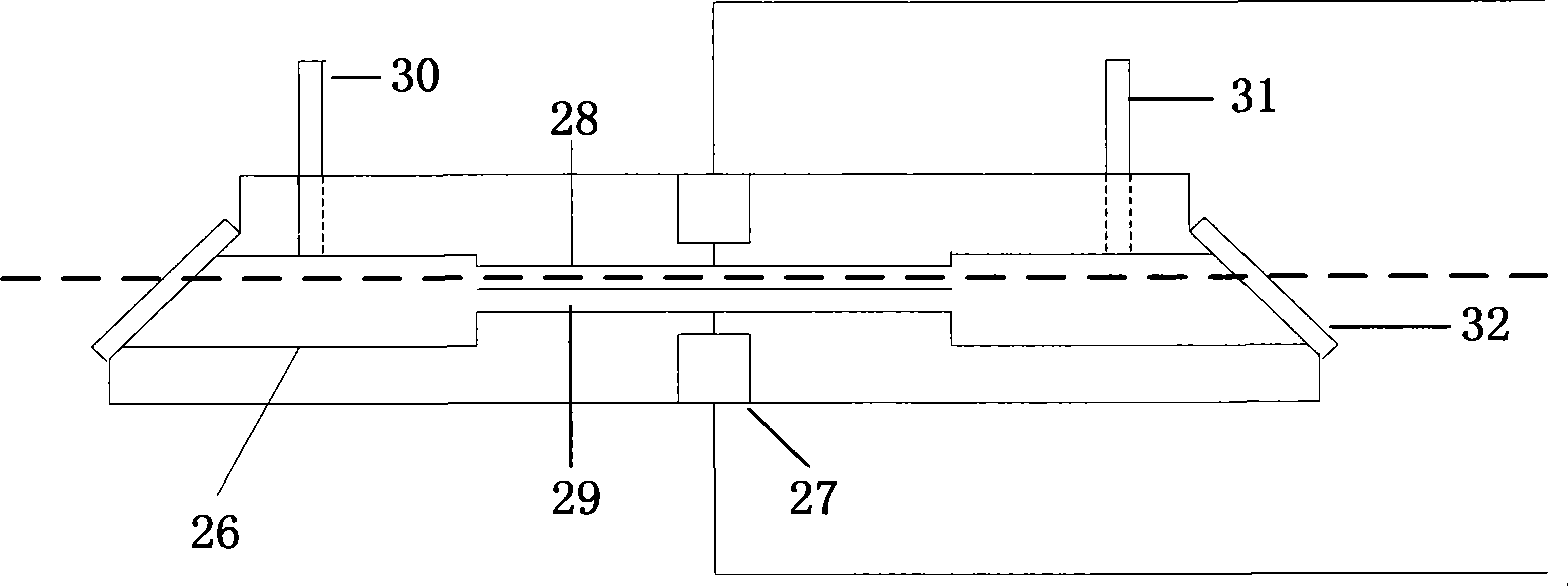

[0023] like figure 1 As shown, this embodiment includes: transformer 1, tunable cascaded diode laser 2, stepper motor 3, diode laser power controller 4, convex lens 5, photoacoustic cavity 6, differential amplifier 7, lock-in amplifier 8, data acquisition Card and digital recorder 9, laser power meter 11, electric vacuum pump 12, oil-gas separation chamber 18, ultrasonic oscillator 19, oil return pump 20, PLC controller 24, computer 25.

[0024] The oil-gas separation chamber 18 is located at the bottom of the whole system. Its oil inlet is connected to the oil valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com