Method for detecting ethylene or ethylene propylene rubber content in ethylene-propylene copolymerization polypropylene

An ethylene propylene copolymer polypropylene and ethylene propylene rubber technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of large measurement error, high purchase cost, complicated operation, etc., and achieve fast detection speed, wide detection range, The effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

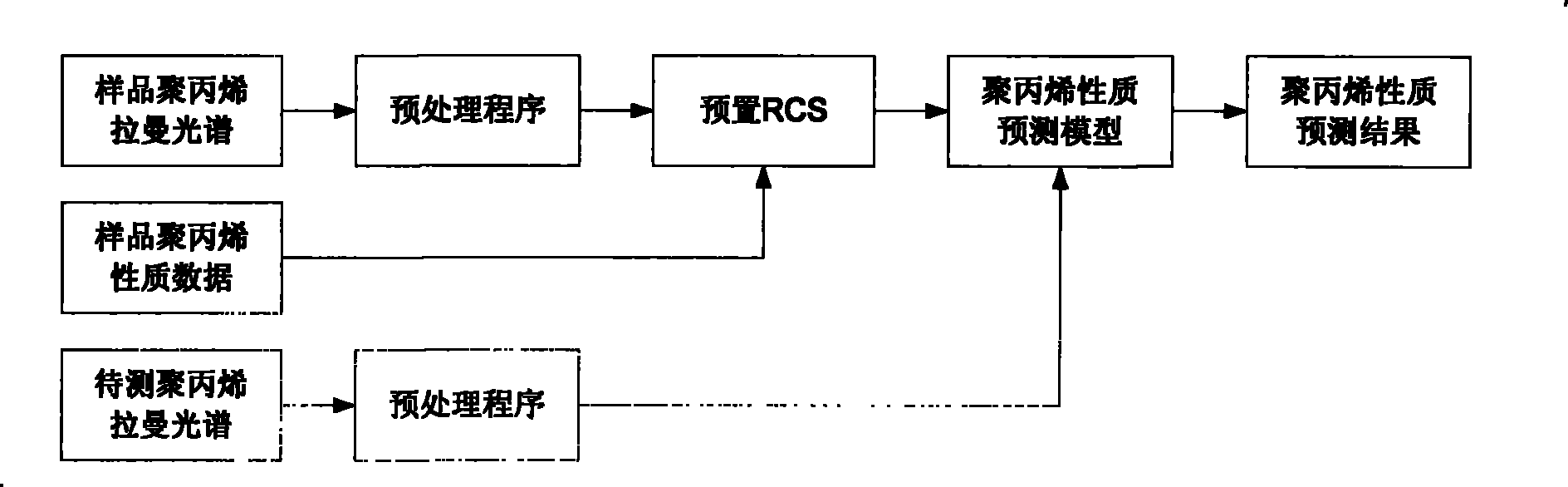

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The MultiRAM type Fourier Raman spectrometer produced by German Bruker Company is adopted, and the wavelength of the laser light source used in the spectrometer is 1064nm. Set the spectral scanning range of the spectrometer from 0 to 3600cm -1 , with a resolution of 1cm -1 . Through non-immersion measurement, the Raman spectra of several samples of ethylene-propylene copolymer polypropylene were detected, and the ethylene content and ethylene-propylene rubber content were predicted. The ethylene content and ethylene-propylene rubber content of the known samples are shown in Table 1:

[0033] Table 1 Properties of polypropylene samples

[0034] Sample serial number

MFR

Ethylene content

Ethylene Propylene Rubber Content

1

1.5

7.5

12.5

2

2.5

10.5

16.1

3

10.4

6.8

13.4

4

9.0

9.9

20.0

5

8.8

13.5

22.5

6

2...

Embodiment 2

[0058] The MultiRAM type Fourier Raman spectrometer produced by German Bruker Company is adopted, and the wavelength of the laser light source used in the spectrometer is 1064nm. Set the spectral scanning range of the spectrometer from 0 to 3600cm -1 , with a resolution of 10cm -1 . By non-immersion measurement, the Raman spectrum of the ethylene-propylene copolymer polypropylene sample is detected, and the ethylene content is predicted.

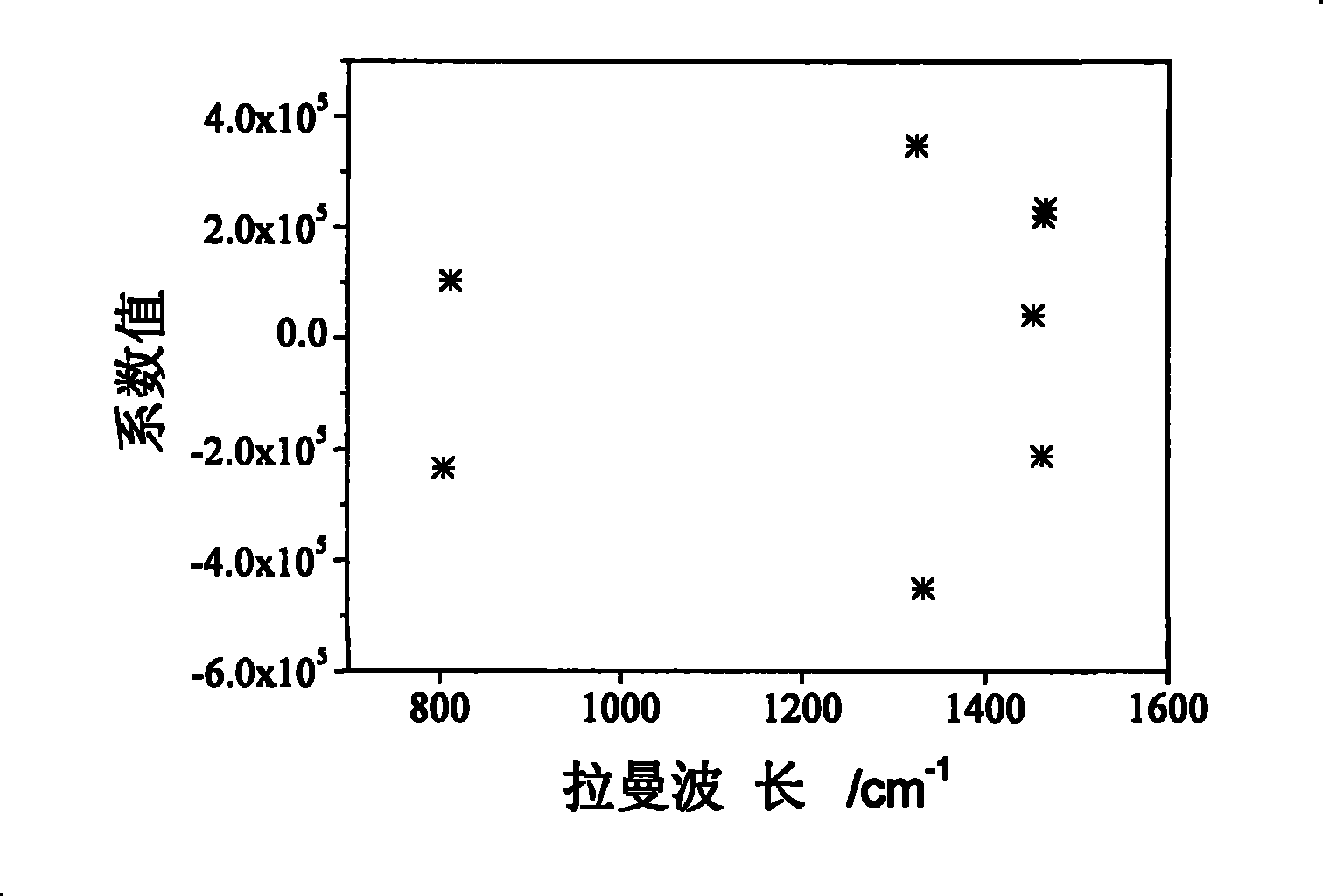

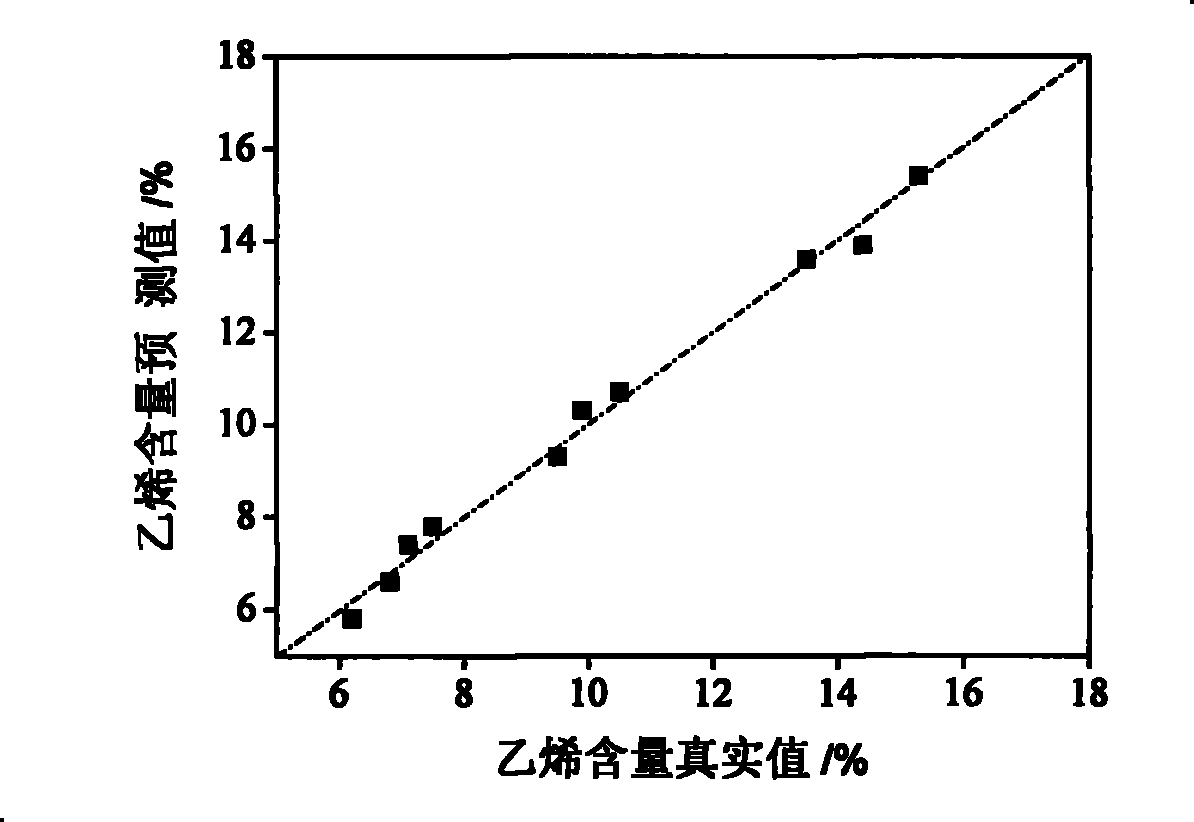

[0059] First, according to the Raman spectrum intensity set I corresponding to the preset characteristic wavenumber set RCS detected by the ethylene content RCS Ethylene content Y with polypropylene EC Carry out modeling by multiple linear regression, concrete process is as embodiment 1, obtains the prediction result of ethylene content in the ethylene-propylene copolymer polypropylene, as Figure 6 shown.

[0060] Then, the preset characteristic wavenumber set RCS is optimized, and the characteristic Raman wavenumber set corresponding ...

Embodiment 3

[0088] The MultiRAM type Fourier Raman spectrometer produced by German Bruker Company is adopted, and the wavelength of the laser light source used in the spectrometer is 1064nm. Set the spectral scanning range of the spectrometer from 0 to 3600cm -1 , with a resolution of 4cm -1 . Through non-immersion measurement, the Raman spectrum of the ethylene-propylene copolymer polypropylene sample is detected, and the ethylene content and ethylene-propylene rubber content are predicted.

[0089] Taking the prediction of ethylene-propylene rubber content as an example, the process is as follows:

[0090] First, the Raman spectrum intensity set I corresponding to the preset characteristic wavenumber set RCS detected according to the content of ethylene-propylene rubber RCS with known EPDM content Y R Modeling is carried out by multiple linear regression, the specific process is as in Example 1, and the prediction result of the ethylene-propylene rubber content is obtained, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com