Multifunctional in-situ electro-chemical measuring apparatus for tensile test

An in-situ electrochemistry and measurement device technology, applied in the field of electrochemistry, can solve problems such as differences, errors, and incomplete experimental data, and achieve the effects of complete data points, easy operation, and reliable experimental data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

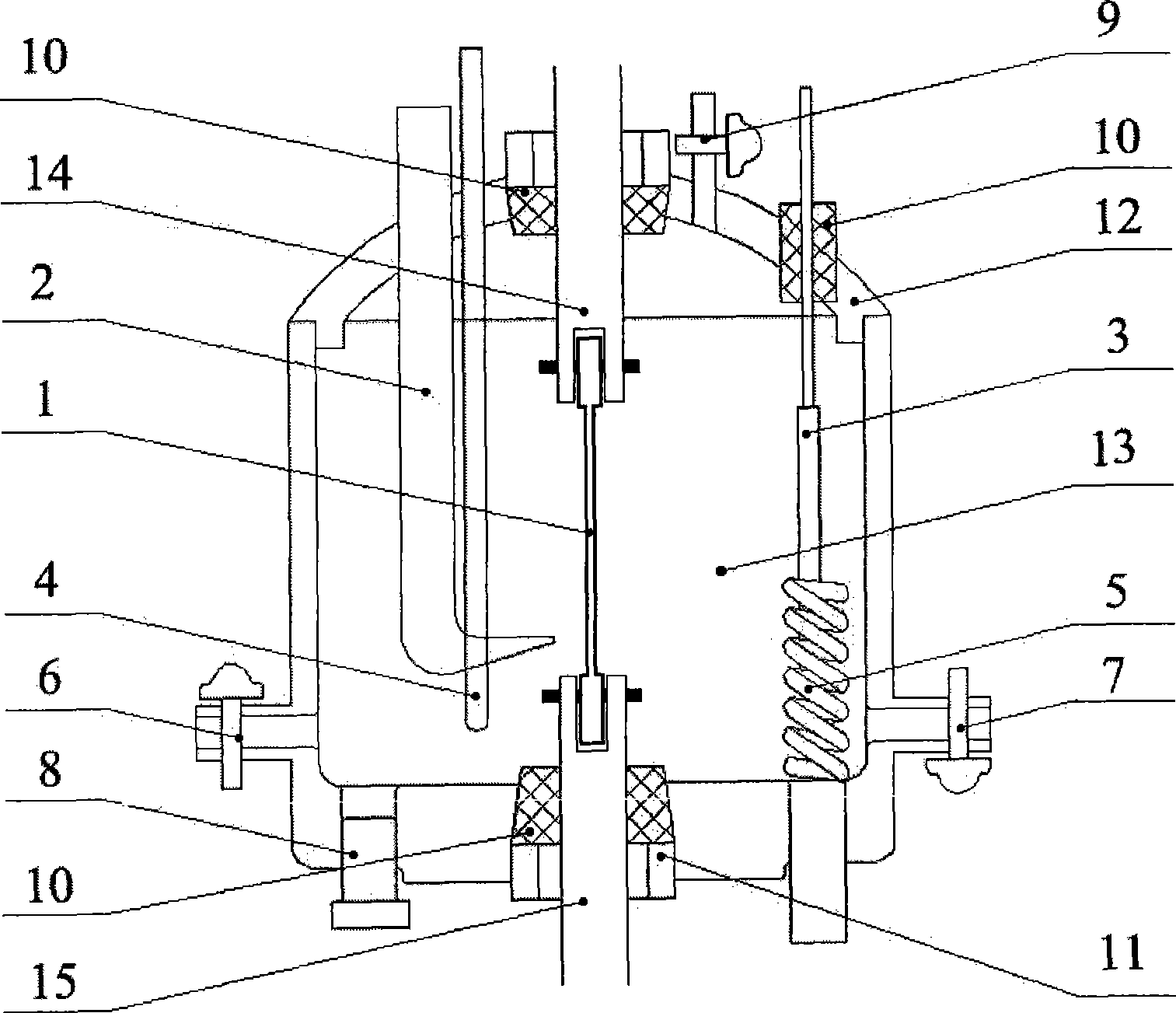

[0021] Example 1: Install the multifunctional in-situ electrochemical measuring device required for the tensile test to conduct the electrochemical test of the three-electrode system (simulation of a specific gas environment in the solution)

[0022] 1. Load the multifunctional in-situ electrochemical measuring device into the stretching machine, in which the chamber 13 falls on the lower chuck 15.

[0023] 2. Seal the tensile specimen 1 with the wire welded and the upper and lower chucks 14, 15 with 704 silica gel, leaving an area of the predetermined value for the test.

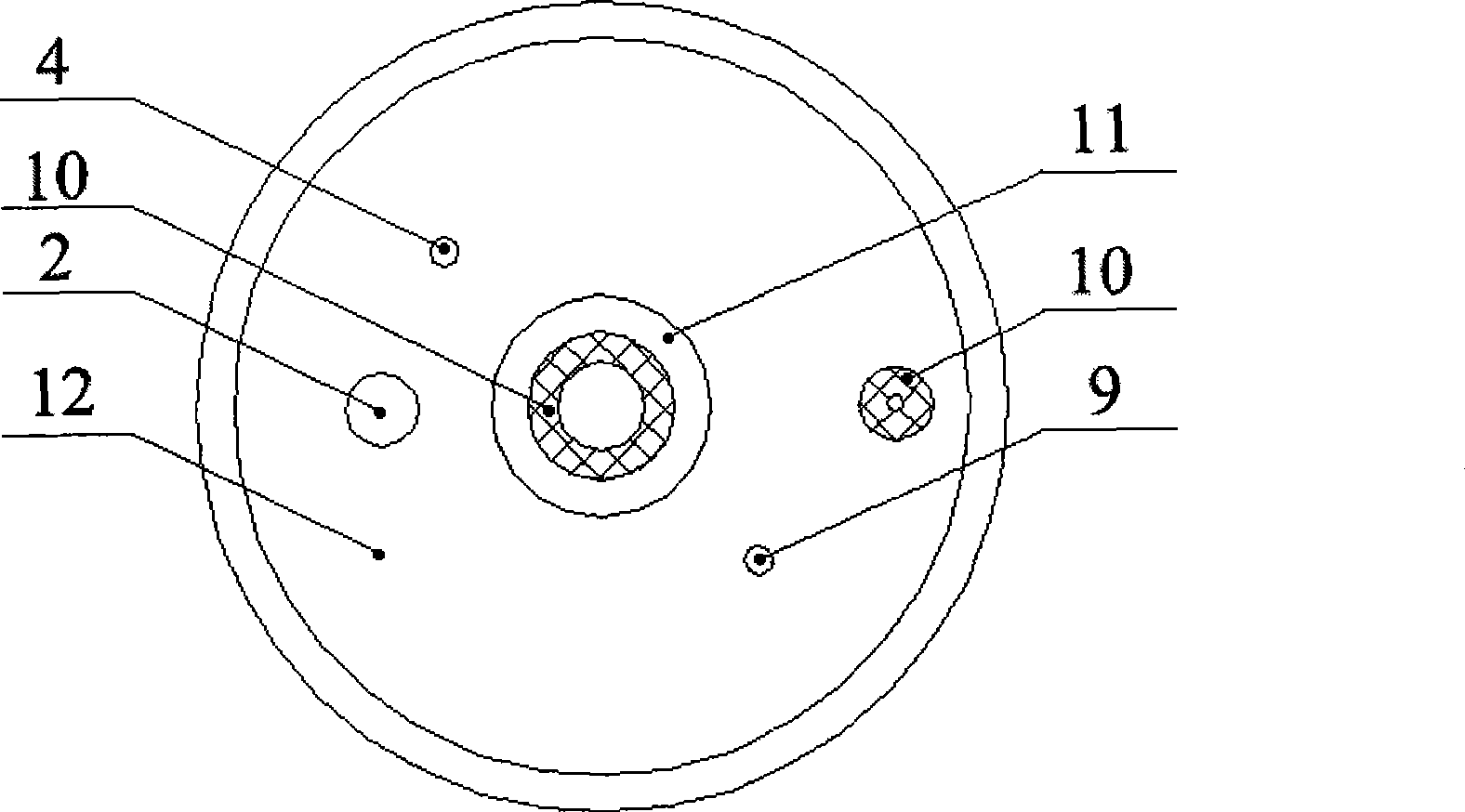

[0024] 3. Install the salt bridge 2, the thermocouple 4, and the rubber plug 10 into the top cover 12, and insert the metal platinum auxiliary electrode 3 into the rubber plug 10.

[0025] 4. Put the rubber plug 10 into the cavity 13, and pass the tensile sample 1 through the rubber plug in the cavity 13 and the top cover 12. The rotating top cover 12 and the chamber 13 are closed,

[0026] 5. Install the hea...

Embodiment 2

[0030] Example 2: Install the multifunctional in-situ electrochemical measuring device required for the tensile test to conduct the electrochemical test of the three-electrode system (simulation of the alternate dry and wet environment)

[0031] 1. Load the multifunctional in-situ electrochemical measuring device into the stretching machine, in which the chamber 13 falls on the lower chuck 15.

[0032] 2. Seal the tensile specimen 1 with the wire welded and the upper and lower chucks 14, 15 with 704 silica gel, leaving an area of the predetermined value for the test.

[0033] 3. Install the salt bridge 2, the thermocouple 4, and the rubber plug 10 into the top cover 12, and insert the metal platinum auxiliary electrode 3 into the rubber plug 10.

[0034] 4. Put the rubber plug 10 into the cavity 13, and pass the tensile sample 1 through the rubber plug in the cavity 13 and the top cover 12. The rotating top cover 12 and the chamber 13 are closed,

[0035] 5. Close the air inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com