Heat conduction mechanism for temperature compensation test device of weighting transducer

A technology of weighing sensor and temperature compensation, applied in the direction of weighing temperature compensation device, weighing equipment testing/calibration, etc. The effect of holding time, saving energy and accelerating heat balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

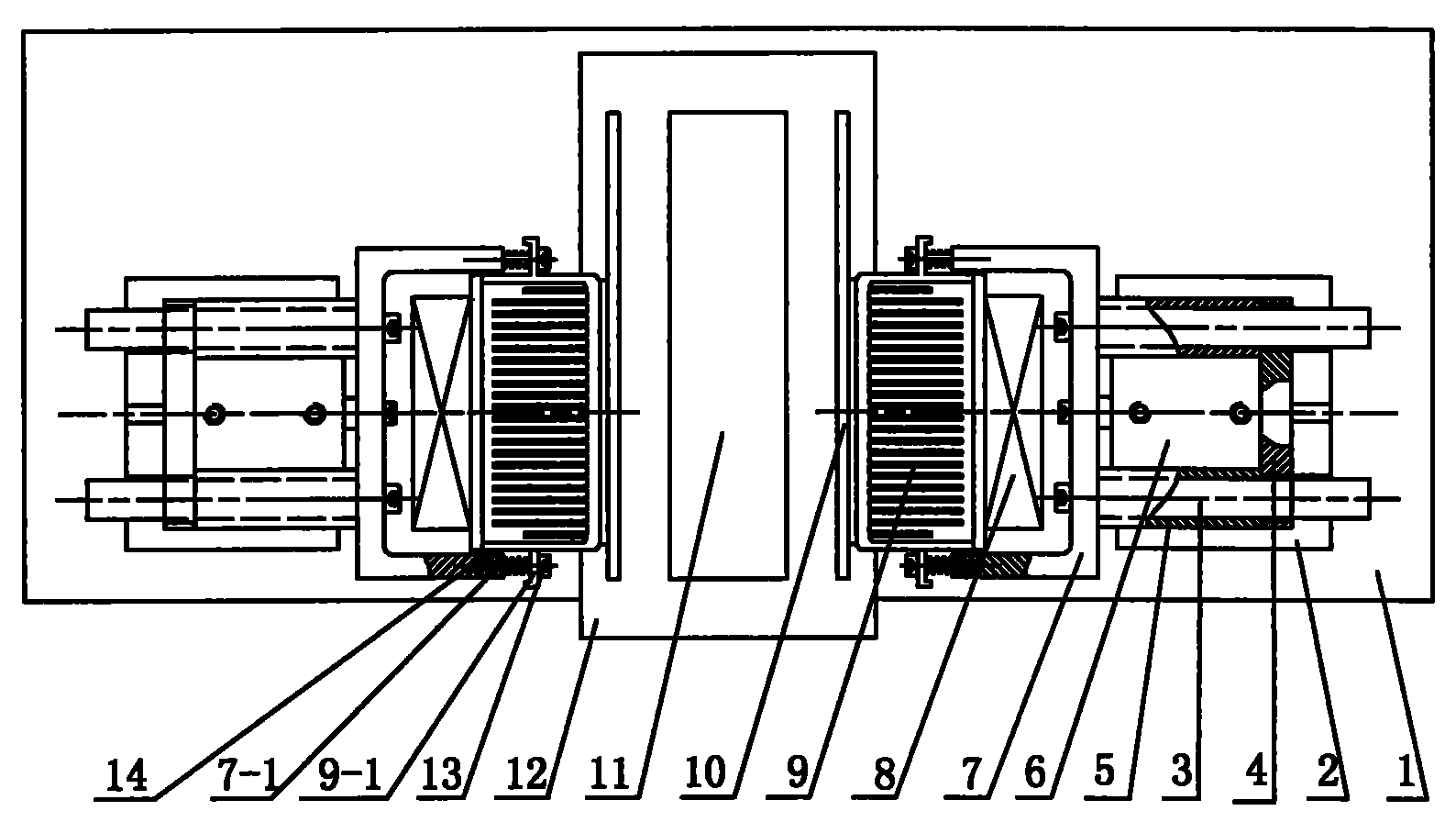

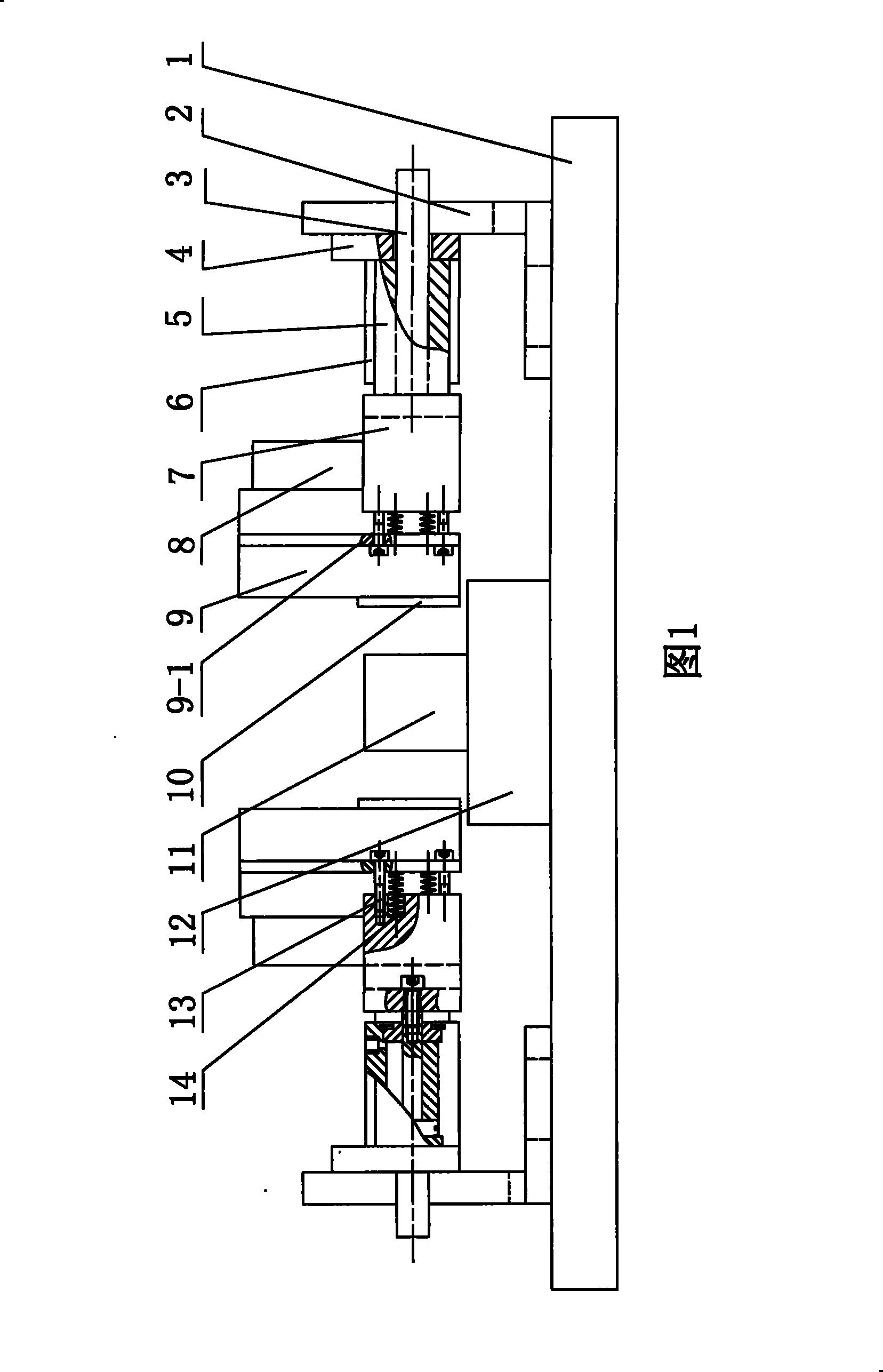

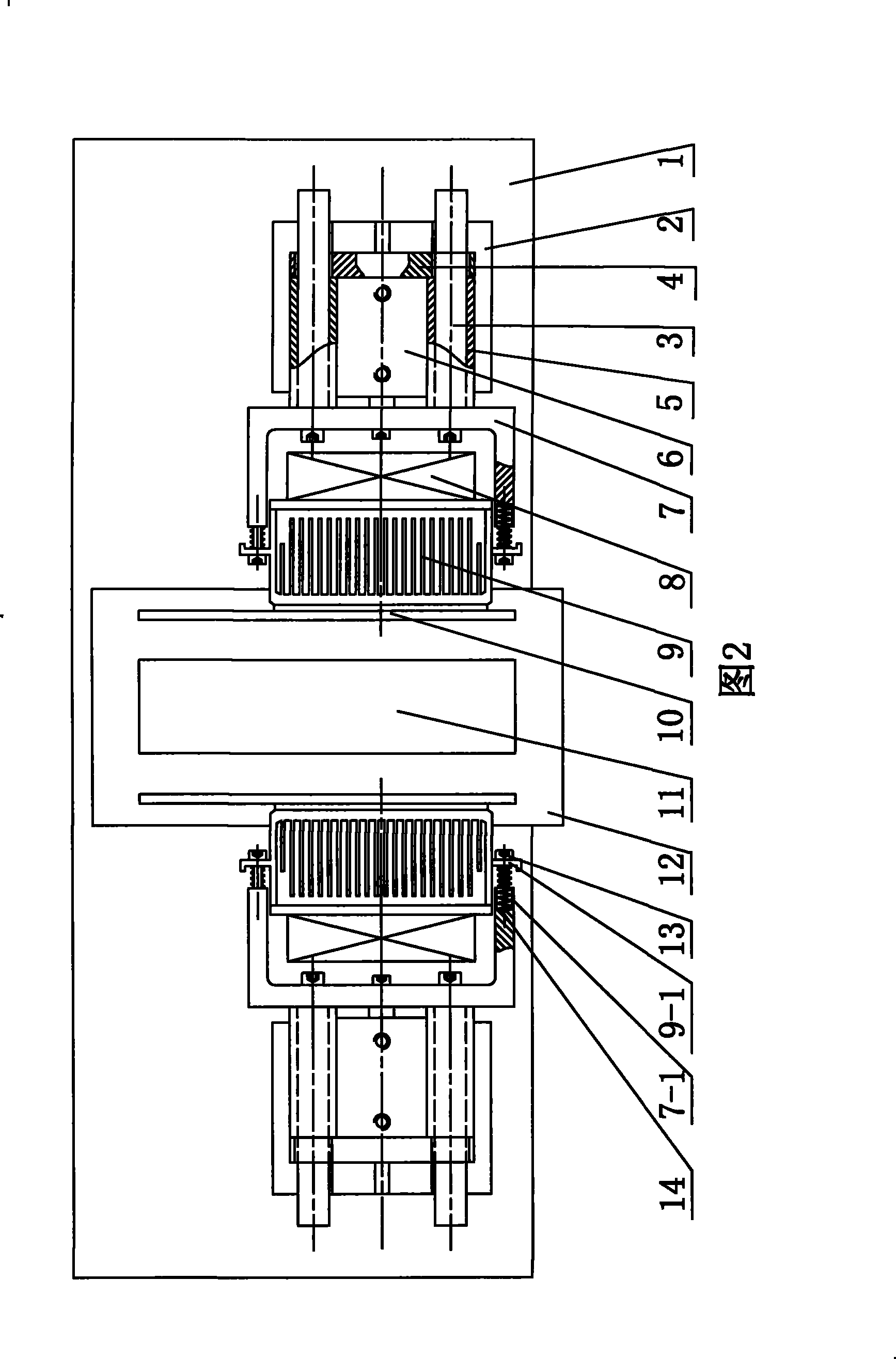

[0012] As shown in Figures 1 to 2, the heat conduction mechanism of the load cell temperature compensation test device of the present invention is composed of two groups of conduction clamping mechanisms that are symmetrically installed on the test platform 1 and have the same structure. The conduction clamping mechanism of the present invention It includes a base 2 , a conduction plate 10 , a heat sink 9 , a fan 8 , a cylinder 6 , a bracket 7 and a spring 14 , and the cylinder 6 is installed on the base 2 . In order to adjust the position of the cylinder 6 and meet load cells of different sizes, the rear end of the cylinder 6 is installed on the cylinder mounting plate 4, and the base 2 is L-shaped, as shown in Figures 3 and 4, the vertical position of the base 2 of the present invention There are vertical grooves 2-1 on the plate, and two waist-shaped holes 2-2 on the bottom plate. The connecting bolts are set in the vertical grooves 2-1 of the base 2 and screwed into the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com