Slewing drum shaped multi-pipe drying mechanism and its use in drying water-containing lignite

A drying device and rotary drum technology, applied in the direction of drying gas arrangement, drying solid materials, non-progressive dryers, etc., can solve the problems of not being suitable for drying lignite rich in water, shorten heating time, increase heat transfer coefficient, easy flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Model selection and main parameters of lignite drying equipment with an annual output of 250,000 tons of lignite designed by the present invention.

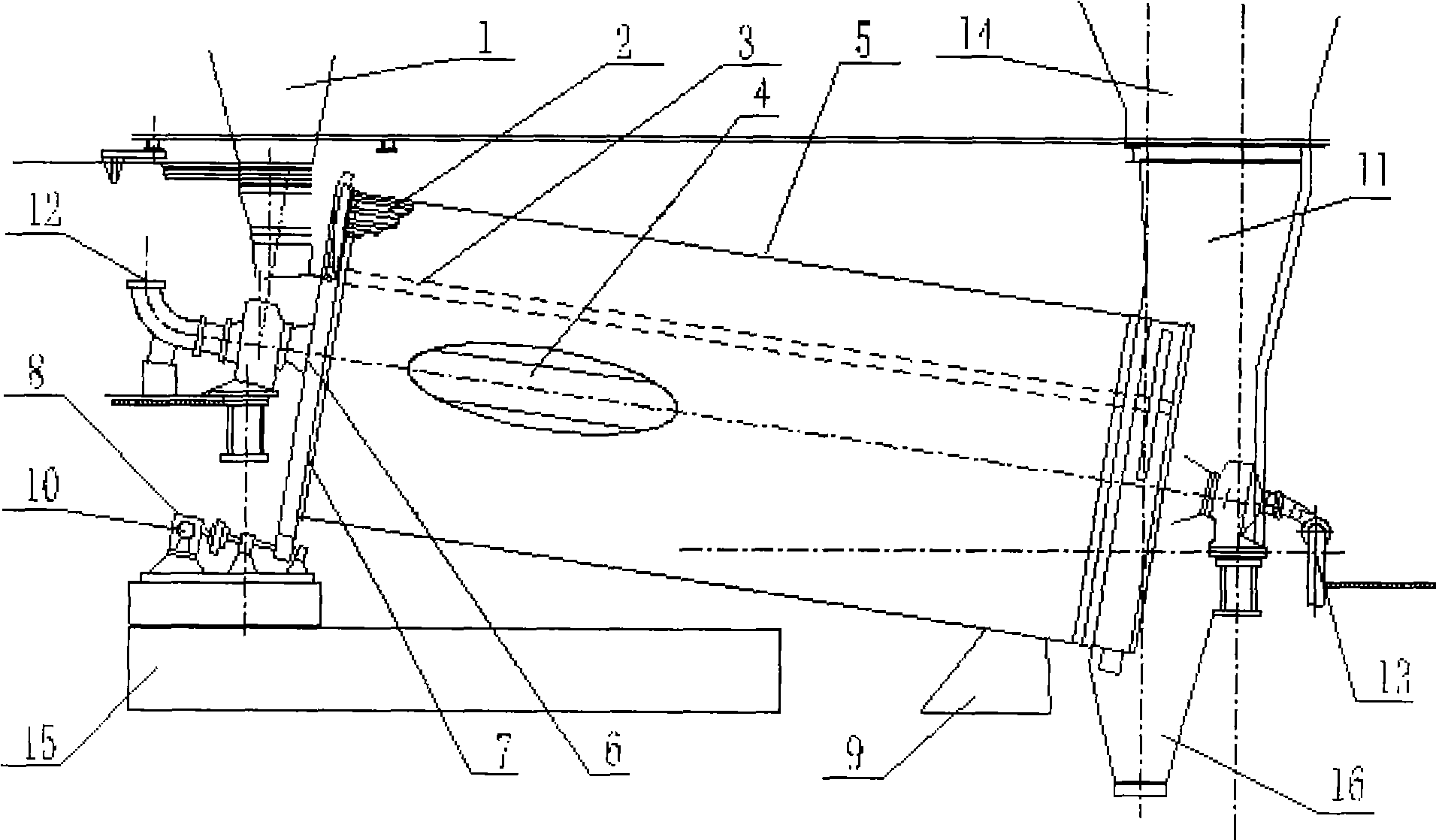

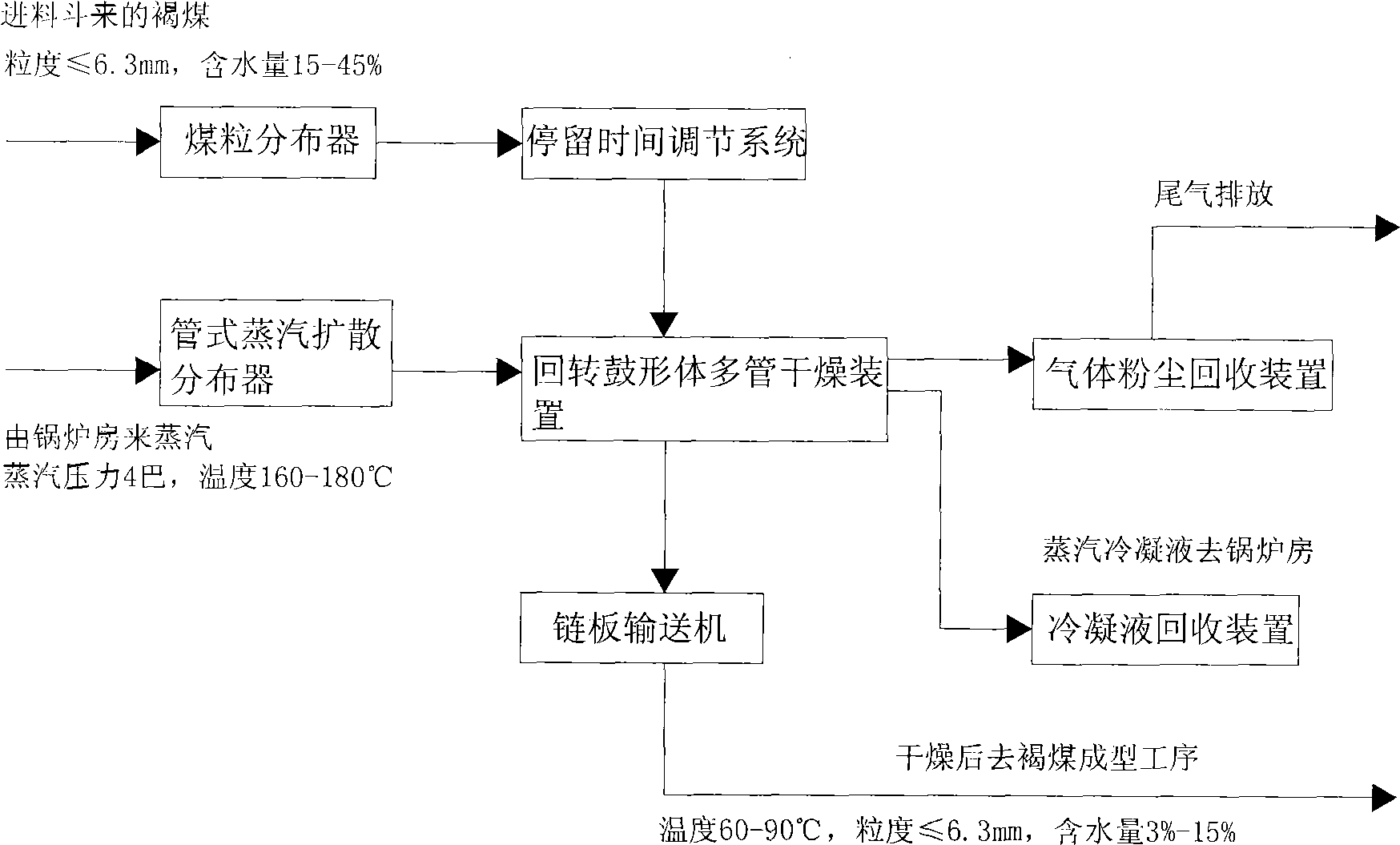

[0034] Description of the working principle (see figure 1 , 2 ):

[0035] 1. The lignite (or other water-rich materials) with a water content of 15wt% to 50wt% and a coal particle size of <6.3mm (or other water-rich materials) can be dried to a product with a water content of ≤8% (or Dry to the moisture content of coal particles ≤ 3% as needed). The drying heating medium adopts low-pressure steam, and the indirect drying method is completed.

[0036] 2. Feeding particle size control. The lignite and coal particles with a water content of 35wt% at room temperature from the boundary area are 20-50mm. After entering the reversible hammer crusher, they are hit by the high-speed rotating hammer to the counterattack plate, and the coal particles are crushed to ≤6.3mm. The water content is 35%, and it is used as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com