Pump impeller

A pump impeller and vane pump technology, which is applied in the direction of pumps, pump control, pump components, etc., can solve the problems of vane pump assembly difficulties, pump impeller manufacturing difficulties, etc., reduce the risk of cavitation, simple assembly, and increase the delivery volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

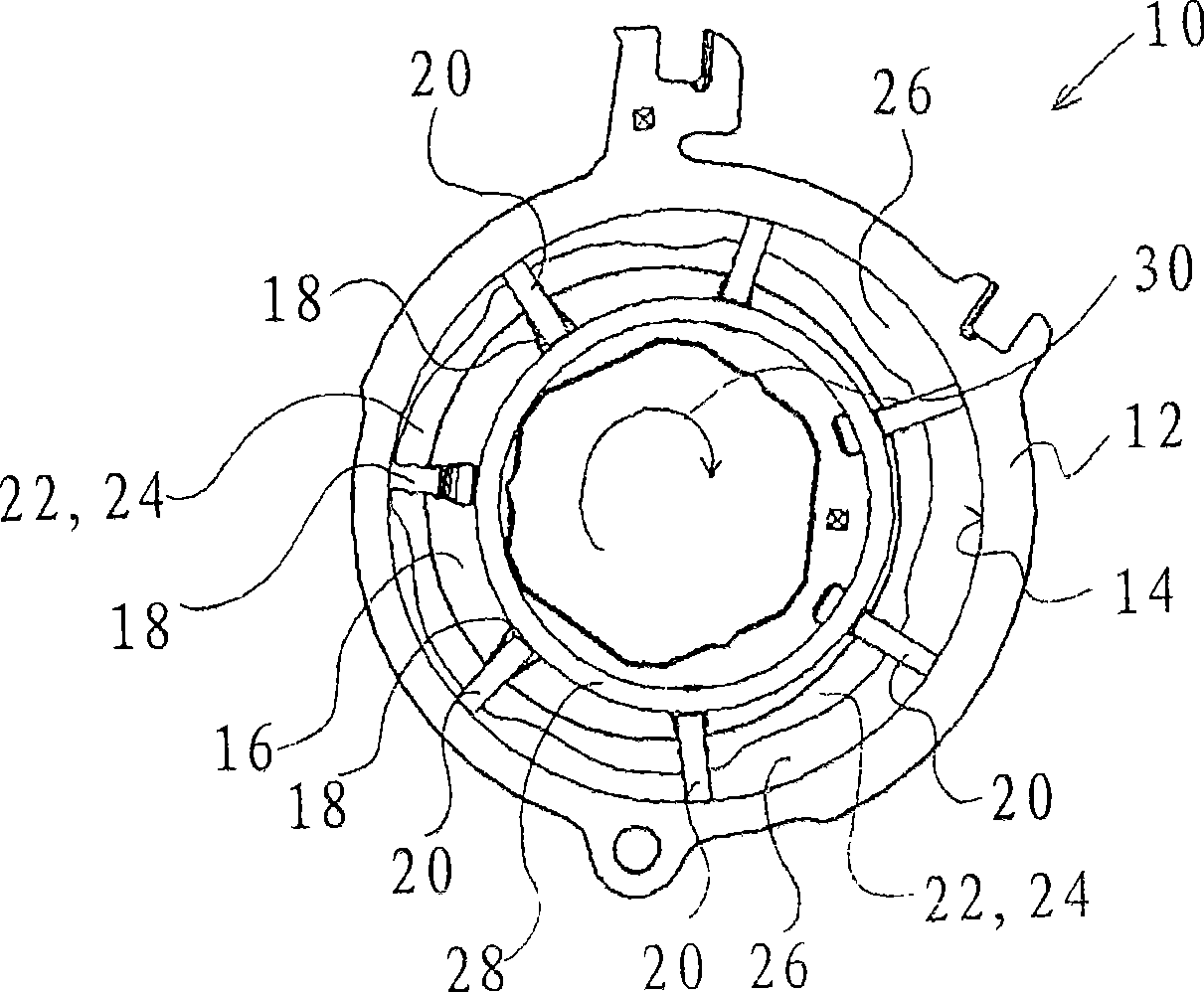

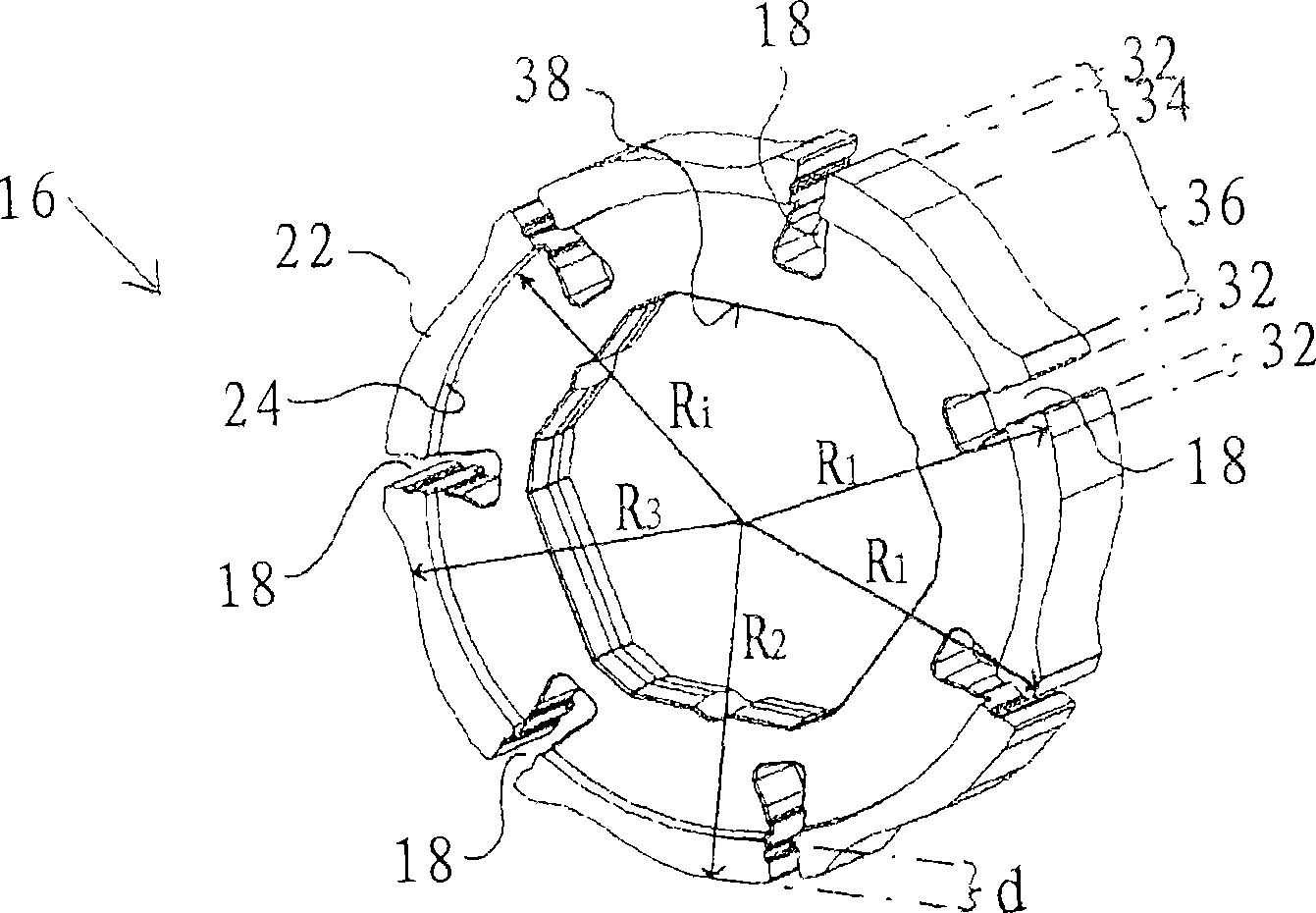

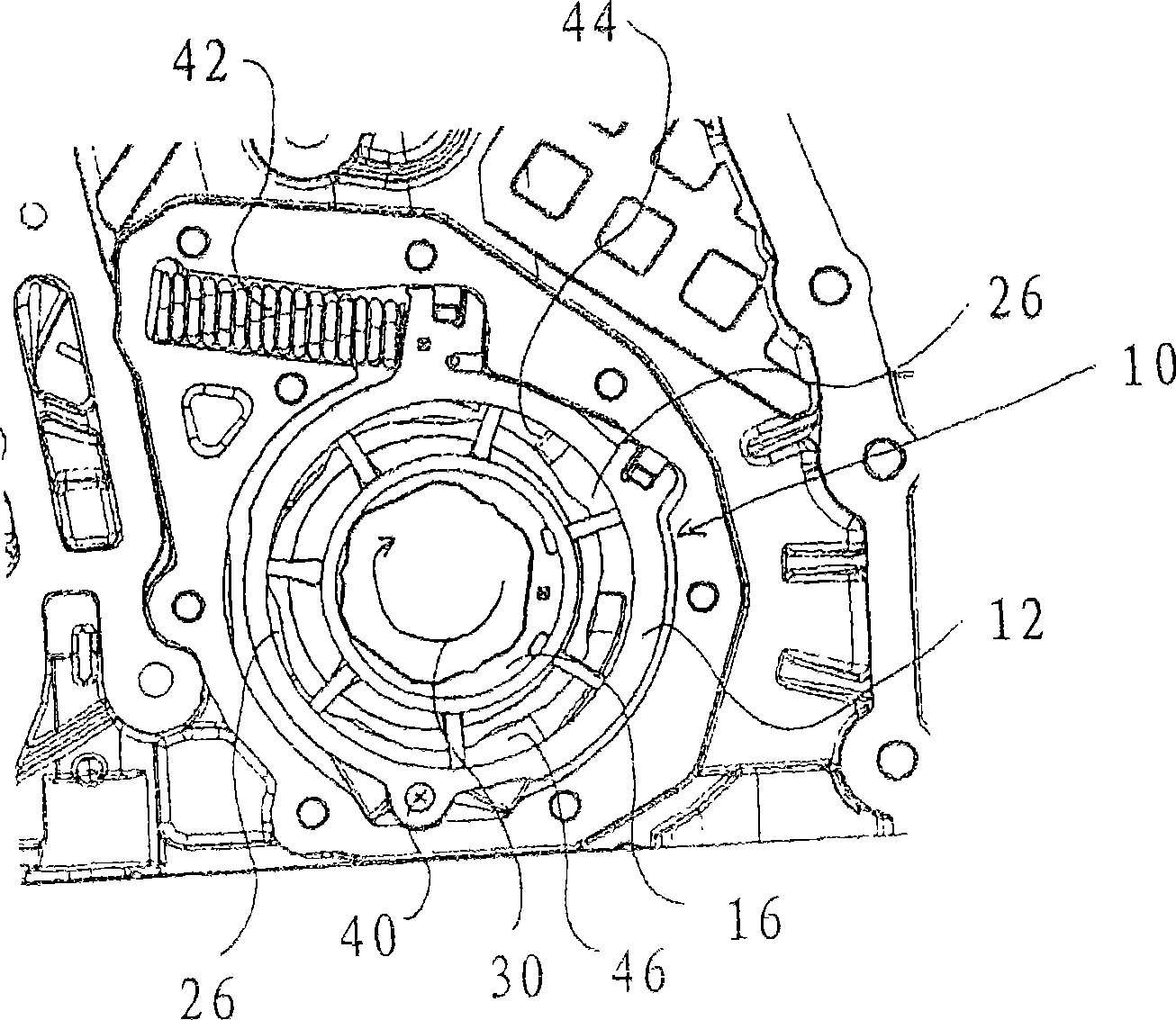

[0021] figure 1 The illustrated vane pump 10 has a housing ring 12 with a circular inner contour 14 . The pump impeller 16 is mounted eccentrically in the housing ring 12 relative to the housing ring. The pump wheel 16 has a plurality of vane slots 18, each of which has a pump vane 20 installed therein. Formed between two adjacent vane grooves 18 is a chamber wall 22 which has an axially protruding land 24 with respect to the other pump wheel 16 . The chamber wall 22 , the respective pump blades 20 belonging to the chamber wall and the inner contour 14 of the housing ring 12 form a delivery chamber 26 .

[0022] An elastic positioning ring 28 is arranged radially inside the pump vane 20, which is closely attached to the radially inward surface of the pump vane 20, so as to squeeze the pump vane 20 radially outward, thereby pumping the pump even at low speeds. The blades 20 also bear against the inner contour 14 of the casing ring 12 . The movement of the positioning ring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com