Concrete well wall module

A wall and well wall technology, which is applied in the field of concrete well wall modules with convex grooves and concrete well wall modules, can solve the problems of pores or hollows, long construction period, and increased costs, and reduce the waterproofing process , enhance the shear performance, and the wall is firm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention is described in detail as follows.

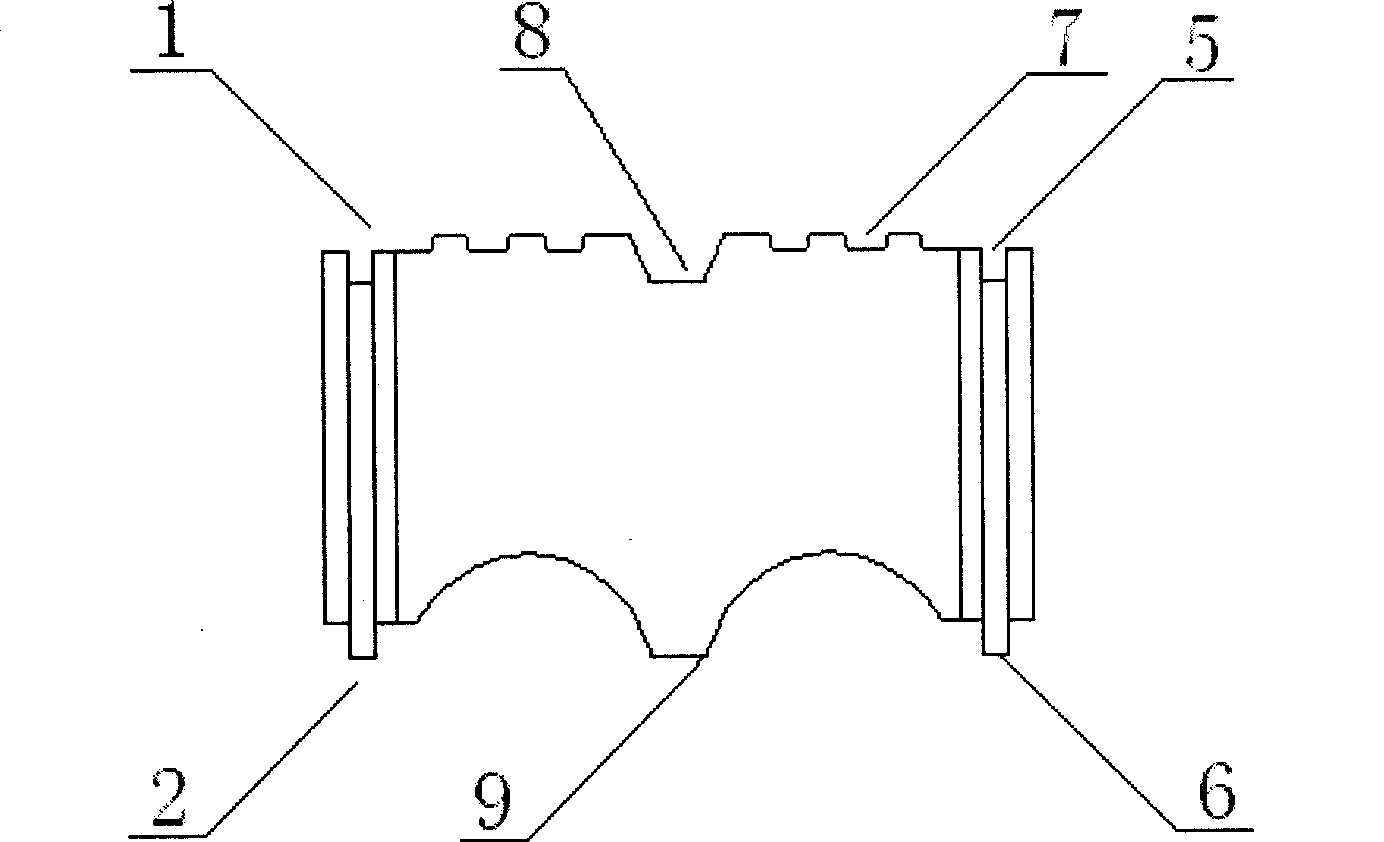

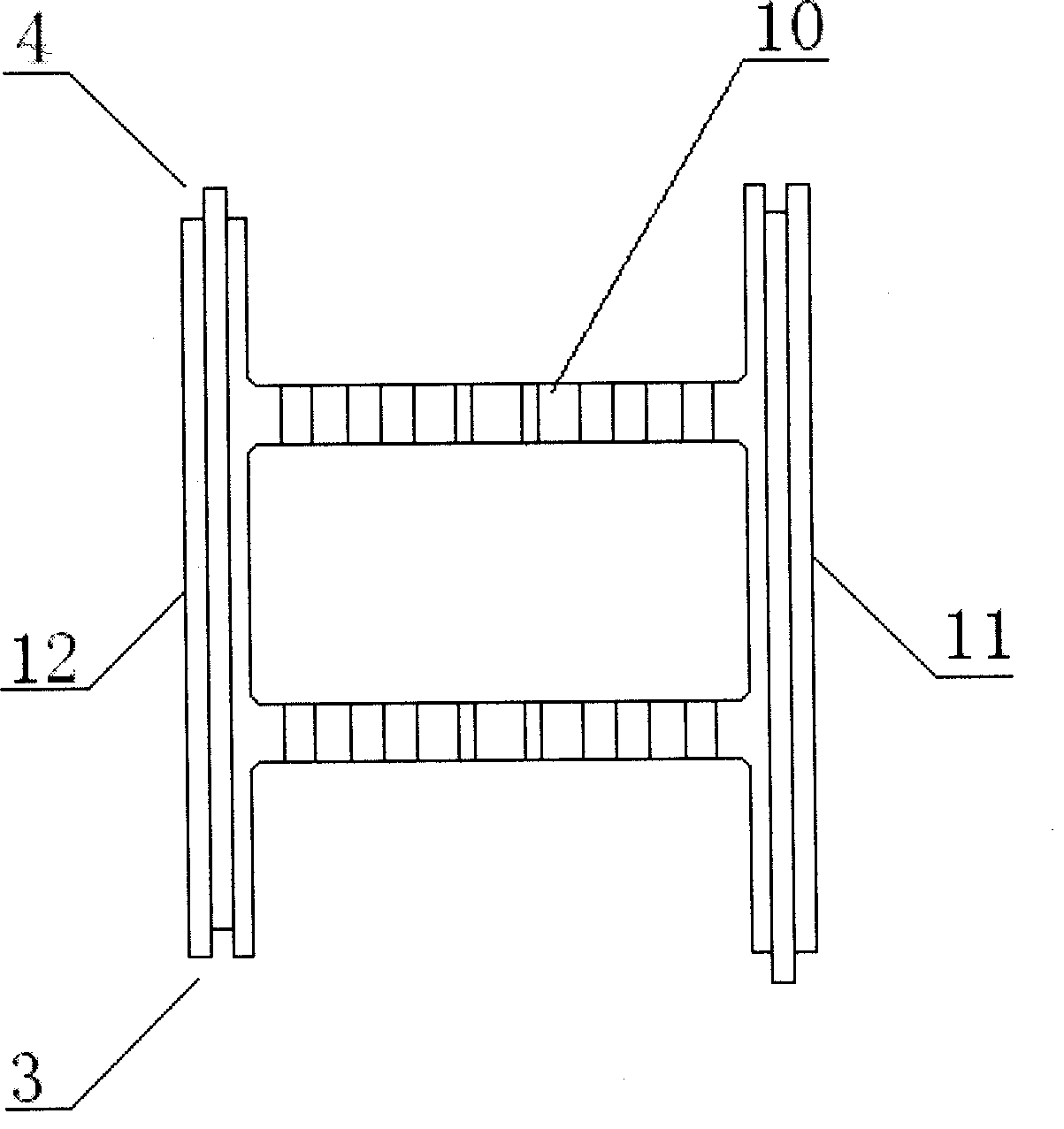

[0023] figure 1 is the front view of the concrete shaft wall module of the present invention; figure 2 It is a top view of the concrete shaft wall module of the present invention.

[0024] As shown in the figure, the concrete shaft wall module of the present invention includes a left frame 12, a right frame 11 and a connecting edge 10, and the upper reference plane 1, the lower reference plane 2, and the front reference plane of the left frame 12 and the right frame 11 3 and the rear reference plane 4 are respectively provided with grooves 5 and ribs 6 correspondingly, an intermediate groove 8 is provided in the middle of the upper reference plane 1 of the connecting rib 10, and an intermediate convex is provided in the middle of the lower reference plane 2. The rib 9; the middle rib 9 is connected with the left frame 12 and the right frame 11 through an arc. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com