Micropore preservative film for garden stuff

A fresh-keeping film and microporous technology, which is used in the protection of fruits/vegetables, applications, household appliances, etc. with a protective layer, can solve the problems of not being able to play a good role in fresh-keeping and no two-way adjustment, and achieve the performance and structure of the film. Stable, good opening, humidity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Low-density polyethylene resin 100 kg

[0051] Ethylene-vinyl acetate resin 20 kg

[0052] Linear Polyethylene Resin 10kg

[0053] Superfine Calcium Carbonate 13kg

[0054] Superfine Medical Stone 8kg

[0055] Tween 80 1 kg

[0056] Anti-fogging agent: glycerol monooleate 1.0 kg

[0057] Antistatic agent SWJU-1 1.5 kg

[0058] 1076 antioxidant 0.5 kg

[0059] Polyethylene wax 0.6 kg

[0060] The ingredients are weighed according to the above proportions, after being mixed by a plastic particle mixer, blown by a Φ45-Φ65mm single-screw extrusion blow molding machine, and stretched vertically and horizontally to form a film. The screw speed of blow molding is 45r / min, and the temperature of the four stages is: 100°C, 145°C, 165°C, 180°C. The pore diameter of the prepared film is 0.1-3um, and the porosity is 40%-55%.

[0061] 1. The production of masterbatch, which is filled with high-speed twin-screw exhaust type gripping extrusion granulation unit, the production...

Embodiment 2

[0066] in

[0067] Low-density polyethylene resin 100 kg

[0068] Ethylene-vinyl acetate resin 10 kg

[0069] Linear polyethylene resin 8 kg

[0070] Superfine Calcium Carbonate 5kg

[0071] Superfine Medical Stone 5kg

[0072] Tween 80 1 kg

[0073] Anti-fog agent 0.5 kg

[0074] Antistatic agent SWJU-1 1 kg

[0075]1076 antioxidant 0.3 kg

[0076] Polyethylene wax 0.5 kg

[0077] The ingredients are weighed according to the above proportions, after being mixed by a plastic particle mixer, blown by a Φ45-Φ65mm single-screw extrusion blow molding machine, and stretched vertically and horizontally to form a film. The screw speed of blow molding is 45r / min, and the temperature of the four stages is: 100°C, 145°C, 165°C, 180°C. The pore diameter of the prepared film is 0.1-3um, and the porosity is 40%-55%.

Embodiment 3

[0079] Low-density polyethylene resin 100 kg

[0080] Ethylene-vinyl acetate resin 25 kg

[0081] Linear Polyethylene Resin 15kg

[0082] Superfine Calcium Carbonate 18kg

[0083] Superfine Medical Stone 15kg

[0084] Tween 80 5 kg

[0085] Anti-fog agent 1.5kg

[0086] Antistatic agent SWJU-1 3 kg

[0087] 1076 antioxidant 0.6 kg

[0088] Polyethylene wax 3 kg

[0089] The ingredients are weighed according to the above proportions, after being mixed by a plastic particle mixer, blown by a Φ45-Φ65mm single-screw extrusion blow molding machine, and stretched vertically and horizontally to form a film. The screw speed of blow molding is 45r / min, and the temperature of the four stages is: 100°C, 145°C, 165°C, 180°C. The pore diameter of the prepared film is 0.1-3um, and the porosity is 40%-55%.

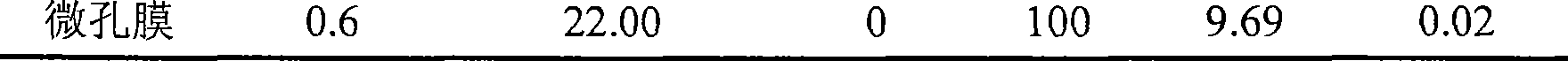

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com