Equipment for preparing mixed crude sand of sand core and method for preparing mixed crude sand

A sand core and equipment technology, applied in the field of raw sand production equipment and preparation, can solve the problems of increased cleaning difficulty, large fluctuations in the quality of the inner cavity, and the performance of regenerated sand is not as good as that of new sand, so as to reduce the workload and cleaning difficulty, reduce the cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

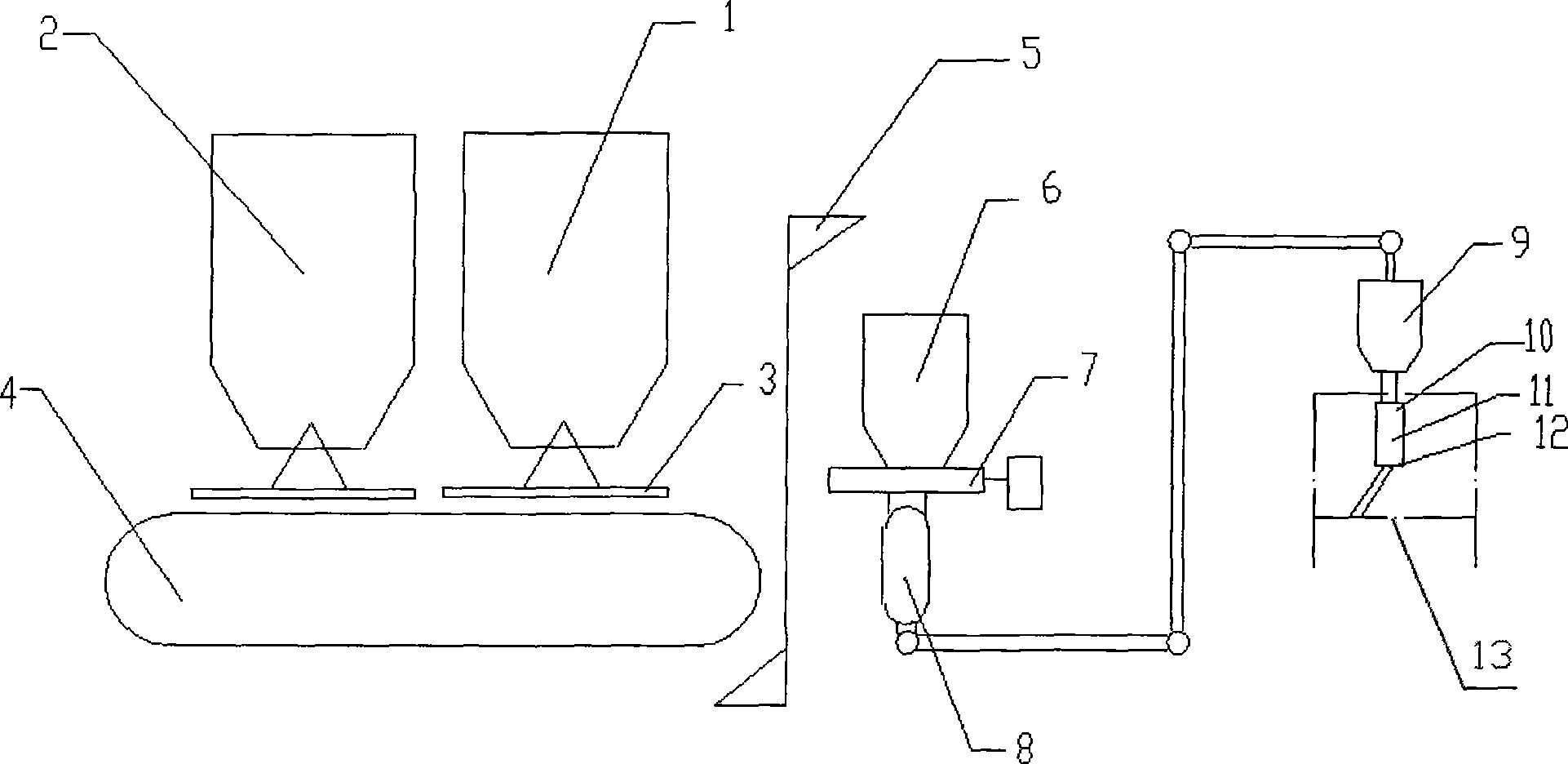

[0016] Such as figure 1 As shown, the present invention comprises a reclaimed sand storage bucket 1 and a new sand storage bucket 2 arranged side by side, openings at the lower ends of the regenerated sand storage bucket 1 and the new sand storage bucket 2, and are connected with a disc feeder 3, and the disc feeder A belt conveyor 4 is provided below the belt conveyor 4, and the bucket elevator 5 is adjacent to the side of the belt conveyor 4. The output end of the bucket elevator 5 is provided with a sand bucket 6, and a disc valve 7 is provided at the lower opening of the sand bucket 6. A sand conveyor 8 is connected to the lower end of the sand bucket 6, and the sand conveyor 8 is connected to a sand mixer 13. The sand mixer 13 includes a daily consumption bucket 9, an upper disc valve 10, a sand quantitative bucket 11, and a lower disc valve 12 arranged vertically from top to bottom.

[0017] When preparing the mixed raw sand, open the disc feeder under the regenerated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com