Upper straight-down rotating dry-type circulating fluidized bed desulfurization reactor

A circulating fluidized bed and reactor technology, applied in the field of flue gas purification, can solve the problems of easy formation of particles on the wall, low work efficiency, etc., to facilitate overall layout and operation and maintenance, increase residence time, and adapt sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

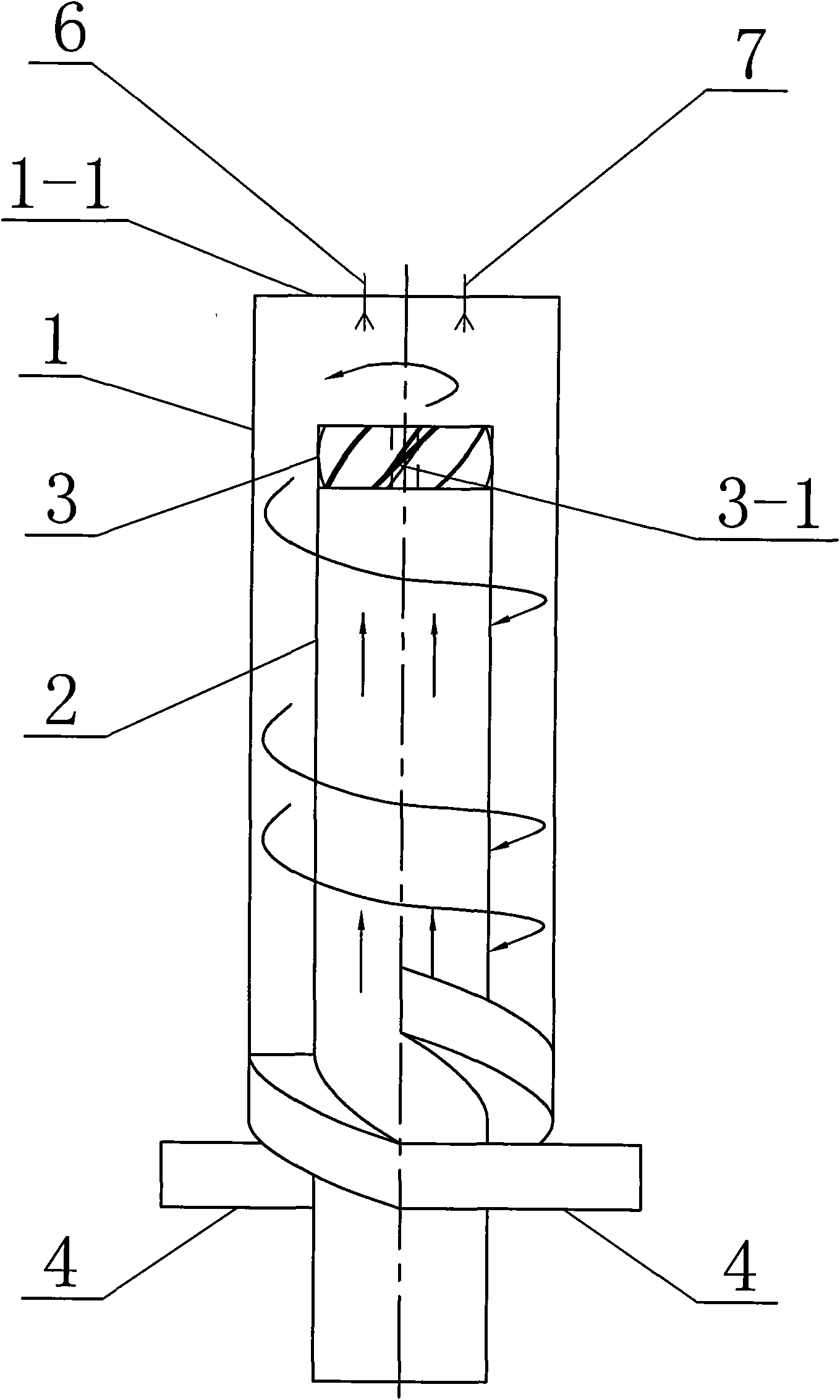

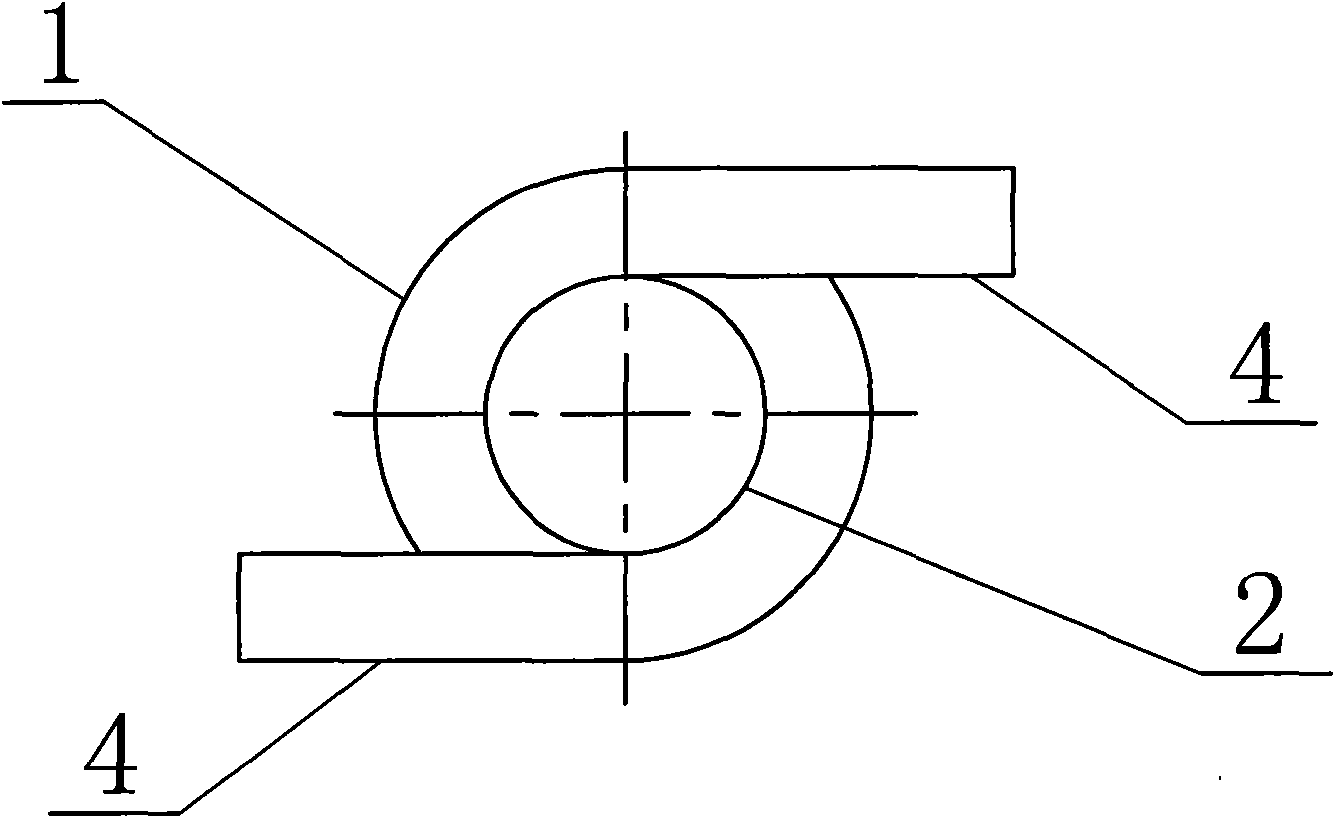

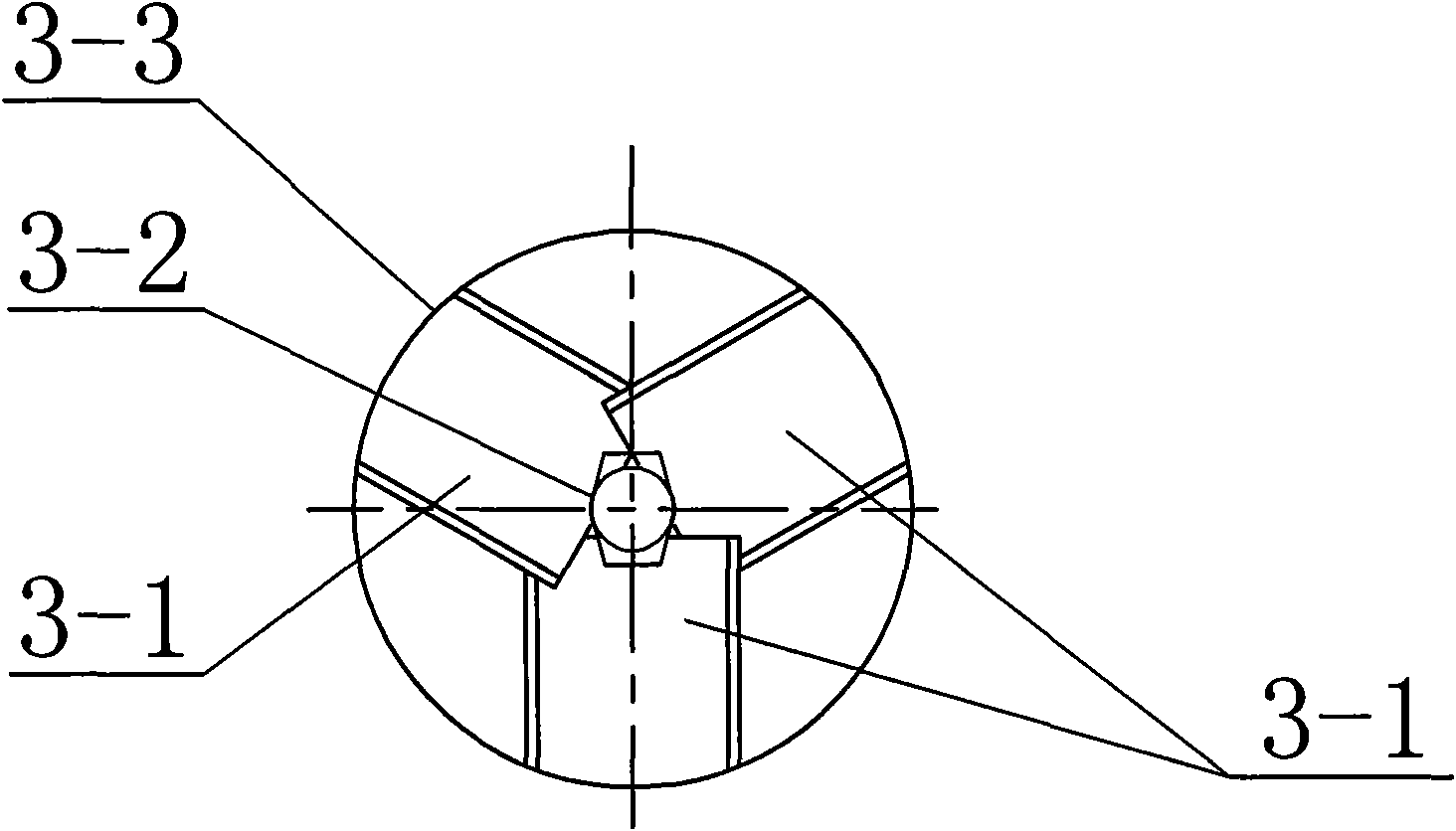

[0007] Specific implementation mode one: as Figure 1~4 As shown, the upper straight-down spin-dry circulating fluidized bed desulfurization reactor described in this embodiment includes an outer cylinder 1 and an inner cylinder 2, the upper end of the outer cylinder 1 is provided with an upper end cover 1-1, and the inner cylinder 1 The cylinder 2 is a cylindrical straight cylinder; the desulfurization reactor also includes a cyclone 3 and one to four tangential swirl smoke exhaust pipes 4, and the cyclone 3 is composed of three to twenty swirl plates 3-1 , a central axis 3-2 and a housing 3-3, the inner cylinder 2 is arranged in the outer cylinder 1 and the lower end of the inner cylinder 2 is located below the outer cylinder 1, and the cyclone 3 is arranged at the upper end of the inner cylinder 2; One to four tangential swirl smoke exhaust pipes 4 are located below the outer cylinder 1, and one to four tangential swirl smoke exhaust pipes 4 are evenly arranged on the outer...

specific Embodiment approach 2

[0008] Specific implementation mode two: as image 3 and Figure 4 As shown, the number of swirl plates 3-1 in this embodiment is four to eighteen. With such setting, the flue gas flow rate and flow rate entering the secondary cyclone reactor can be changed. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: as image 3 and Figure 4 As shown, the number of swirl plates 3-1 in this embodiment is six to sixteen. With such setting, the flue gas flow rate and flow rate entering the secondary cyclone reactor can be changed. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com