Drilling hole stress sensor and drilling hole stress monitoring method thereof

A stress sensor and stress monitoring technology, used in geological safety monitoring and geotechnical fields, can solve problems such as inconvenience in geotechnical and geological safety evaluation, and inability to obtain stress at different depths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

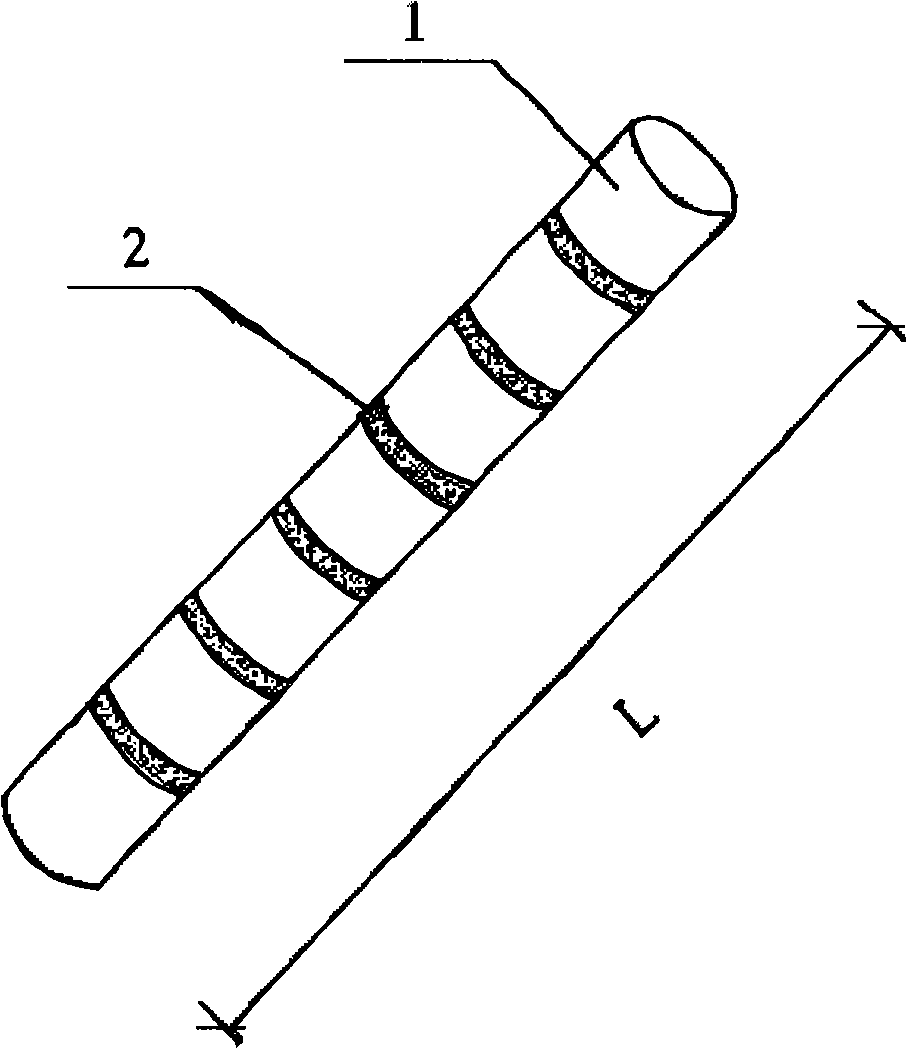

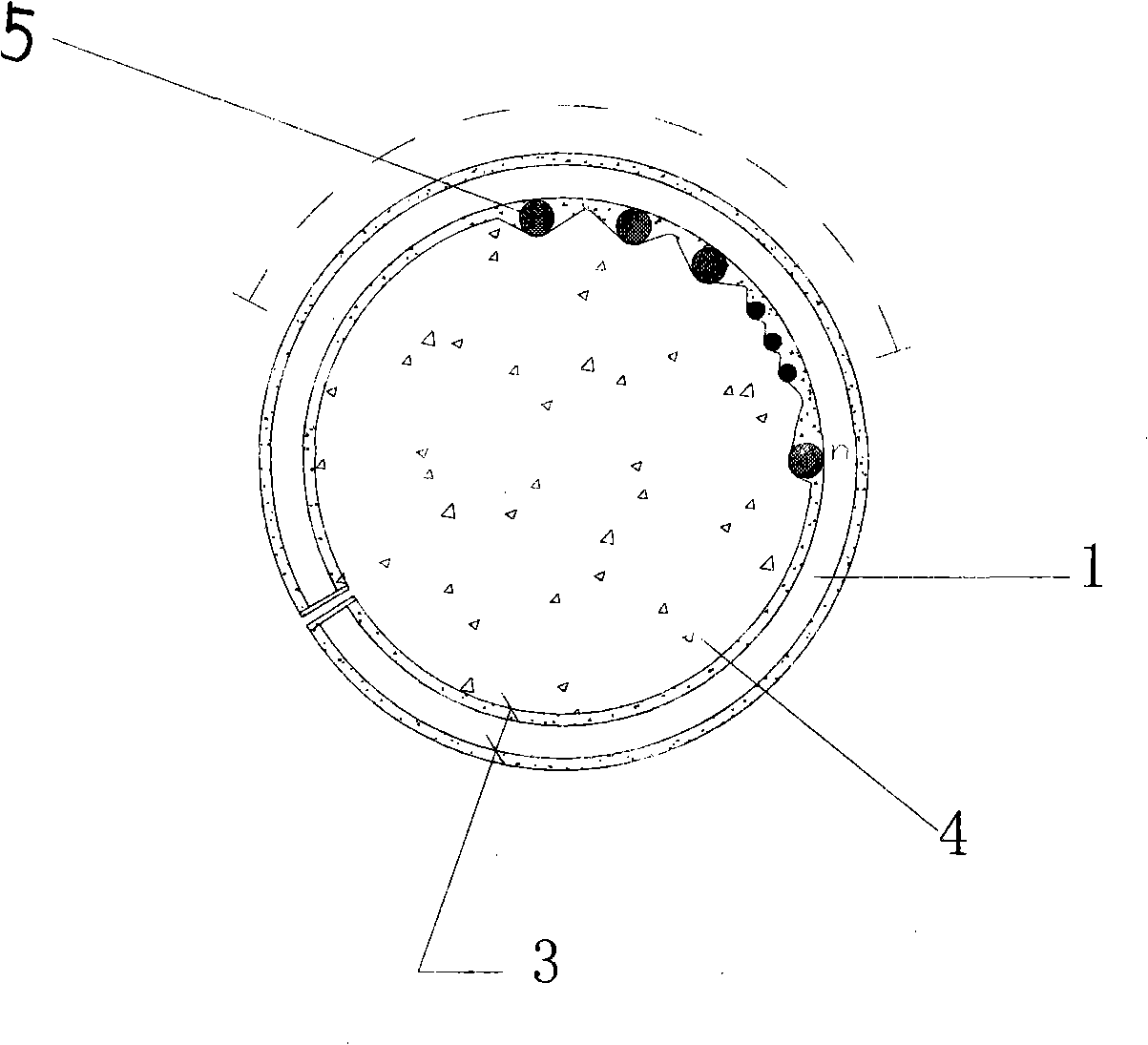

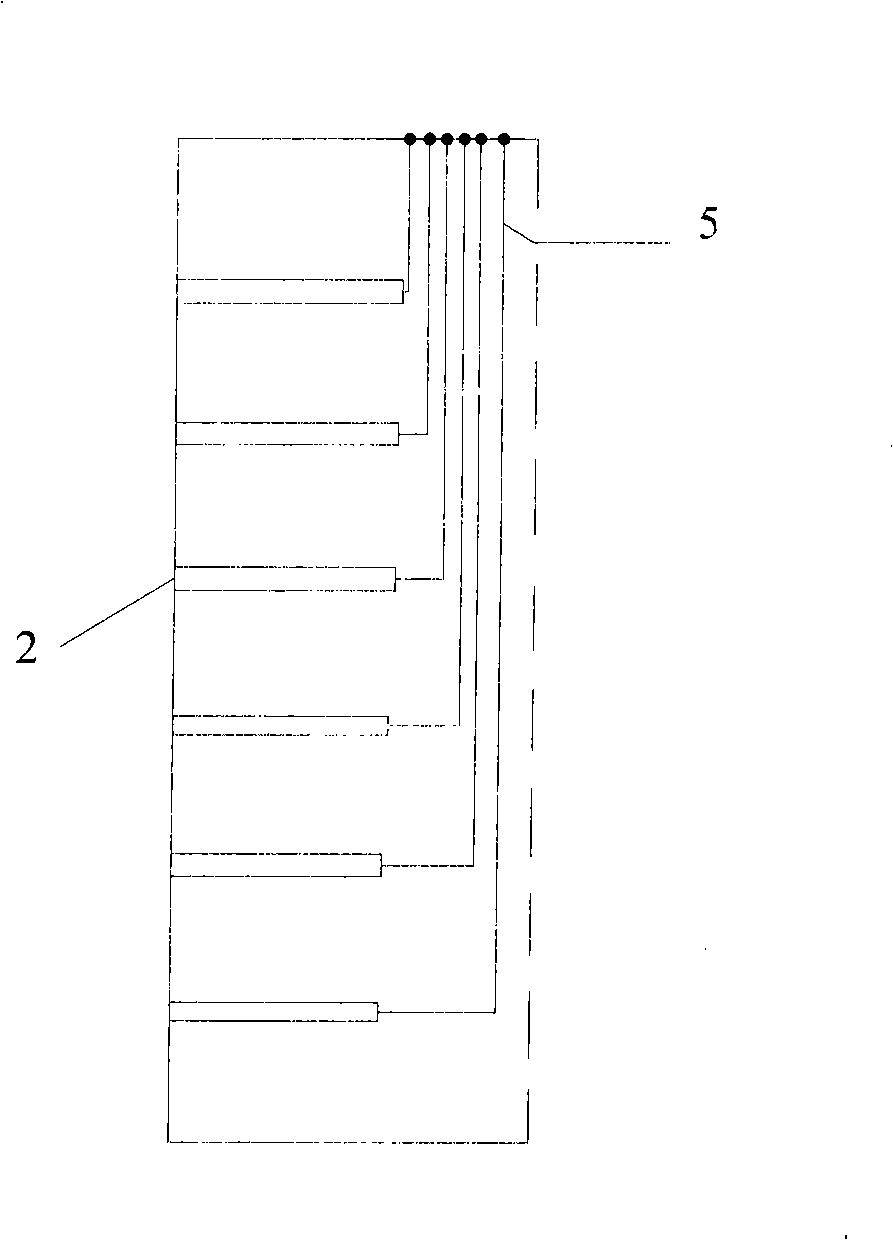

[0022] See attached figure 1 , 2 , the sensor of the present invention includes: a metal cylinder 1 with a longitudinal opening, a strain gauge 2, a waterproof pressure film 3, a concrete filling core 4, and a signal transmission line 5, the longitudinal opening of the metal cylinder 1 is stitched and connected, and the outer surface of the metal cylinder 1 is axially equidistant Paste a plurality of strain gauges 2, and the strain gauges 2 only need to cover a part of the circumference of the metal cylinder 1, and attach figure 2 The dotted line in the middle indicates the position covered by the strain gauge; a small hole is drilled on the metal cylinder 1 where the strain gauge 2 is covered, and the signal transmission line 5 connecting the strain gauge 2 is axially laid on the inner surface of the metal cylinder 1 through the small hole. The signal transmission line 5 starts from the corresponding strain gauge 2 and ends at the top of the metal cylinder 1 (generally loca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com