Separation method of electromagnetic separator and ferromagnetic material

A technology of electromagnetic separation and magnetic field, applied in the fields of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of reducing the magnetomotive force, reducing the collection efficiency of ferromagnetic materials, etc., and achieve the effect of stabilizing the magnetic field and the magnetomotive force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

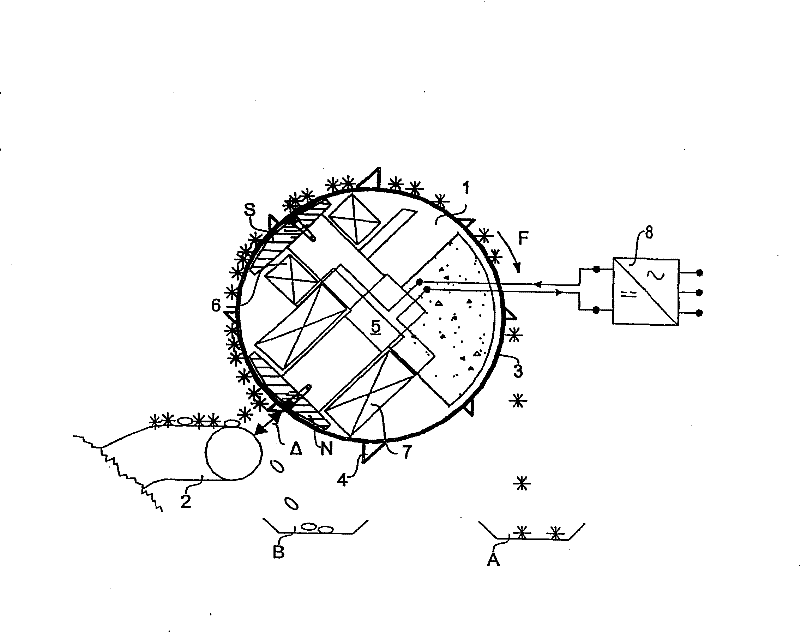

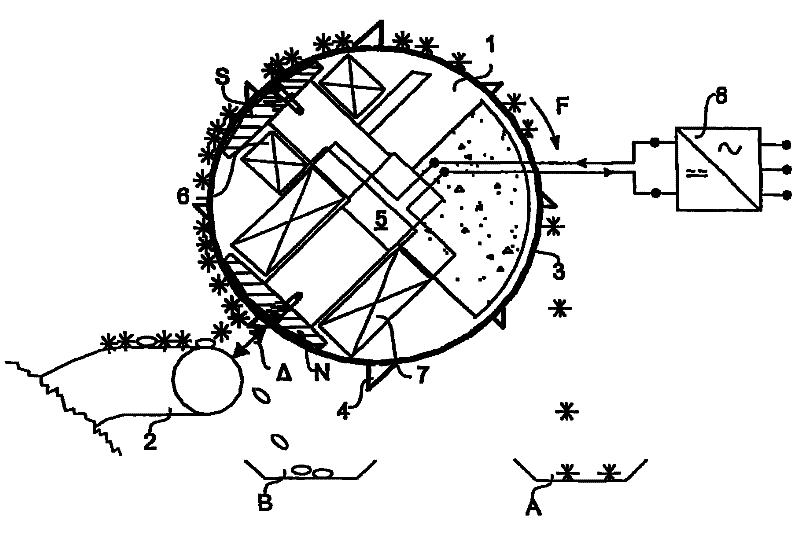

[0016] The drum 1 includes a cylindrical shell 3 that can be rotated about its axis by, for example, a motor and a transmission chain. In the figure, the arrow F indicates the possible way of rotation of the drum 1. The cylindrical shell 3 has a plurality of raised contours 4, which are arranged along the longitudinal direction of the drum parallel to the drum shaft, and are used to help convey the iron adsorbed by the drum 1 on the surface of the casing 3 during the rotation of the drum. Magnetic material. The solenoids 6 and 7 are arranged in a cavity 5 closed by the cylindrical shell 3 of the drum 1, and the solenoids are connected to a continuous current power source 8 provided outside the drum. These solenoids 6 and 7 are powered by a continuous current to generate a magnetic field capable of adsorbing ferromagnetic materials on the drum 1 from the material conveyed by the conveyor 2. The material conveyed by the conveyor 2 has a small form factor, such as Equal to 2.5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com