Electroluminescent lamp membrane switch

A membrane switch, light-emitting lamp technology, applied in the direction of electrical switches, electrical components, legends, etc., can solve the problems of contamination of transparent conductive layers, electrical connection interference, etc., and achieve the effect of reducing the total thickness, production cost and processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

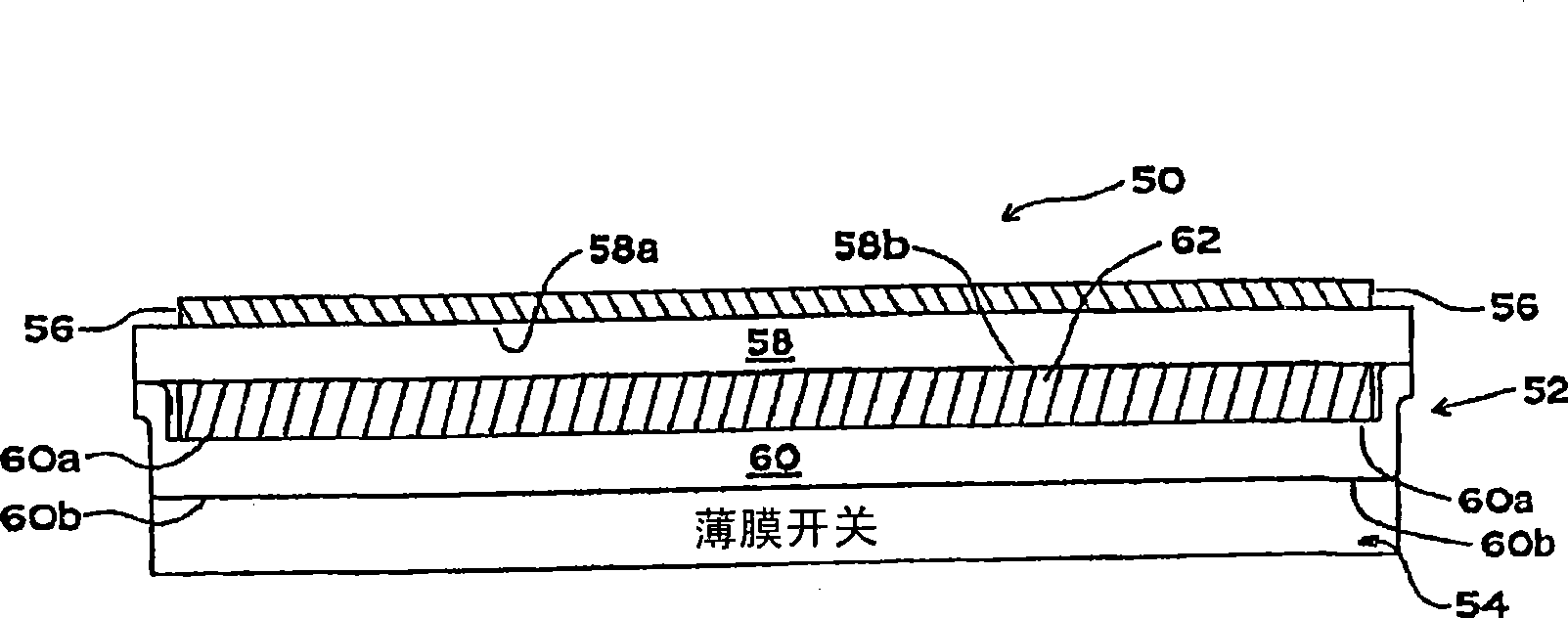

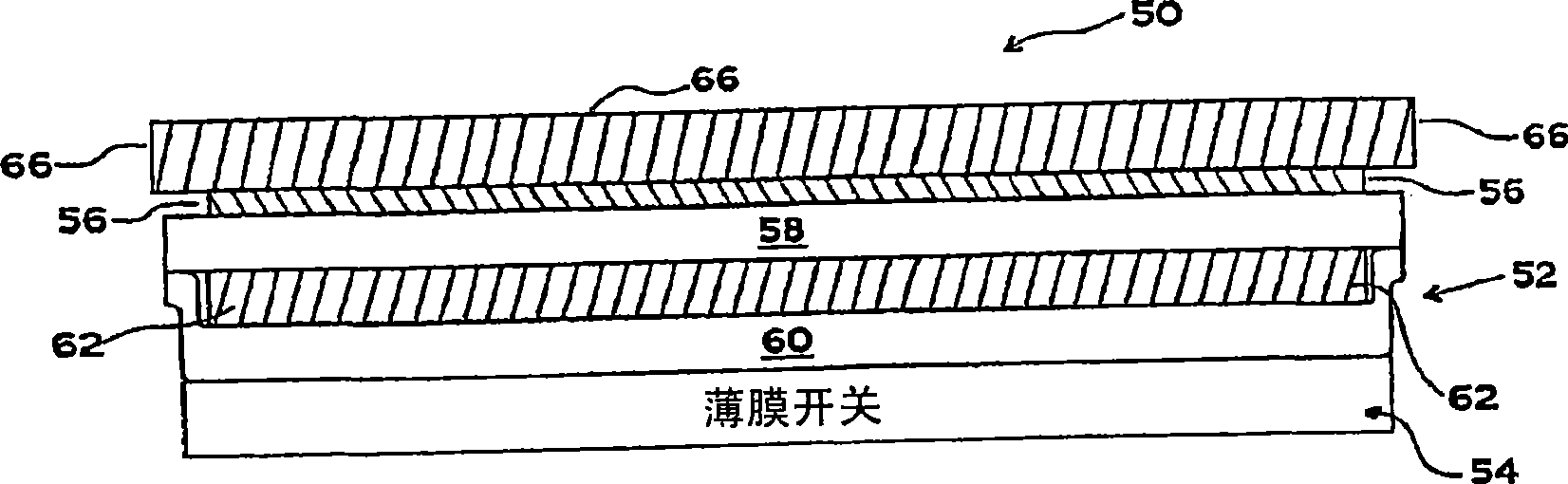

[0038] refer to figure 2 , which shows a continuous printed EL lamp membrane switch assembly of the present invention, generally identified by the reference numeral 50 . The switch 50 includes an electroluminescent lamp membrane system, generally identified at 52 , a membrane switch, generally identified at 54 , and a graphic layer 56 . The lamp system 52 includes a top insulating layer 58 and a bottom insulating layer 60 . The top layer 58 has a front surface 58a and a rear surface 58b. The bottom insulating layer 60 includes a front surface 60a and a rear surface 60b. An electroluminescent lamp 62 is disposed between insulating layers 58 and 60 . lamp 62 included next will refer to Figure 8 Each layer is described. For example, lamp 62 may comprise an electroluminescent lamp as shown and described in US Patent No. 5,856,030, the relevant disclosure and drawings of which are incorporated herein by reference.

[0039] The top insulating layer 58 of the light system 52 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com