Film or laminate comprising ethylene resin or ethylene resin composition

A technology of vinyl resin and resin composition, which is applied in the field of laminates, can solve the problems of difficult film bubble stability, extrusion load, etc., and achieve the effect of excellent mechanical strength, excellent sealing strength, and excellent balance of tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

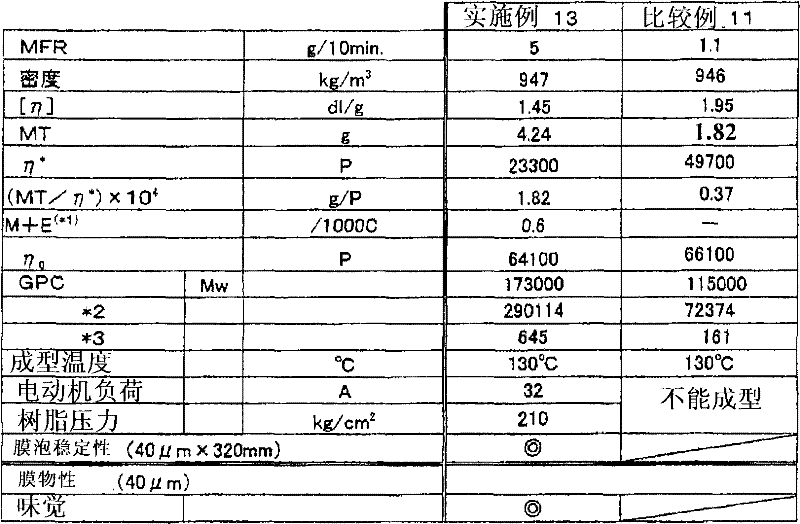

[0206] Hereinafter, the present invention will be specifically described based on examples, but the present invention is not limited by these examples. Among the analysis methods and evaluation methods of vinyl resins used in the present invention, methods not described above are as follows.

[0207] [m1] Number average molecular weight (Mn), Z average molecular weight (Mz), ratio of weight average molecular weight to number average molecular weight (Mw / Mn), ratio of Z average molecular weight to weight average molecular weight (Mz / Mw)

[0208] Number average molecular weight (Mn), Z average molecular weight (Mz), ratio of weight average molecular weight to number average molecular weight (Mw / Mn), ratio of Z average molecular weight to weight average molecular weight (Mz / Mw), using GPC produced by Waters / V2000, measure according to the following operations. Shodex AT-G was used for the guard column, two pieces of AT-806 were used for the analytical column, the column tempe...

manufacture example 1

[0283] [Preparation of solid content (S-1)]

[0284] In a reactor with an inner volume of 260 liters, the silicon dioxide (SiO 2 : Average particle size: 12 µm) 10 kg was suspended in 90.5 liters of toluene, and then cooled to 0 to 5°C. To this suspension, 45.5 liters of a toluene solution of methylaluminoxane (3.0 mmol / ml in terms of Al atoms) was added dropwise over 30 minutes. At this time, the temperature in the system was maintained at 0 to 5°C. After continuing the reaction at 0-5°C for 30 minutes, the temperature was raised to 95-100°C in about 1.5 hours, and the reaction was continued at 95-100°C for 4 hours. Thereafter, the temperature was lowered to normal temperature, and the supernatant was removed by decantation. After washing the solid content obtained by the above operation twice with toluene, toluene was added to make the total amount 129 liters, and a toluene slurry of the solid content (S-1) was prepared. A part of the obtained solid content and a researc...

manufacture example 2

[0296] [Manufacturing example 2]~[Manufacturing example 4]

[0297] [polymerization]

[0298] In Production Example 1, except that the polymerization conditions were changed to those shown in Table 1, an ethylene-based polymer was obtained in the same manner as in Production Example 1 (see Table 1). Using the obtained ethylene-based polymer, a measurement sample was prepared in the same manner as in Production Example 1. Table 5 and Table 10 show the results of physical property measurement and extrusion lamination molding using this sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com