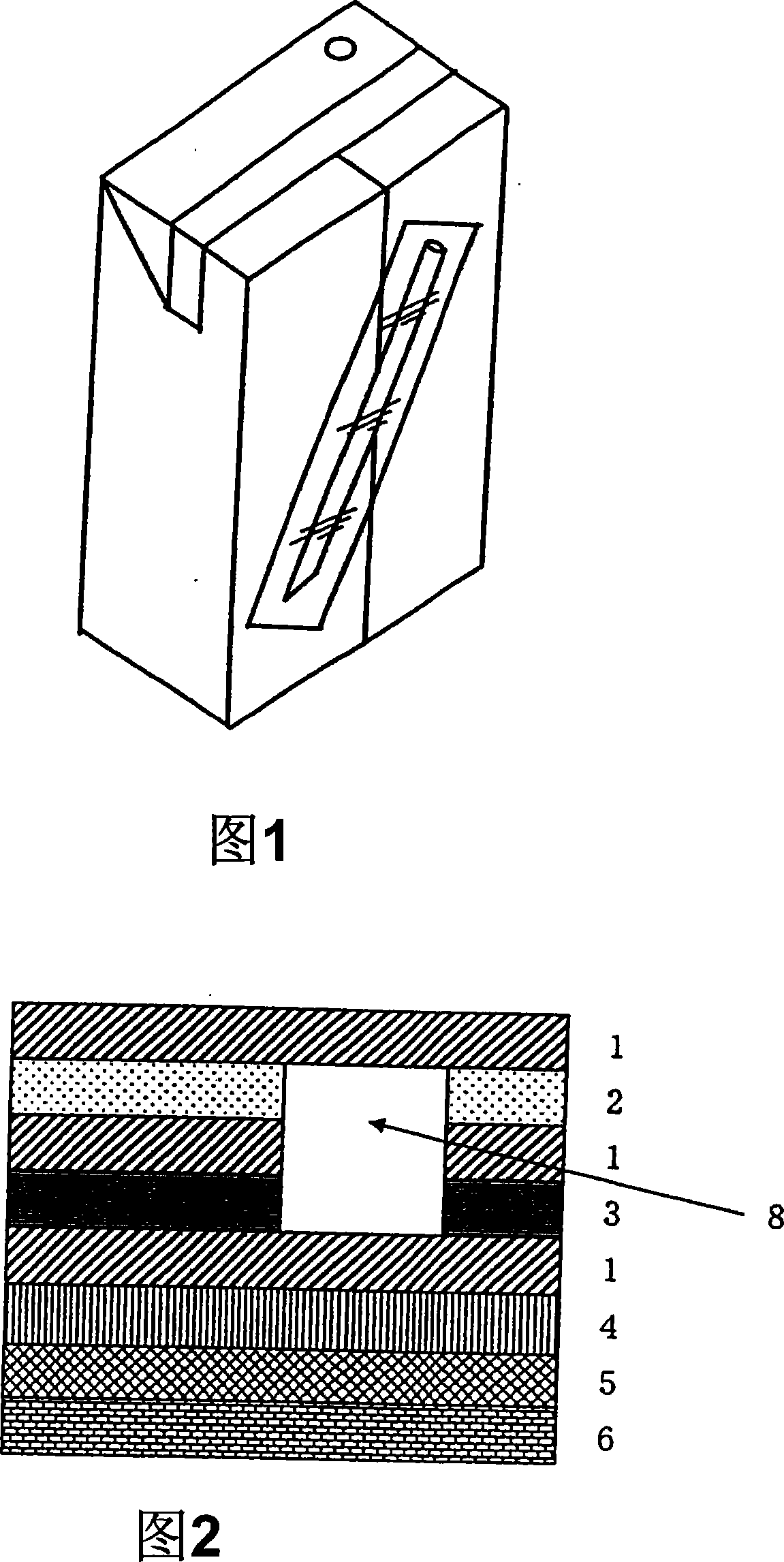

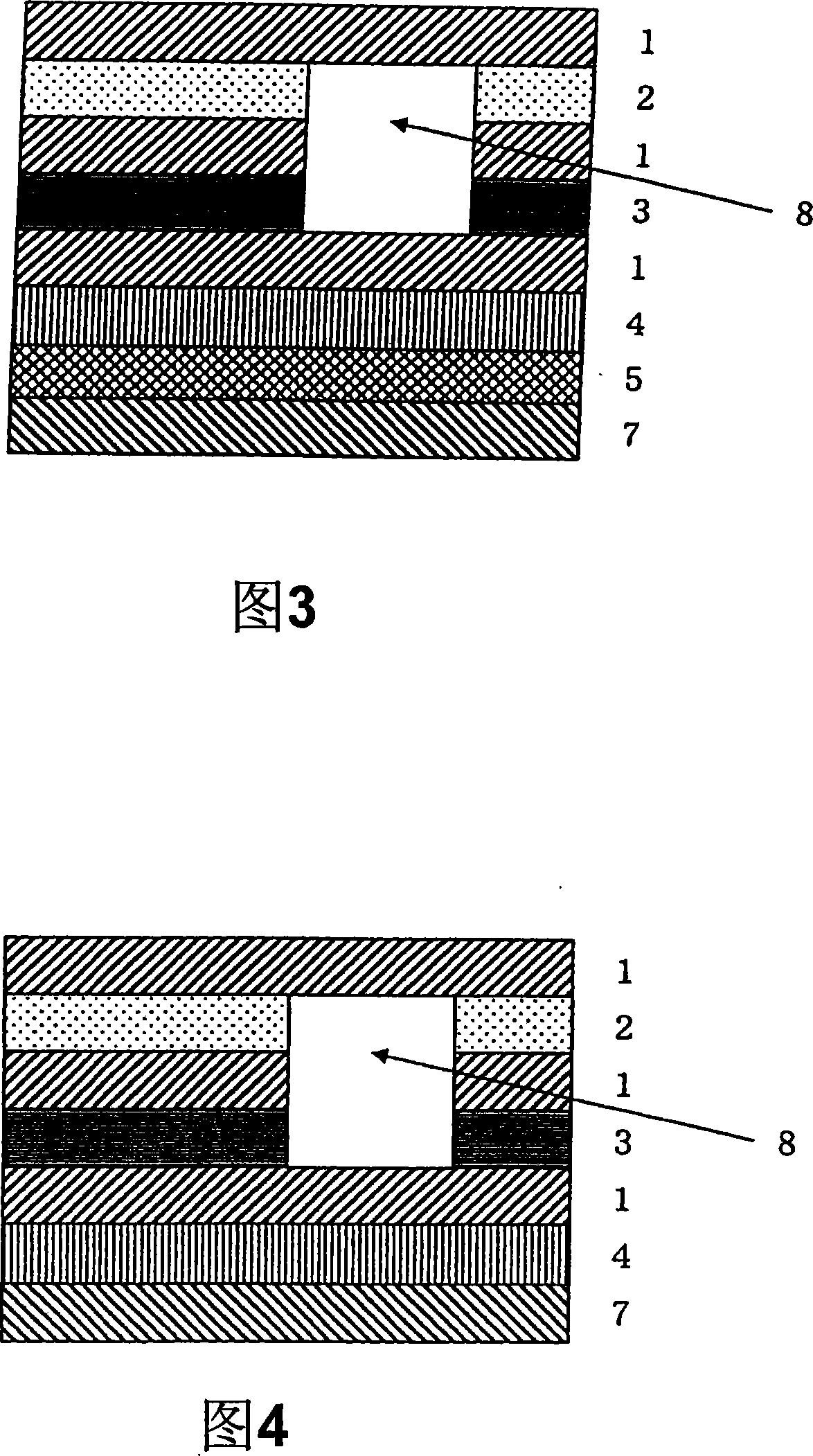

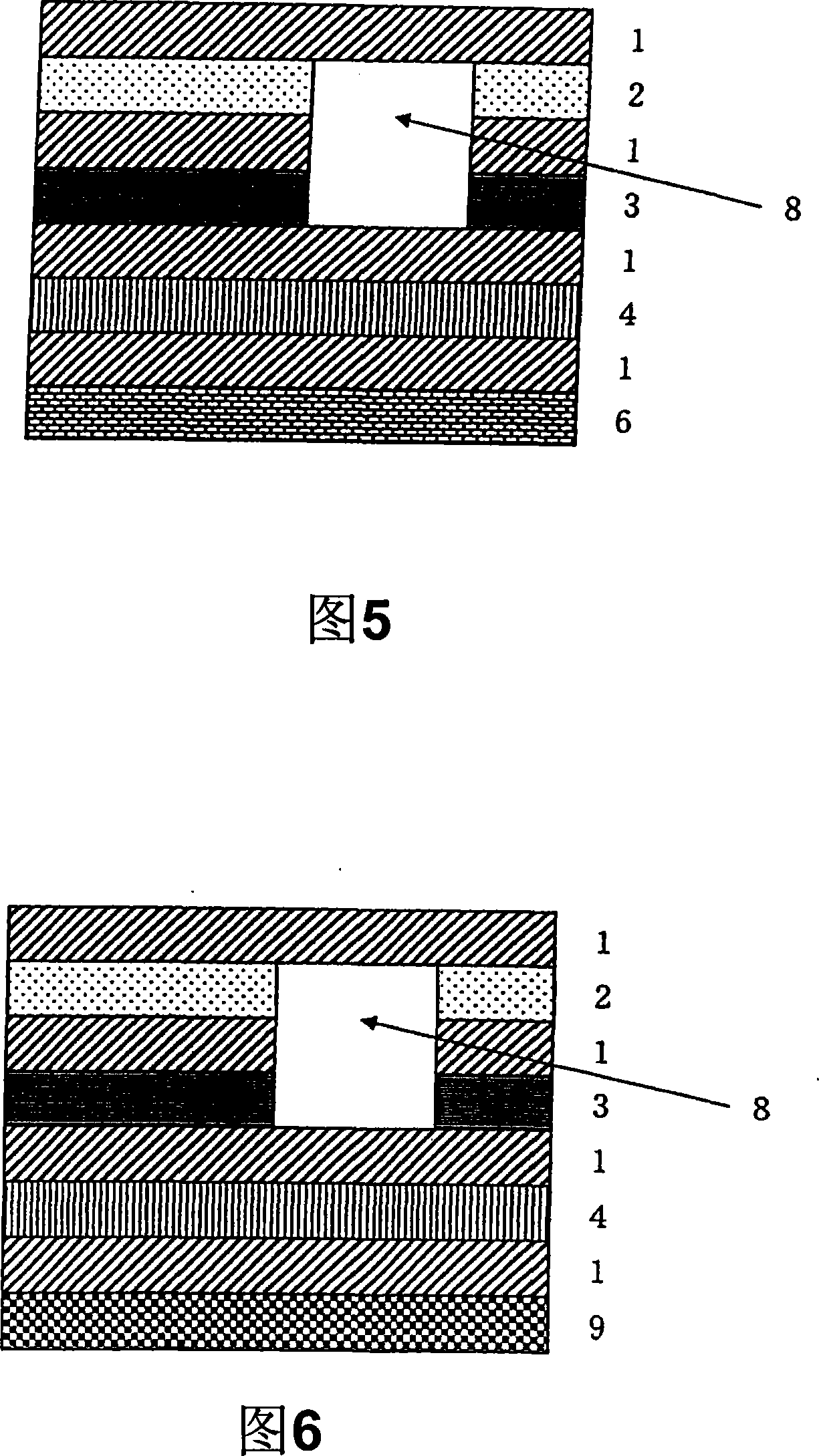

Multilayer polyolefin film for use in paper container for liquids, material for use in paper container for liquids comprising the same, and paper container for liquids using the same

A paper container and polyolefin technology, applied in the field of polyolefin film, can solve the problems of insufficient performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0144] First, a biaxially stretched laminated polyolefin film serving as a strength-imparting layer was produced as follows.

[0145] The propylene-ethylene random copolymer (4.6% by weight of monomer units derived from ethylene, melting point of 135° C., and MFR of 2.1 g / 10 minutes) as the resin A constituting the first layer of the polyolefin film was 95% by weight, The propylene-ethylene random copolymer (0.4% by weight of monomer units derived from ethylene, melting point of 156° C., and MFR of 2.3 g / 10 minutes) as resin B constituting the first layer of polyolefin film was 5% by weight, mixed Resin A and resin B, make the resin of polyolefin film I layer.

[0146] A propylene-ethylene random copolymer (0.4% by weight of monomer units derived from ethylene, melting point of 156° C., MFR of 2.3 g / 10 minutes) as the resin C constituting the biaxially oriented oriented polyolefin film II layer 60% by weight, propylene-ethylene-1-butene terpolymer (6.2% by weight of monomer u...

Embodiment 2

[0176] The liquid paper container material of the present invention is produced as follows.

[0177] As the sealing layer A layer, a three-layer non-stretched polyolefin film with a total thickness of 30 μm laminated in the order of a / b / c was produced by three-layer co-extrusion, wherein a) was mixed with 50% by weight Propylene-ethylene random copolymer (3.6% by weight of monomer units derived from ethylene, melting point of 146° C., MFR of 7.0 g / 10 minutes) and 50% by weight of ethylene-1-butene copolymer (derived from 1- Butene monomer unit is 17% by weight, melting point is 63 ℃, MFR is 4.9g / 10 minutes) the layer that the thickness that constitutes of the resin of 4.9g / 10 minutes); The monomer unit derived from ethylene is 3.6% by weight, the melting point is 146° C., the MFR is 7.0 g / 10 minutes) and 30% by weight of ethylene-1-butene copolymer (the monomer unit derived from 1-butene is 17 % by weight, a melting point of 63° C., and a MFR of 4.9 g / 10 minutes), a layer hav...

Embodiment 3

[0184] The liquid paper container material of the present invention is produced as follows.

[0185] As the sealing layer A layer, a three-layer non-stretched polyolefin film with a total thickness of 30 μm laminated in the order of a / b / c was prepared by three-layer co-extrusion, wherein a) was mixed with 40% by weight Propylene-ethylene random copolymer (3.6% by weight of monomer units derived from ethylene, melting point of 146° C., MFR of 7.0 g / 10 minutes) and 60% by weight of ethylene-1-hexene copolymer (derived from 1- The monomer unit of hexene is 11% by weight, melting point is 100 ℃, MFR is 8.0g / 10 minutes) the layer that the thickness that constitutes of the resin of 8.0g / 10min); 3.6% by weight of monomer units derived from ethylene, melting point of 146° C., MFR of 7.0 g / 10 minutes) and 30% by weight of ethylene-1-butene copolymer (16% by weight of monomer units derived from 1-butene % by weight, a melting point of 66° C., and a MFR of 4.0 g / 10 minutes), a layer hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com