Production method of vertical stone blocking net

A stone-blocking net and vertical technology, which is applied in the field of making vertical stone-blocking nets by using waste tires, can solve the problems of high cost, rolling stones are easy to pass through, and loss of cushioning performance, etc., achieving low cost, significant economic and social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

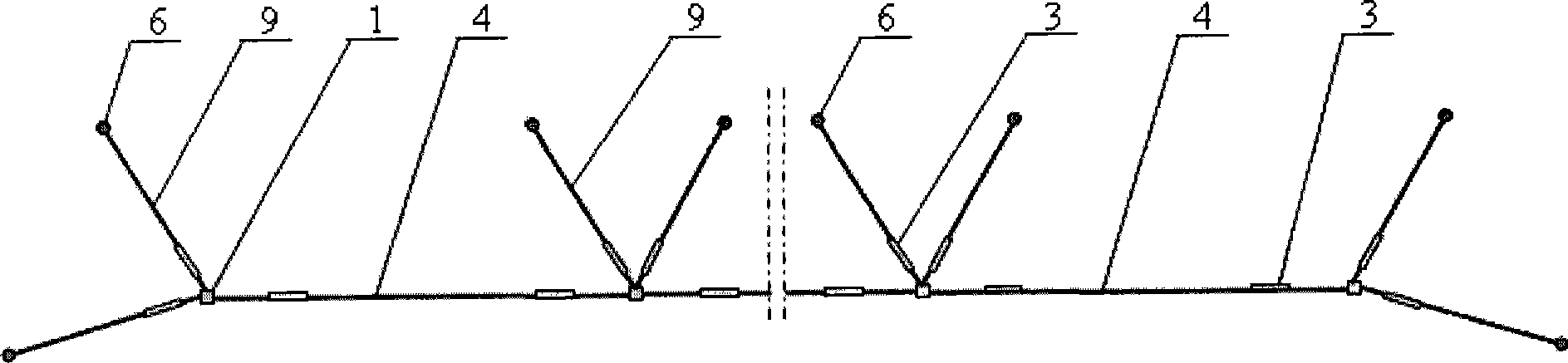

[0045] An embodiment of the present invention provides a method for manufacturing a vertical stone blocking net. Refer below figure 1 A to figure 1 D, specify the manufacturing method of this vertical stone blocking net, this method comprises:

[0046] Step S110: Determine the protection strength and protection range of the slope, and determine the construction conditions;

[0047] Step S120: setting up a rock-block net support structure on the slope;

[0048] Step S130: install the waste tire mesh; and

[0049] Step S140: filling the gaps in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com