Conductive concrete doped with conductive material

A conductive concrete and conductive material technology, applied in the field of concrete, can solve the problems of high cost, corrosion, and non-use of carbon fiber, and achieve the effects of increasing the contact area, convenient construction, and reducing resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

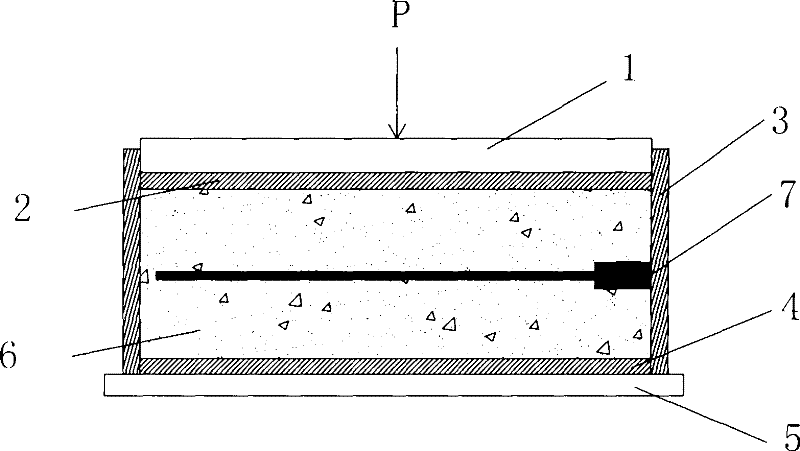

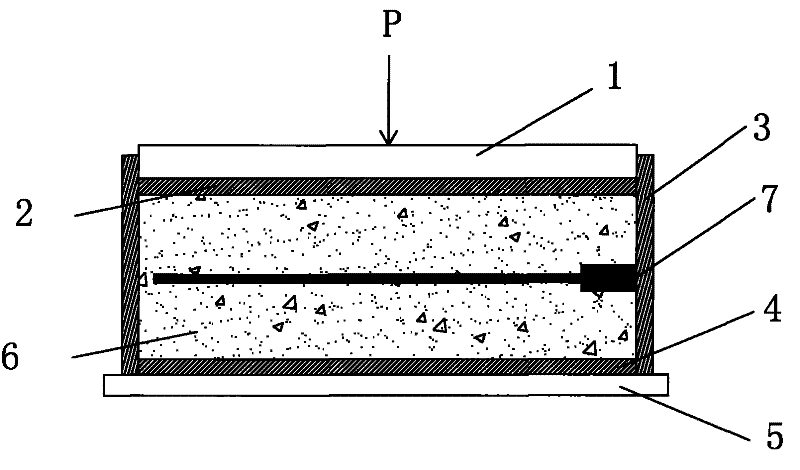

[0014] In terms of weight percentage, after mixing 15% cement, 25% iron ore, 25% graphite, 15% pebbles and 20% water, mix the mixture with a cement mortar mixer for 3 to 5 minutes and pour it into Such as figure 1 In the mold shown, cover the pressure plate 1 and pressurize the pressure plate 1. The pressure P of the pressure plate 1 is 80-100kg / cm 2 , Press the mixture for 5-8 seconds and then demould to make conductive concrete. The compressive strength of conductive concrete is 17.2Mpa, and its resistivity is 1.1×10 -3 Ω·m.

Embodiment 2

[0016] In terms of weight percentage, after mixing 30% cement, 15% iron ore, 15% graphite, 30% pebble and 10% water, mix the mixture with a cement mortar mixer for 3 to 5 minutes and pour it into Such as figure 1 In the mold shown, cover the pressure plate 1 and pressurize the pressure plate 1. The pressure P of the pressure plate 1 is 80-100kg / cm 2 , Press the mixture for 5-8 seconds and then demould to make conductive concrete. The compressive strength of conductive concrete is 23.3Mpa, and its resistivity is 8.2×10 -3 Ω·m.

Embodiment 3

[0018] In terms of weight percentage, after mixing 25% cement, 20% iron ore, 20% graphite, 20% pebbles and 15% water, mix the mixture with a cement mortar mixer for 3 to 5 minutes and pour it into Such as figure 1 In the mold shown, cover the pressure plate 1 and pressurize the pressure plate 1. The pressure P of the pressure plate 1 is 80-100kg / cm 2 , Press the mixture for 5-8 seconds and then demould to make conductive concrete. The compressive strength of conductive concrete is 20.9Mpa, and its resistivity is 3.1×10 -3 Ω·m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com