Method for producing and eating instant ginkgo powder

A production method and technology of ginkgo powder, applied in the fields of application, food preparation, food science, etc., to achieve the effect of simple method, rich nutrition, and easy large-scale factory production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

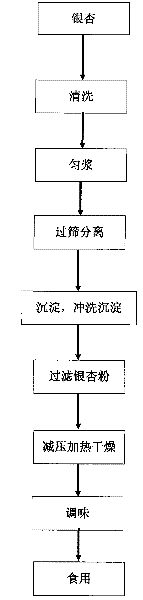

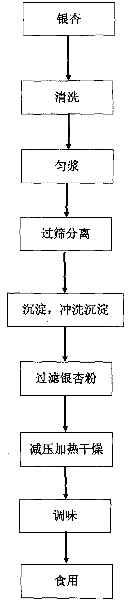

Image

Examples

Embodiment 1

[0020] Wash 50kg of fresh ginkgo fruit, add 50L of water to a large traditional Chinese medicine powder machine, set the speed at 3000rpm / min, and homogenate for 3min. Pass the homogenate through an 80-mesh sieve to obtain a ginkgo seed homogenate without hard mesocarp and membranous endoderma. Seed kernels were homogenized and precipitated for 4 hours, the precipitate was collected, mixed with 30 L of water, washed, vacuum filtered with filter paper, and ginkgo powder was obtained. Put the ginkgo powder in a vacuum oven, vacuum 0.08MPa, dry at 70°C for 50 minutes, and then dry at 100°C for 10 minutes to obtain dry ginkgo powder. The yield of ginkgo powder is 25-30% of the fresh weight of ginkgo fruit. According to 15-25% of the dry weight of the ginkgo powder, sucrose is added and mixed evenly to obtain the finished product of the instant ginkgo powder.

[0021] Put 25g of the finished ginkgo powder in a food dish, add 20mL of boiling water (100°C) and mix thoroughly, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com