High-tensile strength welded steel tube for structural partsof automobiles and method of producing the same

A technology for welding steel pipes and automobile structures, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of low ductility, unsuitability, poor formability, etc., and achieve excellent low temperature toughness, improved characteristics, and excellent formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] The molten steel with the composition shown in Table 1 was smelted and made into raw steel material (steel billet) by continuous casting. These steel raw materials are heated to about 1250°C, hot-rolled at a finishing temperature of about 860°C, and after hot rolling, slow-cooling at a temperature range of 750-650°C for 5 seconds, and then Coiling temperature: 590°C in the hot-rolling process to produce a hot-rolled steel strip (thickness: about 3mm).

[0108] Next, these hot-rolled steel strips are used as raw materials for steel pipes, pickled, and slit to a specified width, and then roll-formed continuously to form open pipes, and then performed by high-frequency resistance welding. This open pipe was subjected to an electric welding pipe manufacturing process of electric welding, thereby producing a welded steel pipe (outer diameter φ89.1 mm×wall thickness about 3 mm).

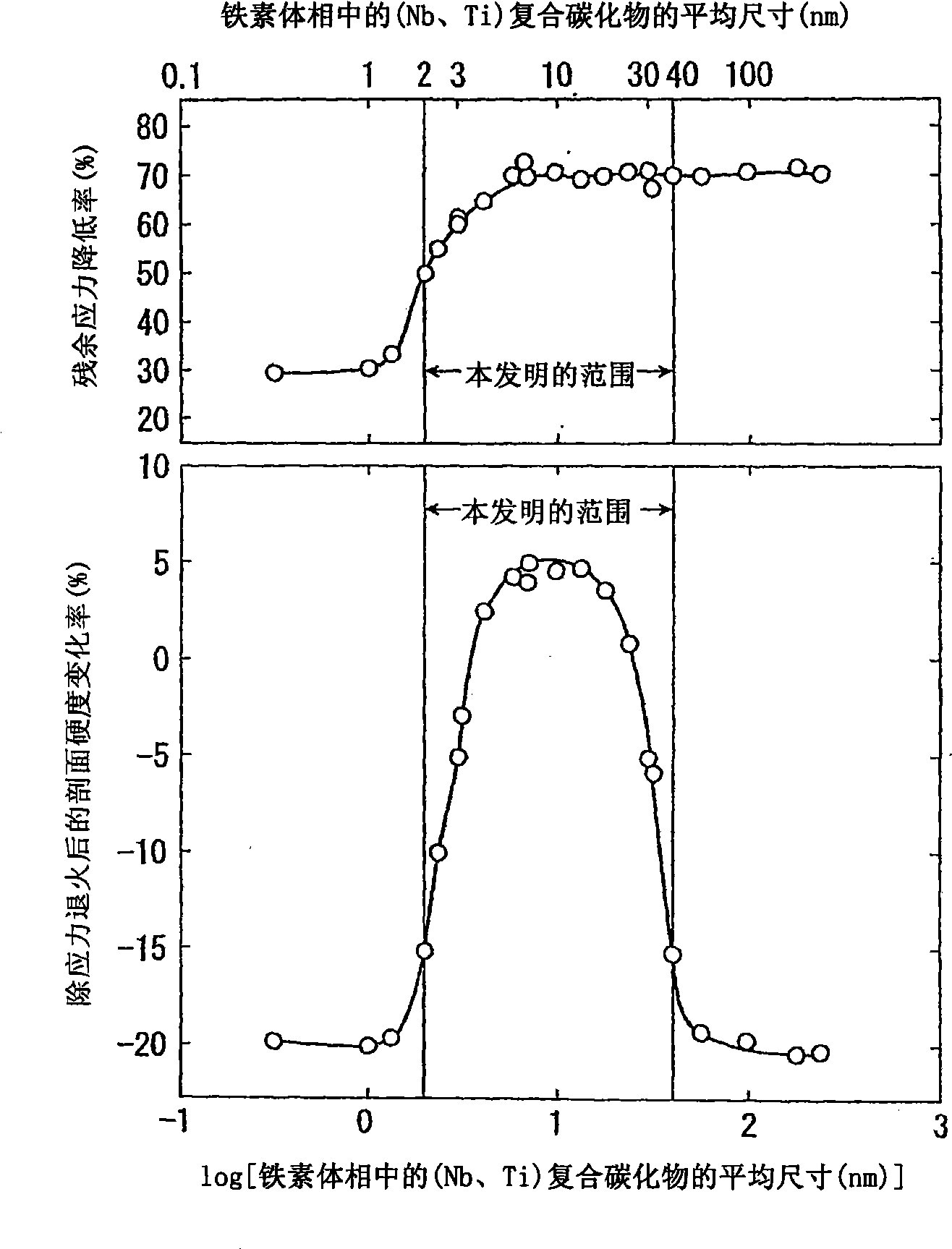

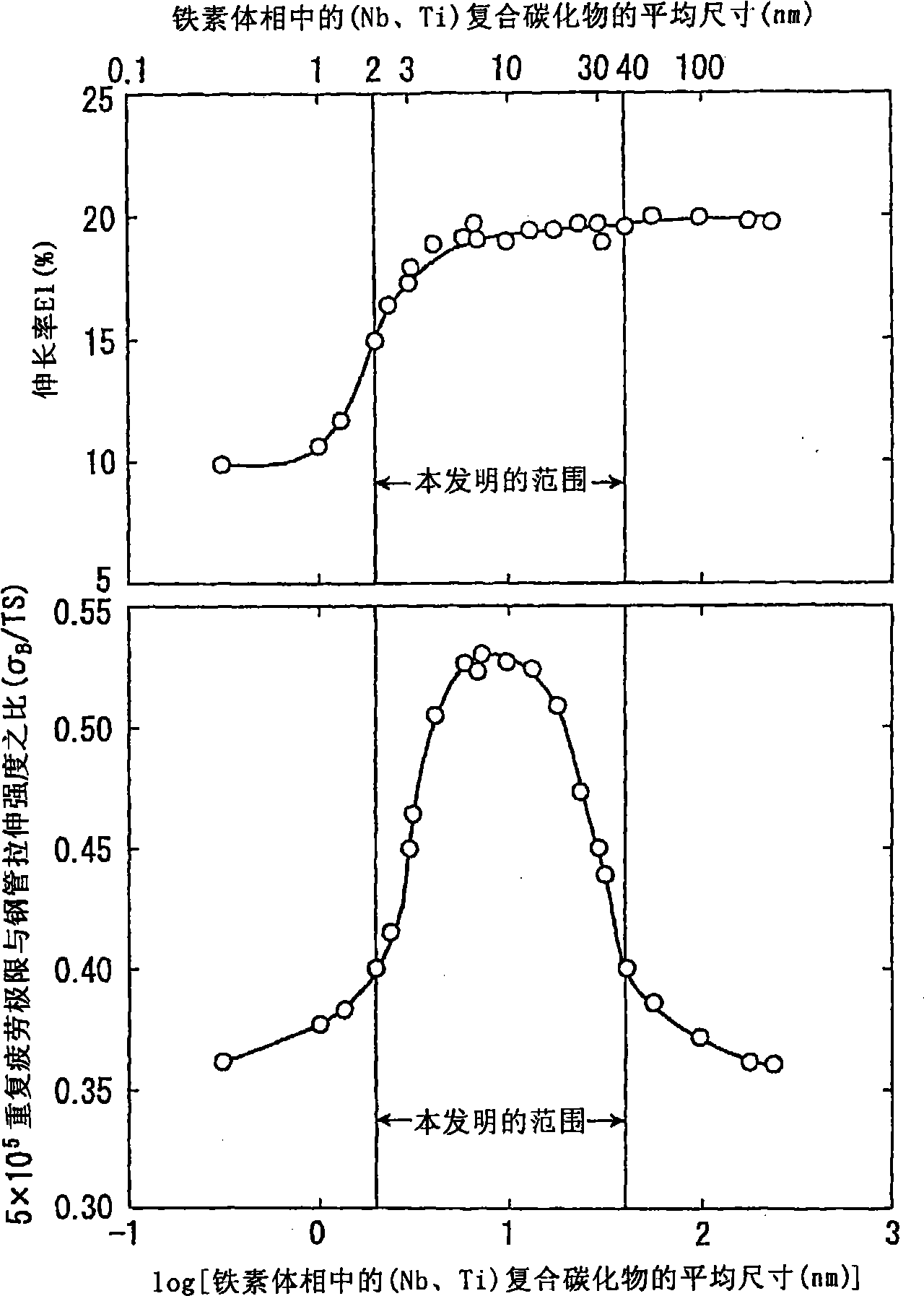

[0109] In addition, in the electric-welded pipe-making process, the width reduction rate define...

Embodiment 2

[0141] Steel raw materials (slabs) having the compositions of steel No.B and No.C in Table 1 were subjected to hot rolling under the conditions shown in Table 3 to form hot-rolled steel strips. Next, these hot-rolled steel strips are used as steel pipe raw materials, pickled, and slit into a predetermined width dimension, and then roll-formed continuously to form an open pipe, and then the open pipe is made by high-frequency resistance welding. The pipe is subjected to an electric welding pipe making process of electric welding, thereby producing a welded steel pipe (outer diameter 70 to 114.3mmφ x wall thickness t2.0 to 6.0mm). In addition, in the electric-welded pipe-making process, the width reduction rate defined by (1) formula was set to the value shown in Table 3.

[0142] From the obtained welded steel pipe, a test piece was taken in the same manner as in Example 1, and the same as in Example 1. The structure observation test, the precipitate observation test, the tensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com