Engine vent gas purification system with front and rear catalysis bodies and utilization of waste gas secondary combustion

A kind of exhaust gas purification and catalytic body technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of inability to focus on the treatment of exhaust gas, unreachable, and the exhaust gas of the engine cannot be completely purified and eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

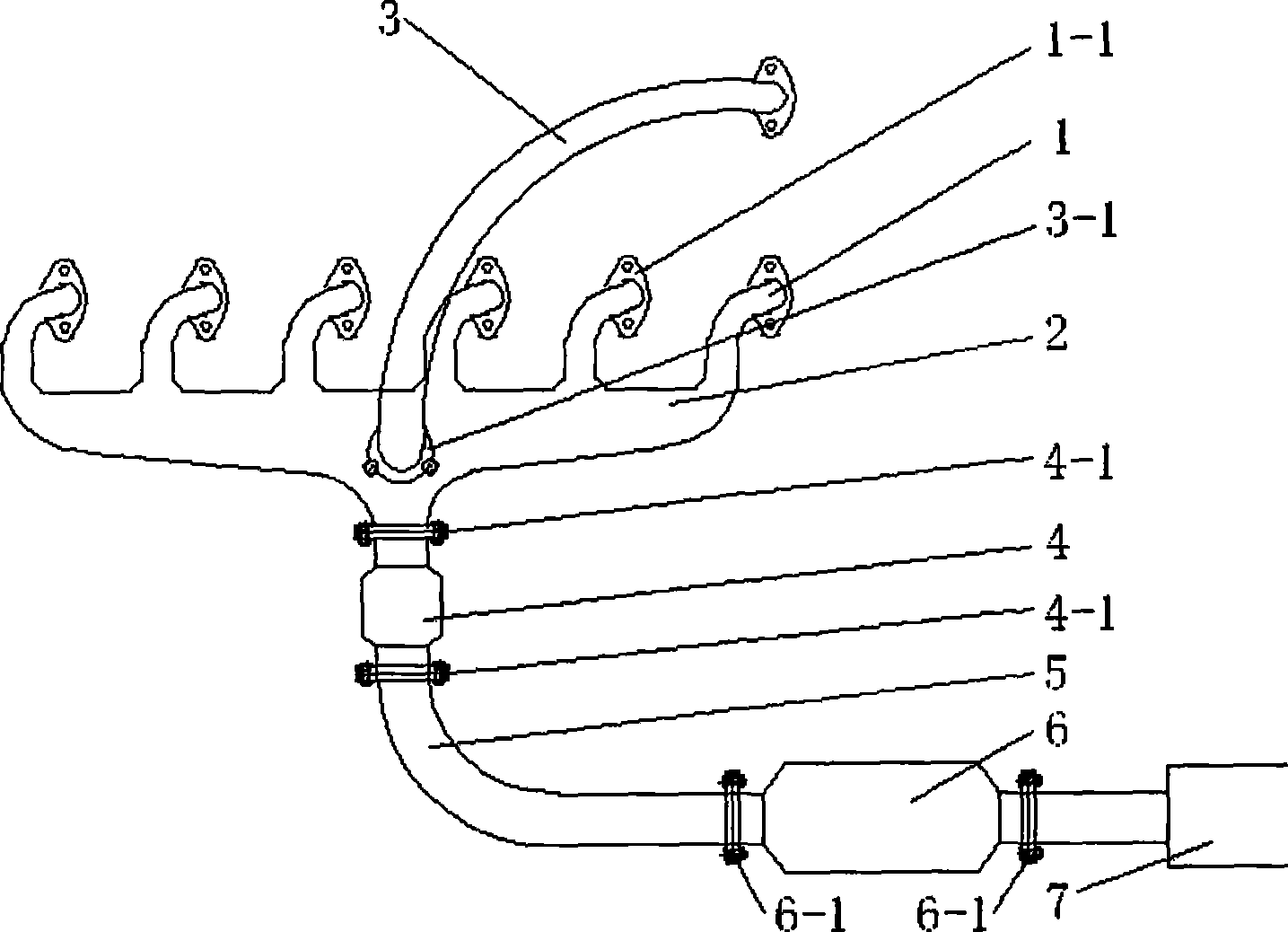

[0008] As shown in Figure 1 , the present invention includes a sub-exhaust pipe 1, an exhaust manifold 2, an exhaust gas intake pipe 3, a front catalytic body 4, an exhaust elbow 5, a rear catalytic body 6 and a muffler 7. One end of the sub-exhaust pipe 1 is connected to the engine cylinder through the flange 1-1, and the other end is connected to the exhaust main pipe 2. The number of sub-exhaust pipes 1 is equal to the number of cylinders, and the exhaust gas discharged through the engine cylinders is concentrated in the exhaust In the main pipe 2, on the exhaust main pipe 2, an air outlet hole communicating with the exhaust main pipe 2 is set. The air outlet hole is connected to the exhaust gas inlet pipe 3 through the flange 3-1, and the diameter of the exhaust gas inlet pipe 3 is the same as that of the exhaust elbow. 5 have the same diameter, so that the exhaust gas discharged from the cylinder is divided into two channels at the exhaust manifold 2, all the way through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com