Integrated control method capable of simultaneously removing inhalable particles and heavy metal from fire coal

An integrated control, heavy metal technology, applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of complex operation, obstacles to popularization and application, high operating costs, achieve developed specific surface area and activity, and improve effective utilization efficiency. , the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

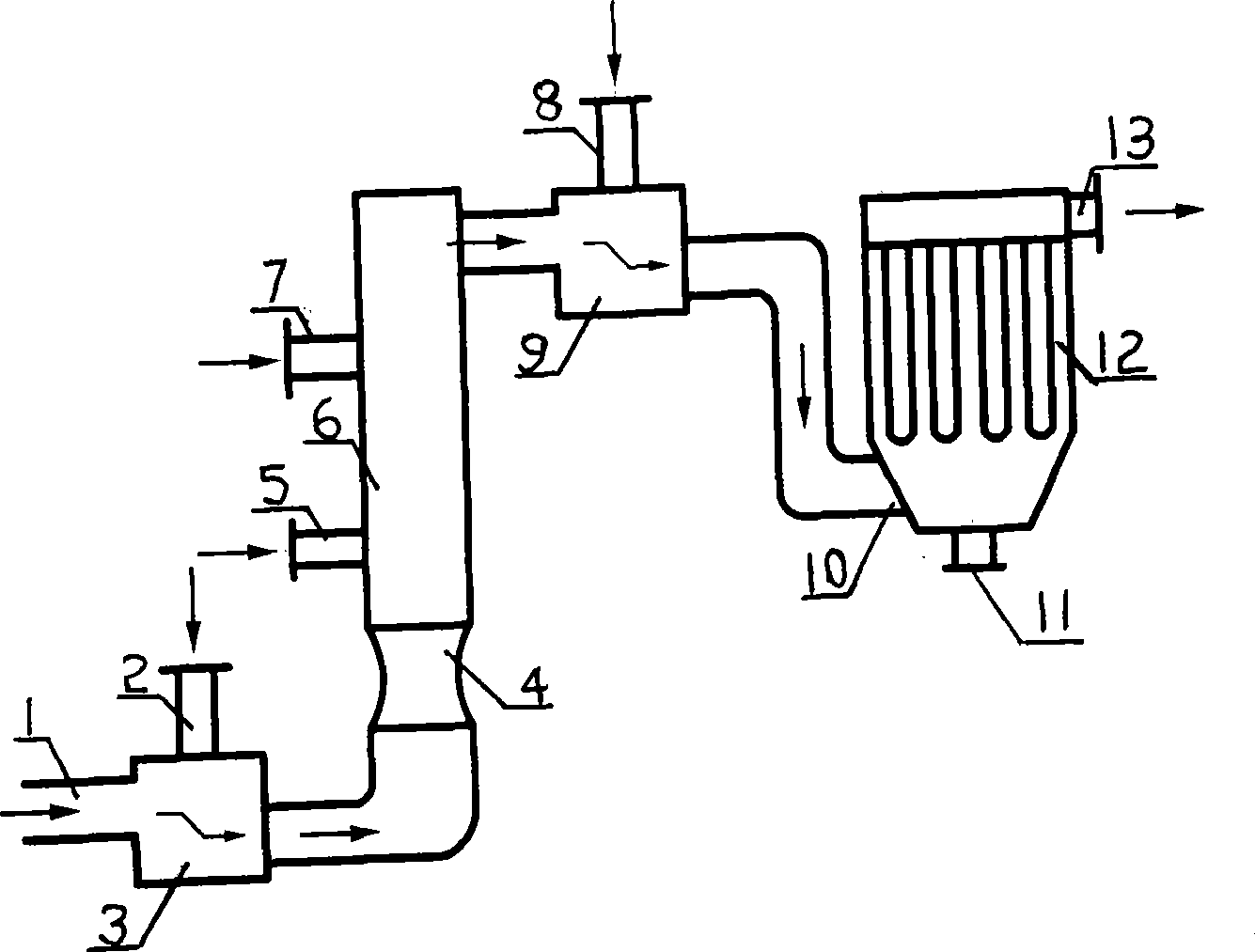

[0028] As shown in the accompanying drawings, in the specific embodiment of the integrated control method capable of simultaneously removing coal-fired inhalable particulate matter and heavy metals, fly ash residue carbon injection port a, scaling nozzle, fluidized bed reaction device, fly ash residual carbon injection inlet b, bag filter made of carbon fiber mixed with filter bag and other parts.

[0029] An integrated contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com