Method and device for carrying drum-type drying and accurate processing of tobacco shred

A drum-type and accurate technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of product quality change, unstable temperature control of the cylinder wall, and no means of monitoring air pressure, so as to improve stability and ensure normal stability. Operation and the effect of improving processing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

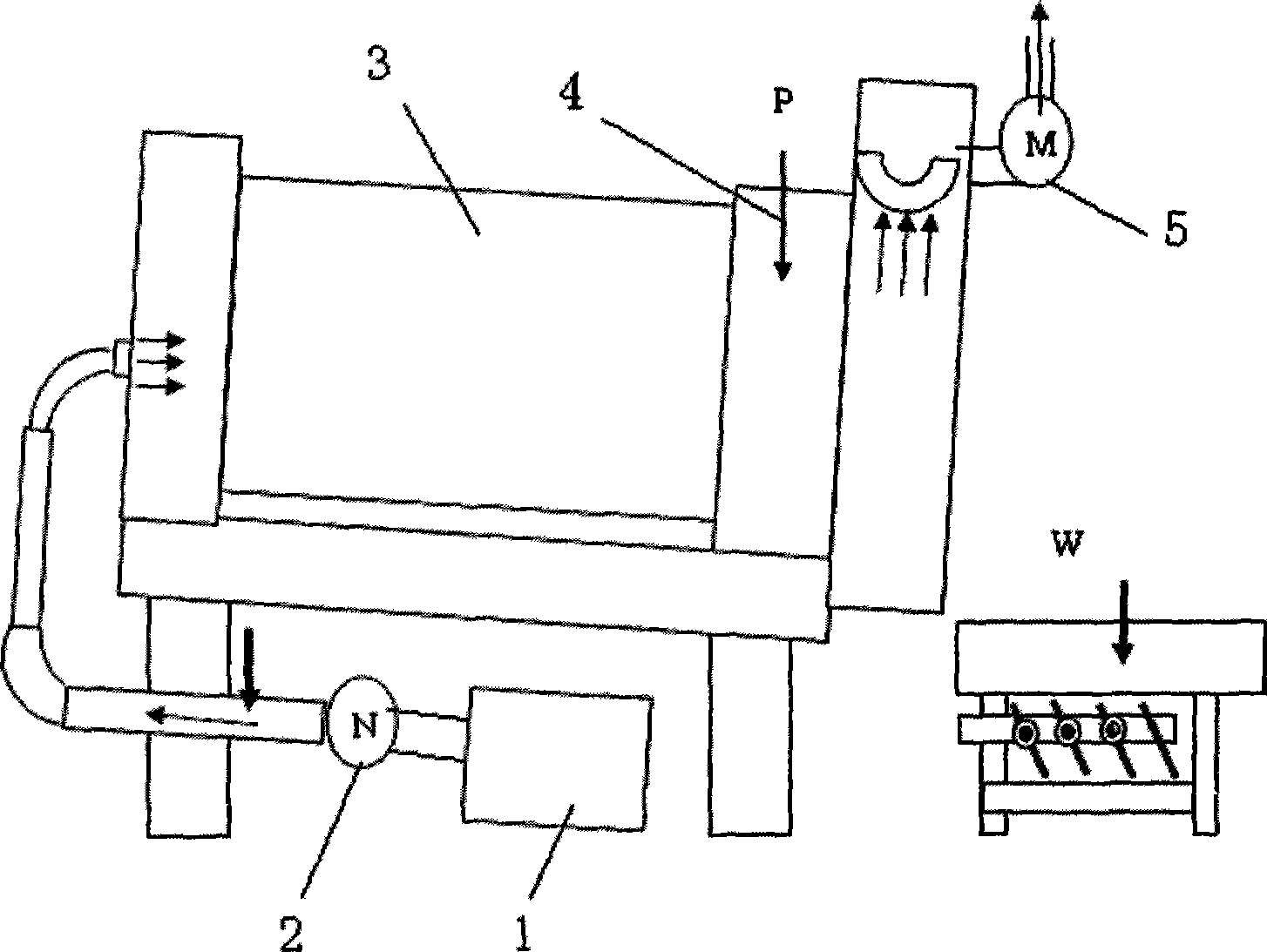

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] see figure 1 , the feeding end of drum type silk drying machine 3 is connected with heater 1 and hot air automatic valve 2, the discharge end is connected with automatic damp valve 5, and the discharge end of drum type silk drying machine 3 is equipped with pressure detector 4, the pressure The detector 4 is connected with the hot air automatic valve 2 and the automatic moisture-discharging valve 5 in chain control.

[0014] see figure 1 , the method for performing drum-type drying and precise processing on shredded tobacco, the steps are: Step 1: Set the corresponding tube wall temperature, hot air temperature T1, hot air volume N, and moisture discharge opening M according to the processing characteristics of cigarette products, and start Preheating, and put into production after the temperature in the barrel reaches the set requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com