Electric translational top cover for purge stack

A technology of exhaust tower and top cover, applied in the field of machinery, can solve the problem that the exhaust tower enters a large amount of rain and snow, affecting the normal operation of the exhaust tower, etc., and achieves the effect of ensuring normal and stable operation, convenient and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

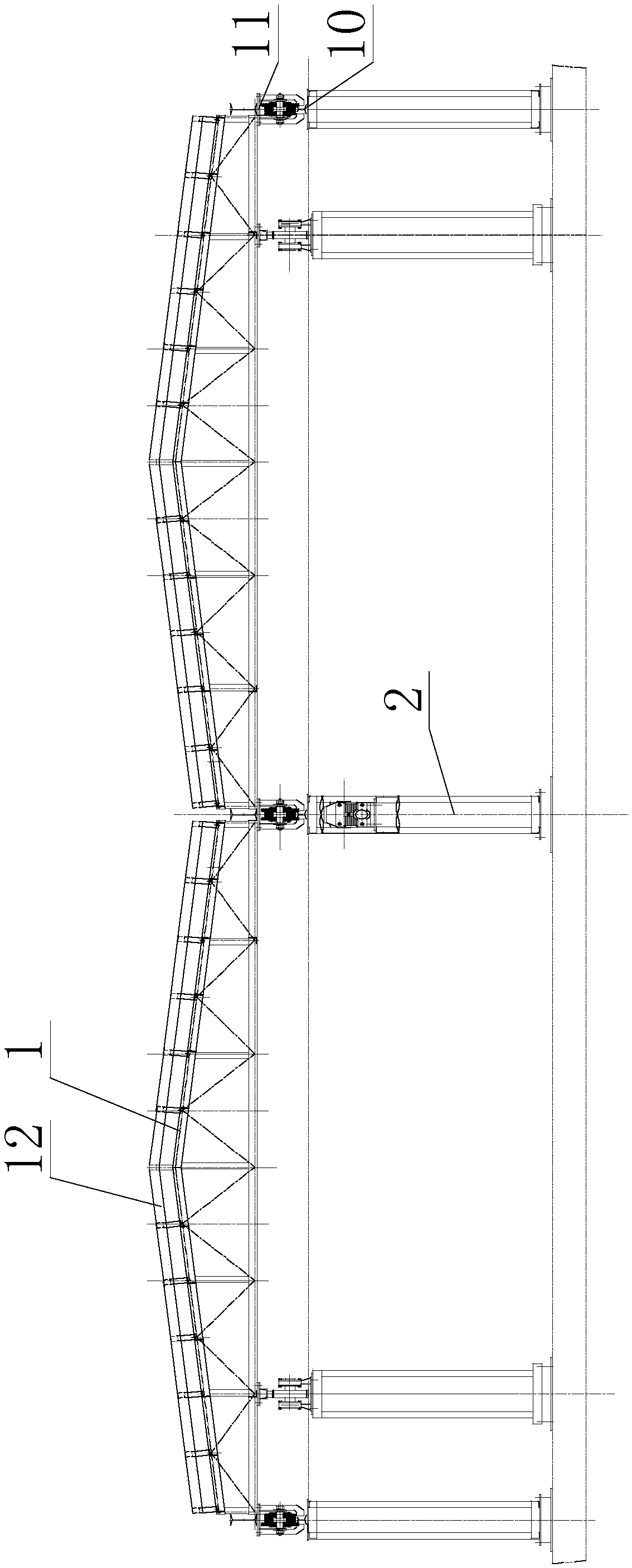

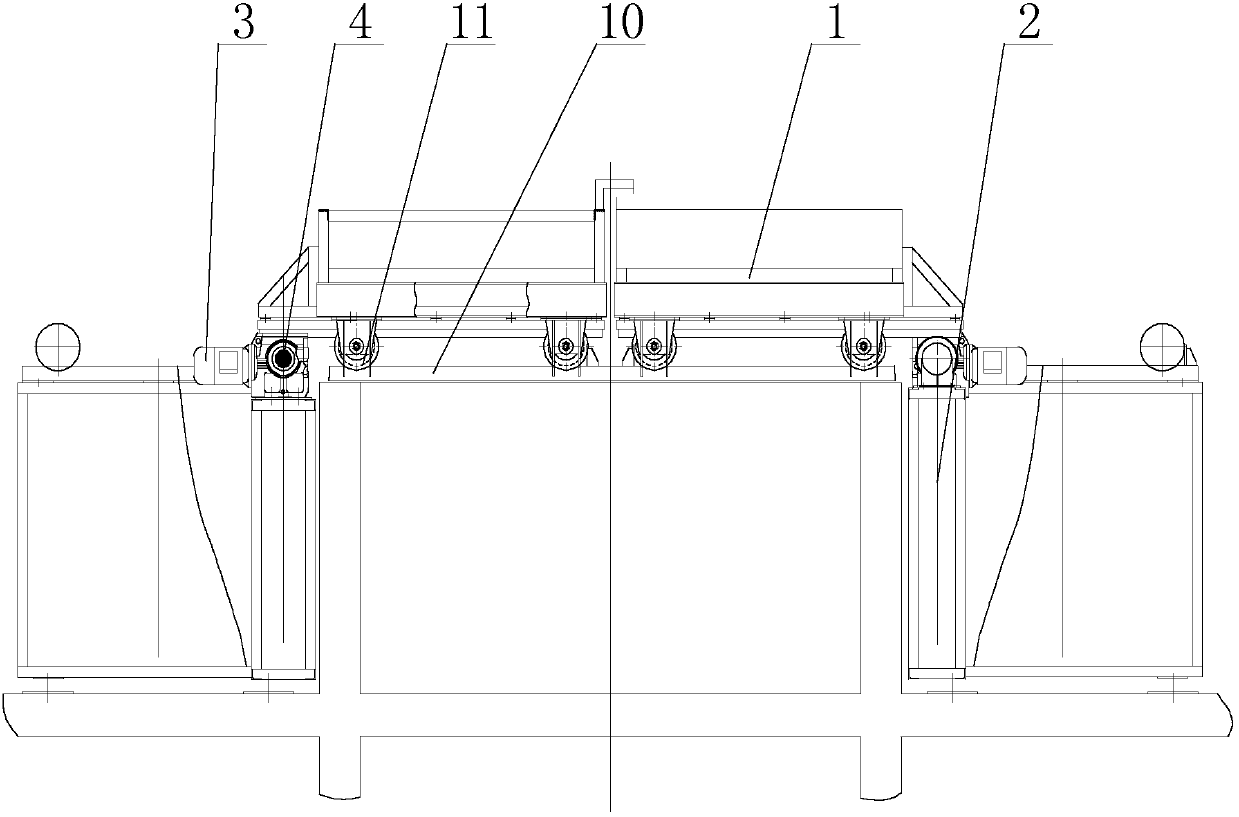

[0015] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, an electric translation roof for an exhaust tower described in this embodiment includes two roofs 1, a base bracket 2 and two drive mechanisms, the base bracket 2 is installed on the exhaust tower, and two The top cover 1 is installed on the base bracket 2 in a straight line, and the lower surface of each top cover 1 is respectively connected with one of the driving mechanisms.

specific Embodiment approach 2

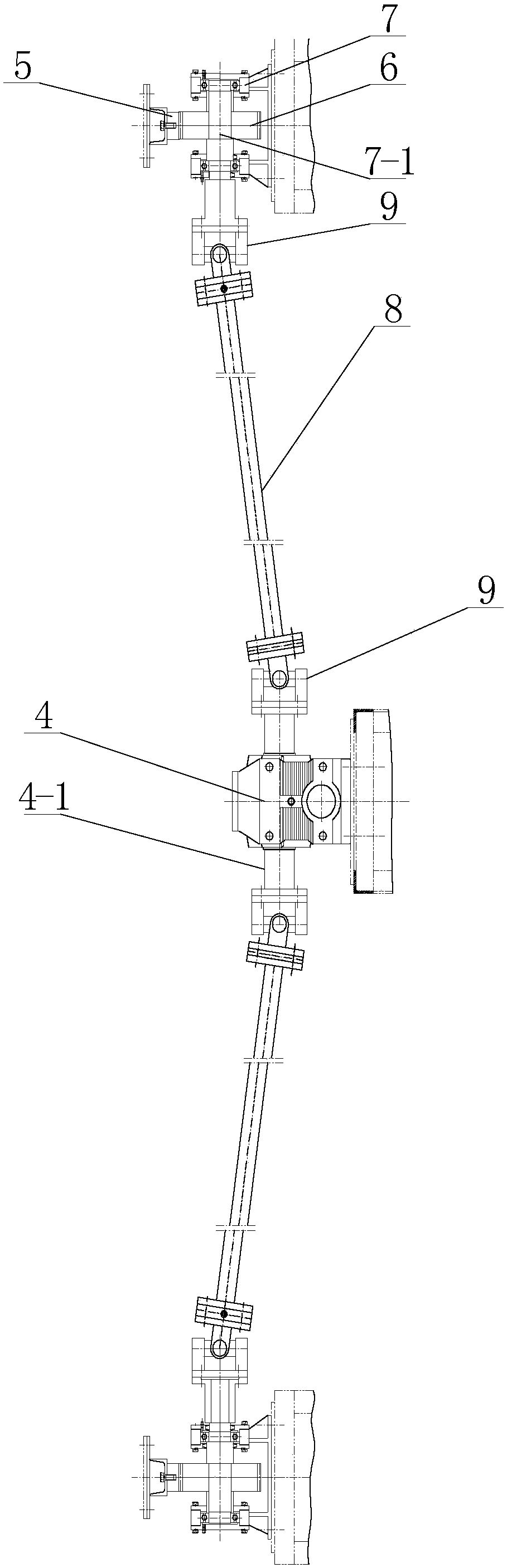

[0016] Specific implementation mode two: combination Figure 1 to Figure 3 To illustrate this embodiment, each of the drive mechanisms of an electric translation roof for an exhaust tower in this embodiment includes a drive motor 3, a gear reducer 4, two racks 5, two gears 6, two Gear base 7 and two transmission components, a rack 5 is respectively installed on the lower surface of each top cover 1, and gear 6 is installed on the gear shaft 7-1 of gear base 7, and gear base 7 is arranged on the bottom of top cover 1, Each gear 6 meshes with a corresponding rack 5 respectively, the rotating shaft of the driving motor 3 is connected with the input shaft of the gear reducer 4, and the two output shafts 4-1 of the gear reducer 4 pass through the two transmission assemblies Connect with the gear shaft 7-1 of two gears 7. The drive motor 3 transmits the power to the two transmission components respectively through the gear reducer 4, and the two transmission components rotate with ...

specific Embodiment approach 3

[0017] Specific implementation mode three: combination Figure 1 to Figure 3 Describe the present embodiment. The electric translational top cover for the exhaust tower described in the present embodiment. Each of the transmission components includes a transmission shaft 8 and two universal joints 9. The output shaft 4-1 of the gear reducer 4 passes through the A universal joint 9 is connected with one end of the transmission shaft 8, and the other end of the transmission shaft 8 is connected with the gear shaft 7-1 of the gear seat 7 through another universal joint 9. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com