Method for preparing antimicrobial material using nano calcium carbonate as substrate

A nano-calcium carbonate, antibacterial material technology, applied in the fields of botanical equipment and methods, fungicides, chemicals for biological control, etc., can solve the problems of narrow adaptability, high preparation cost, low product whiteness, etc. Wide application range, low preparation cost, high whiteness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

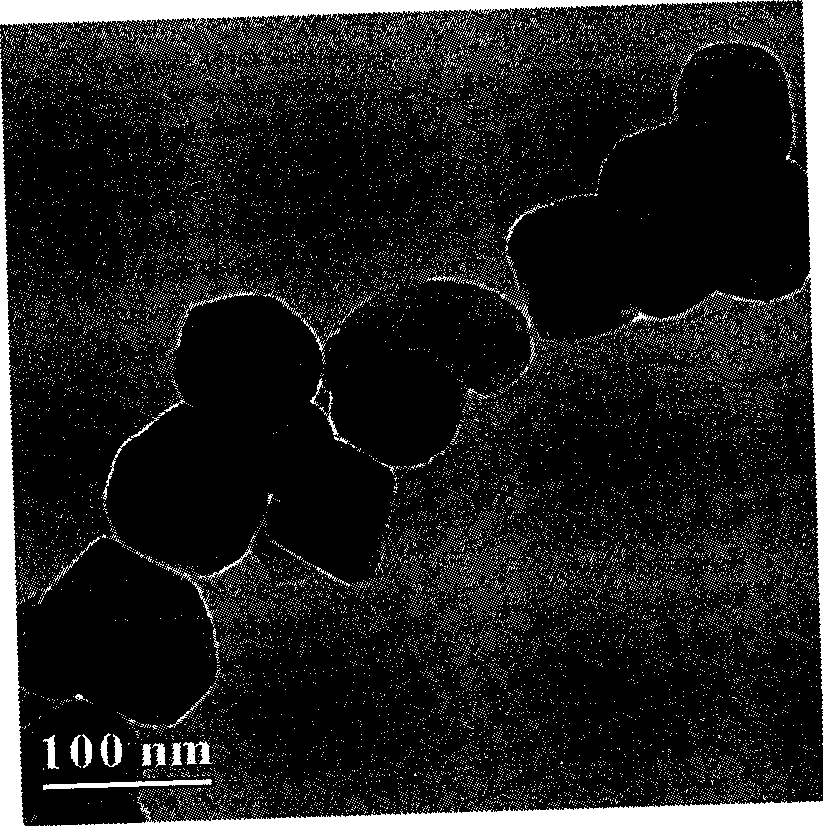

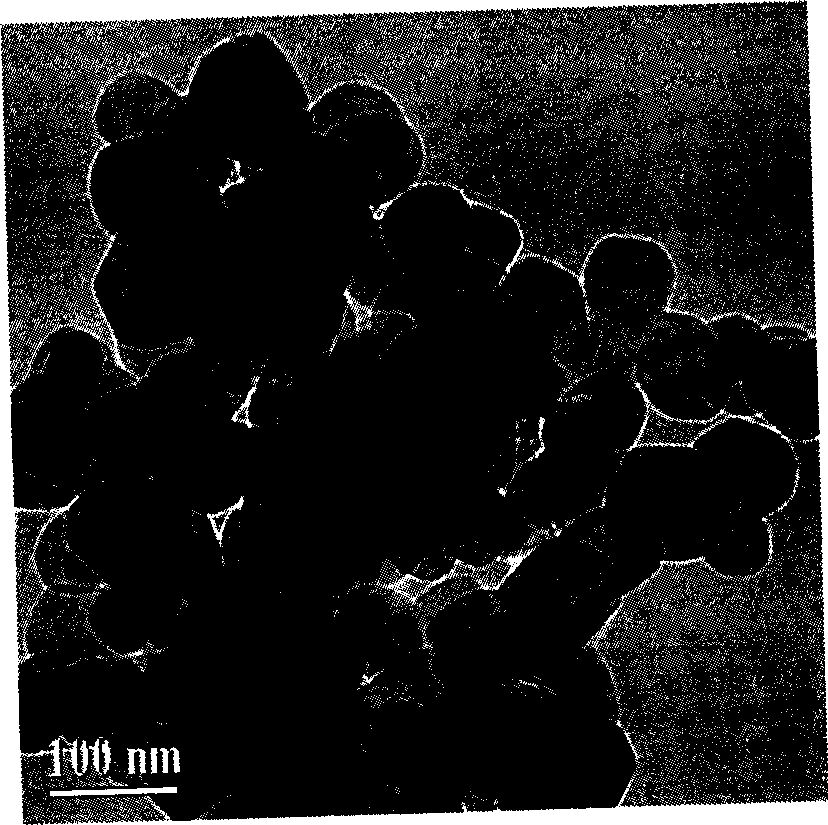

Image

Examples

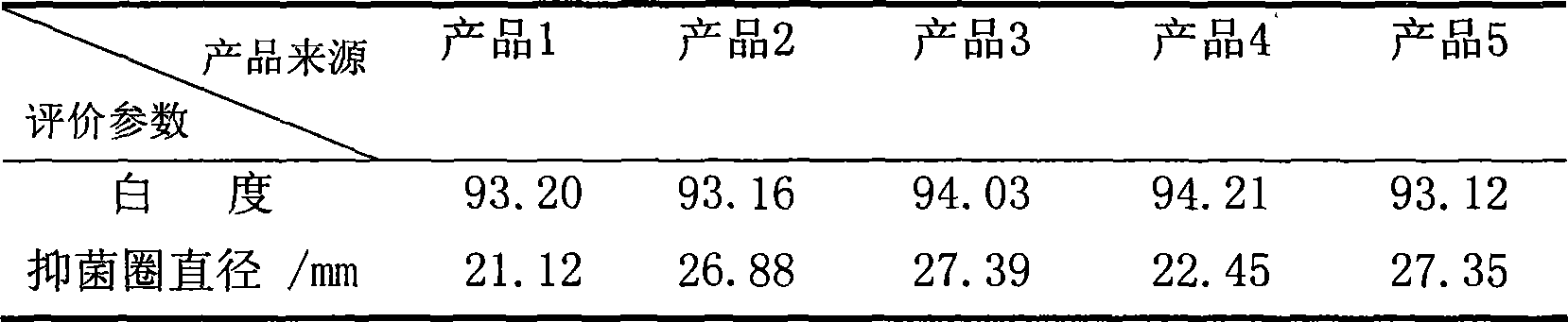

Embodiment 1

[0032] The first step is to prepare nano-calcium carbonate matrix slurry

[0033] At a temperature of 20°C, to the Ca(OH) 2 The mass percent concentration of 0.7mol is 5% Ca(OH) 2 In the slurry, add 0.0175mol of sodium hydroxide, pass into CO 2 , carbonized to the pH=10 of the slurry, thereby preparing the nano-calcium carbonate matrix slurry, which is transferred to a stirred reactor for use;

[0034] The second step is to prepare antibacterial materials with nano-calcium carbonate as the matrix

[0035] Under normal temperature, normal pressure and stirring, add 0.07mol titanium sulfate and 0.0014mol silver nitrate to the nano-calcium carbonate matrix slurry prepared in the first step, finally add phosphoric acid to the pH=7 of the slurry, and carry out suction filtration after 3 hours of reaction, The obtained filter cake was dried at 100° C. to obtain 70 g of product 1 of an antibacterial material with nano-calcium carbonate as a matrix.

Embodiment 2

[0037] The first step is to prepare nano-calcium carbonate matrix slurry

[0038] At a temperature of 25°C, to the Ca(OH) 2 The mass percent concentration of 0.946mol is 7% Ca(OH) 2 In the slurry, add 0.00015mol sodium hexametaphosphate, pass CO 2 , carbonized to the molar ratio M(CaCO 3 ) / M(Ca(OH) 2 )=6:2, make nano-calcium carbonate matrix slurry thus, this slurry is transferred in the reactor with agitation stand-by;

[0039] The second step is to prepare antibacterial materials with nano-calcium carbonate as the matrix

[0040]Under normal temperature, normal pressure and stirring, add the silver nitrate of the titanium nitrate of 0.227mol, the sodium pyrophosphate of 0.0426mol and the silver nitrate of 0.00236mol in the nano-calcium carbonate matrix slurry that the first step makes, after reacting for 3h, carry out suction filtration, will Gained filter cake is dried at 100 ℃, promptly makes the antibacterial material 92g product 2 with nano-calcium carbonate as matr...

Embodiment 3

[0043] The first step is to prepare nano-calcium carbonate matrix slurry

[0044] At a temperature of 15°C, to the Ca(OH) 2 The mass percent concentration of 1.081mol is 8% Ca(OH) 2 In the slurry, add 0.027mol of sodium hydroxide, pass into CO 2 , carbonized to the molar ratio M(CaCO 3 ) / M(Ca(OH) 2 )=5:1, thus making the nano-calcium carbonate matrix slurry, the slurry is transferred to a stirred reactor for use;

[0045] The second step is to prepare antibacterial materials with nano-calcium carbonate as the matrix

[0046] Under normal temperature, normal pressure and stirring, add the sodium silicate of 0.2162mol, the titanium nitrate of 0.0757mol and the silver nitrate of 0.0027mol in the nano calcium carbonate matrix slurry that the first step makes, finally add phosphoric acid to the pH= of slurry 7. After reacting for 4 hours, carry out suction filtration, and dry the resulting filter cake at 100°C to obtain 104g of product 3, an antibacterial material with nano-ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com