Fastener & fastening system

A technology of fasteners and cross-sections, applied in threaded fasteners, connecting components, nails, etc., can solve problems such as complex structures, achieve the effects of firm attachment, improved fastening methods, and increased efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] fastener

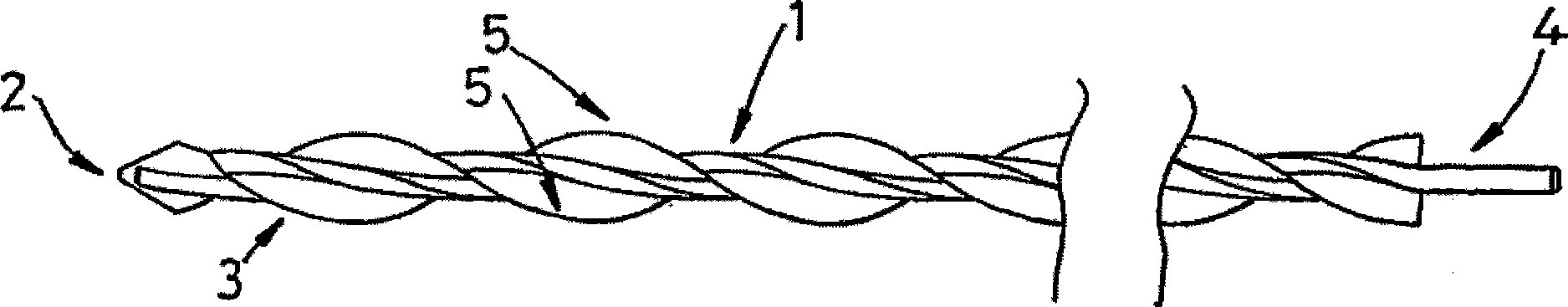

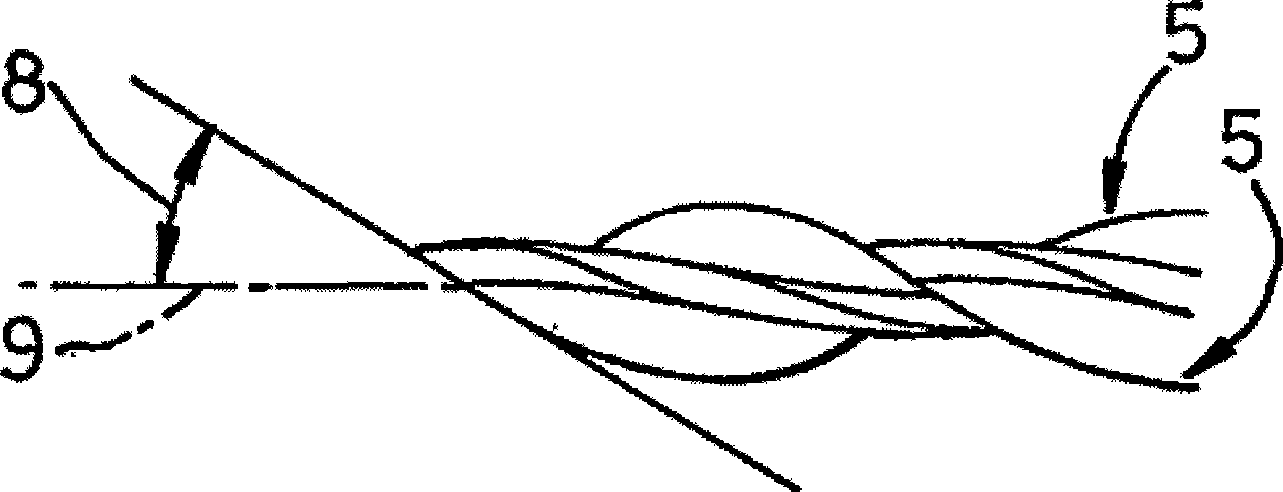

[0039] The typical impact fastener 1 of the present invention has a twisted wire body with a protruding large-radius helix 3 at the forward tip of a substantially conical or frustum of cone 11 and a protruding extension at the rear end. Between long recessed drive shanks 4 with reduced diameter, such as figure 1 shown.

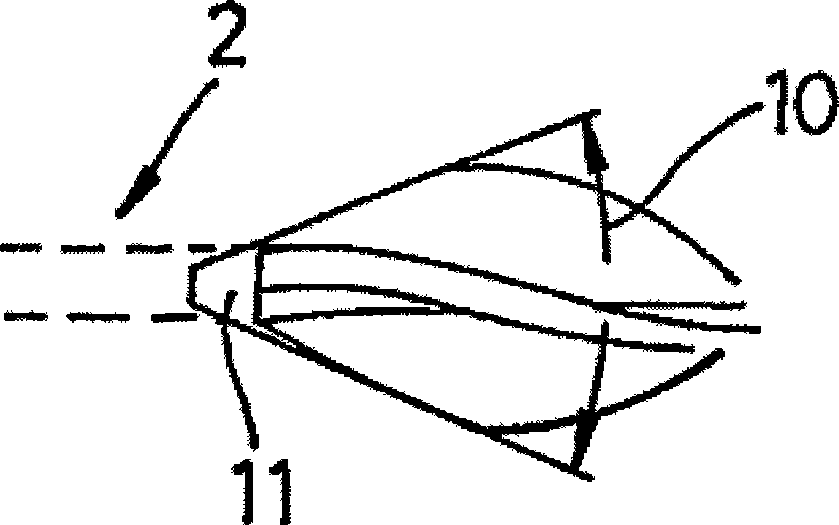

[0040] The torsion body has a solid central axis 2 which is continuous substantially throughout the length of the fastener, said central axis 2 having a maximum cross-sectional diameter at least 7 smaller than the circumscribed circle of the cross-section of said fastener helix. Sixty percent smaller in diameter. Having a torsion body and a relatively small central axis makes the fastener torsionally elastic, allowing it to accommodate small movements between additional layers without affecting the strength of the connection.

[0041] The helical body 3 that forms a taper from the front tip of the fastener has two or three knife-like protr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com