Texturing machine

A deformation machine and machine technology, which is applied in the field of deformation machines, can solve the problems that cannot be adjusted independently, and achieve the effect of improving the effect of thermal barrier, reducing insulation cost and high insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

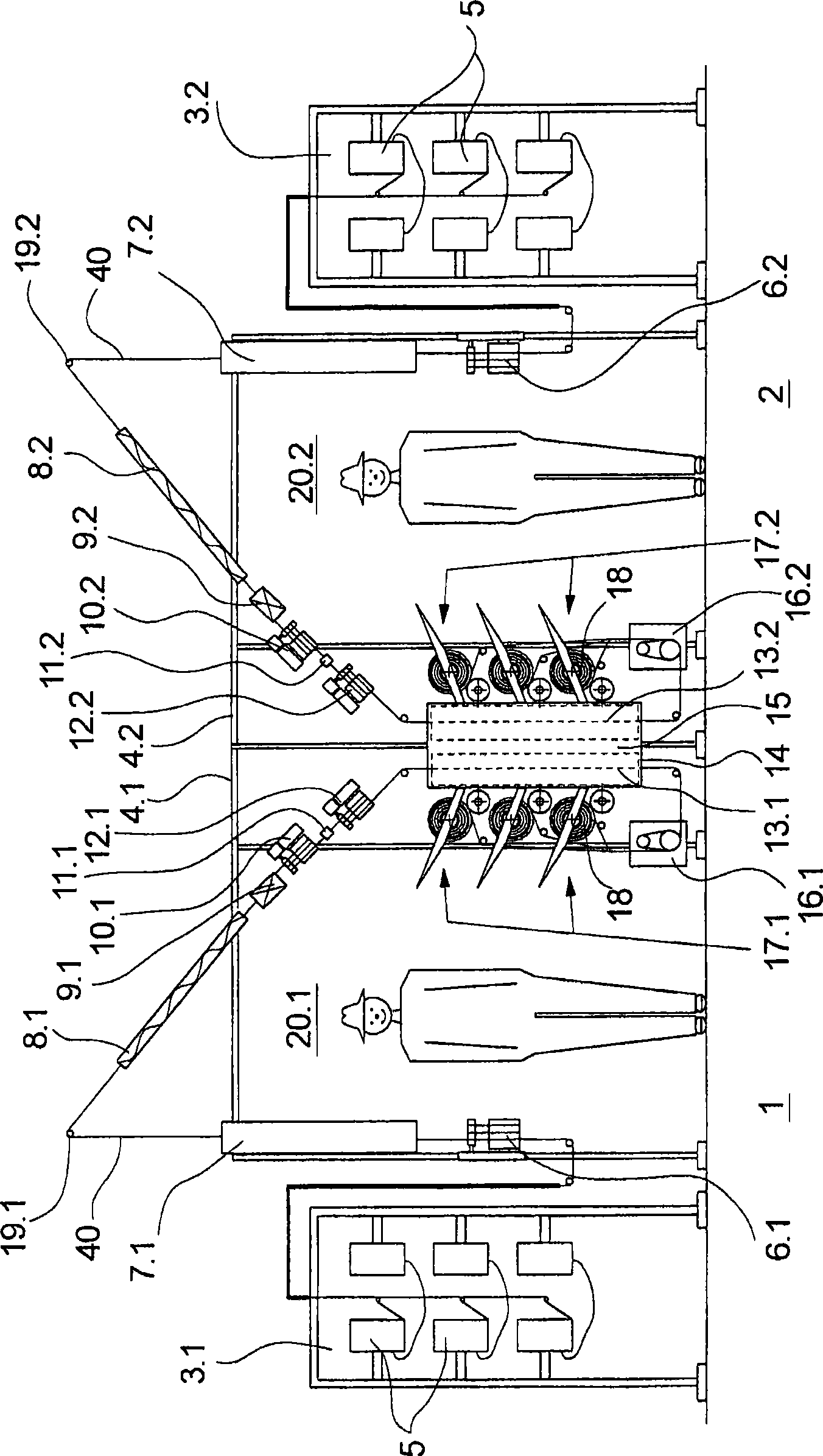

[0024] exist figure 1 The middle diagram shows a cross-sectional view of a first exemplary embodiment of the texturing machine according to the invention. The texturing machine has two mirror-symmetrical machine halves arranged side by side. The left-hand machine half is designated with reference numeral 1 and the right-hand machine half is designated with reference numeral 2 . In the further course of the description, the working units and plant parts assigned to the respective machine half are additionally provided with the reference numeral 1 or 2 to identify the associated machine half.

[0025] Each machine half 1 and 2 comprises a plurality of processing stations in order to deform and wind up one filament in each processing station. exist figure 1 In the view shown in , the filament flow of a processing station is shown in each machine half 1 and 2 . Machine halves 1 and 2 in longitudinal direction—on figure 1 The middle drawing plane is the same as the transverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com