Position returning block assembly machine for automobile combined switch

A combination switch and assembly machine technology, applied in electrical switches, metal processing, electrical components, etc., can solve the problems of inability to meet takt requirements, assembly efficiency and low assembly quality, and achieve the effect of improving quality and efficiency and meeting takt requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

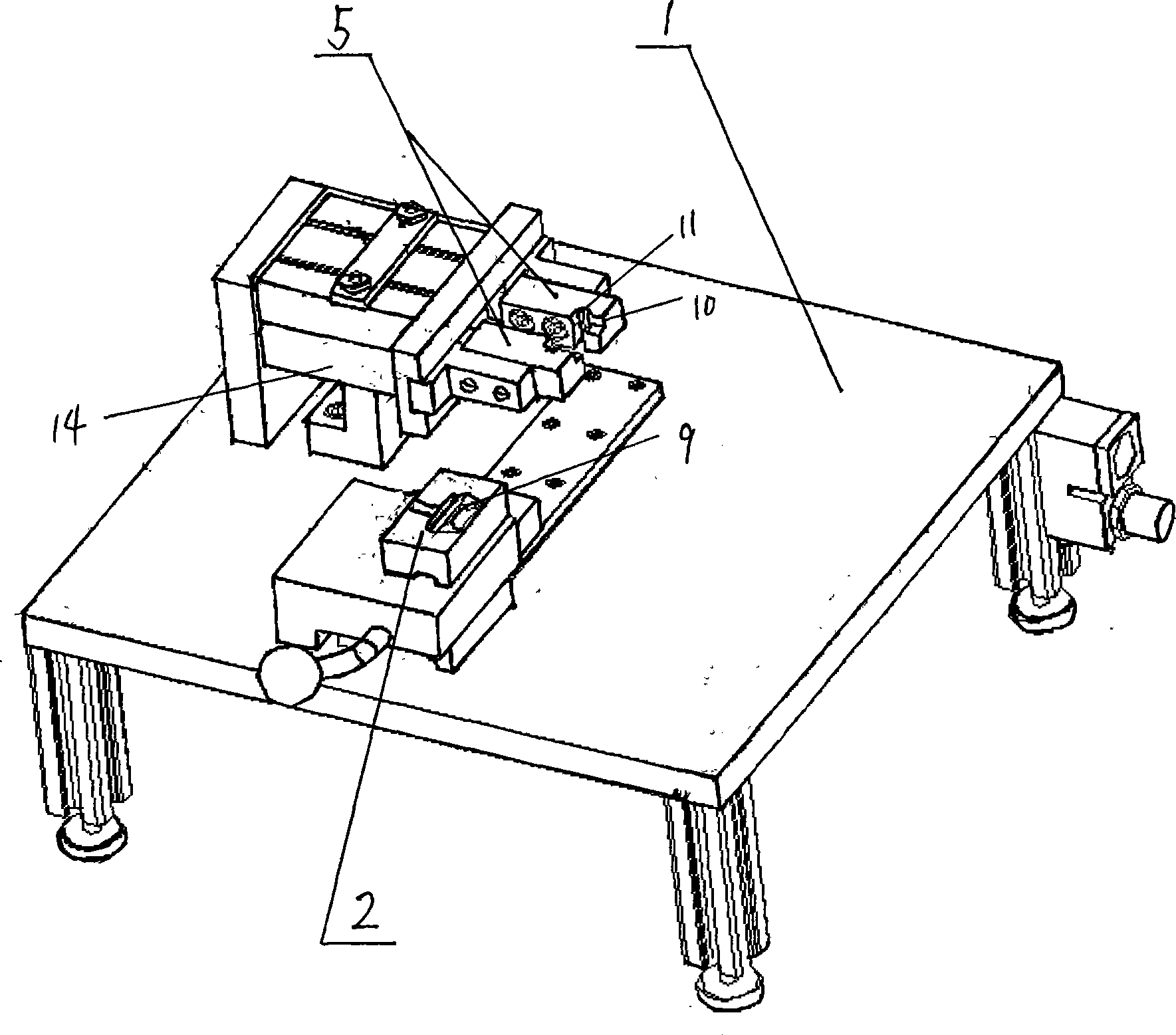

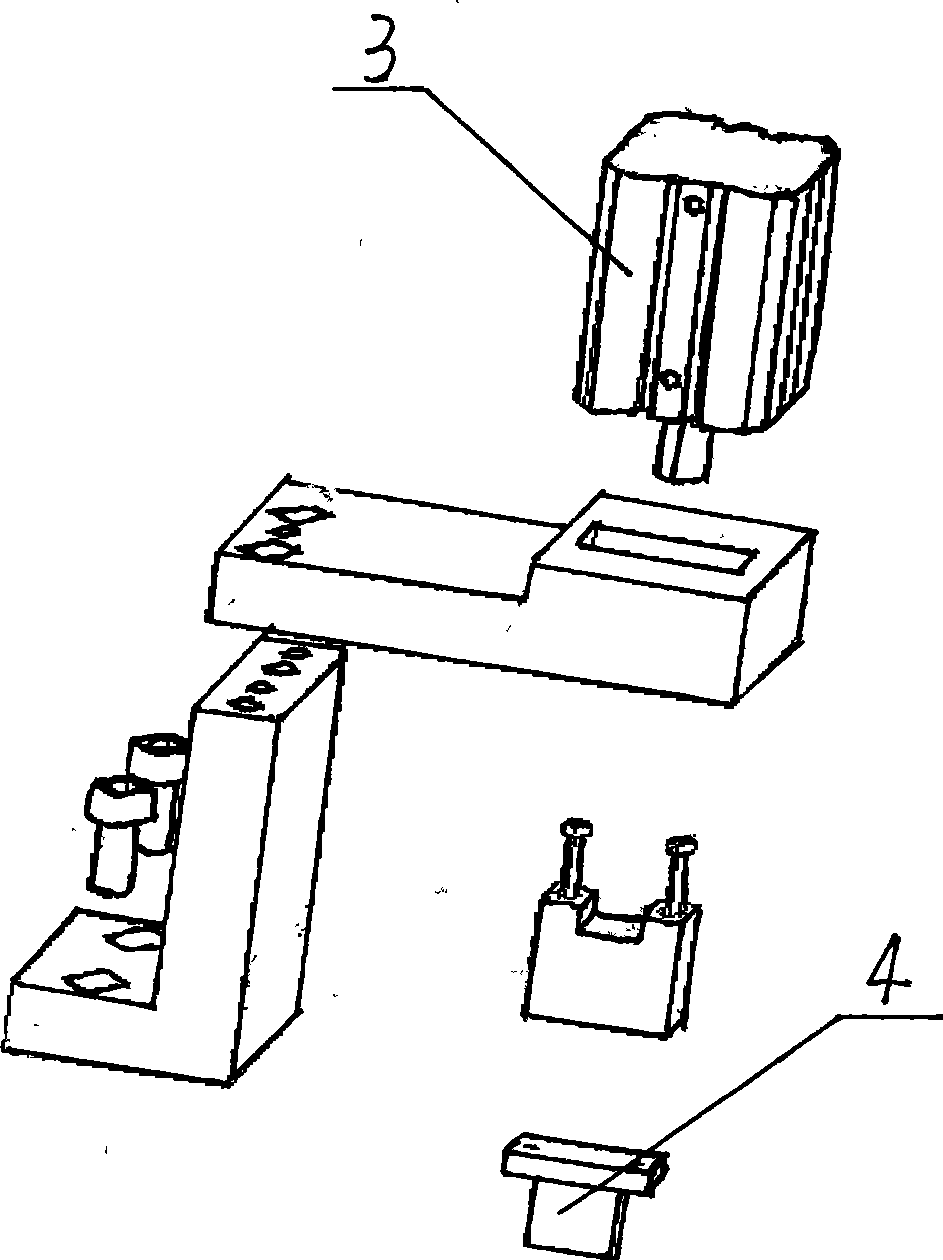

[0012] see figure 1 , figure 2 , image 3 , the car combination switch homing block assembly machine includes a stand 1, a slider that slides forward and backward in a straight line is installed on the bench 1, a homing block fixture 2 is installed on the slider, and a homing block fixture 2 is provided with a homing block. Positioning block accommodating groove 9; a stamping mechanism is installed above the homing block fixture 2, and the stamping mechanism is composed of a down-press cylinder 3 installed on the homing block fixture 2 and a punch 4 fixedly connected to the lower end of the down-press cylinder 3 piston rod; The left and right sides of the homing block fixture 2 are respectively equipped with an air claw compression mechanism and a spring feeding mechanism; the air claw compression mechanism includes two horizontal clamping blocks 5; the front end of the clamping block 5 has a bayonet 10 for accommodating springs, The rear end of the bayonet socket 10 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com