Body pressing device for transformer

A compression device and transformer technology, applied in the direction of transformer/inductor coil/winding/connection, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of transformer coil deformation, transformer accidents, elastic buffering of the device body, etc. , to save maintenance costs, protect safety, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

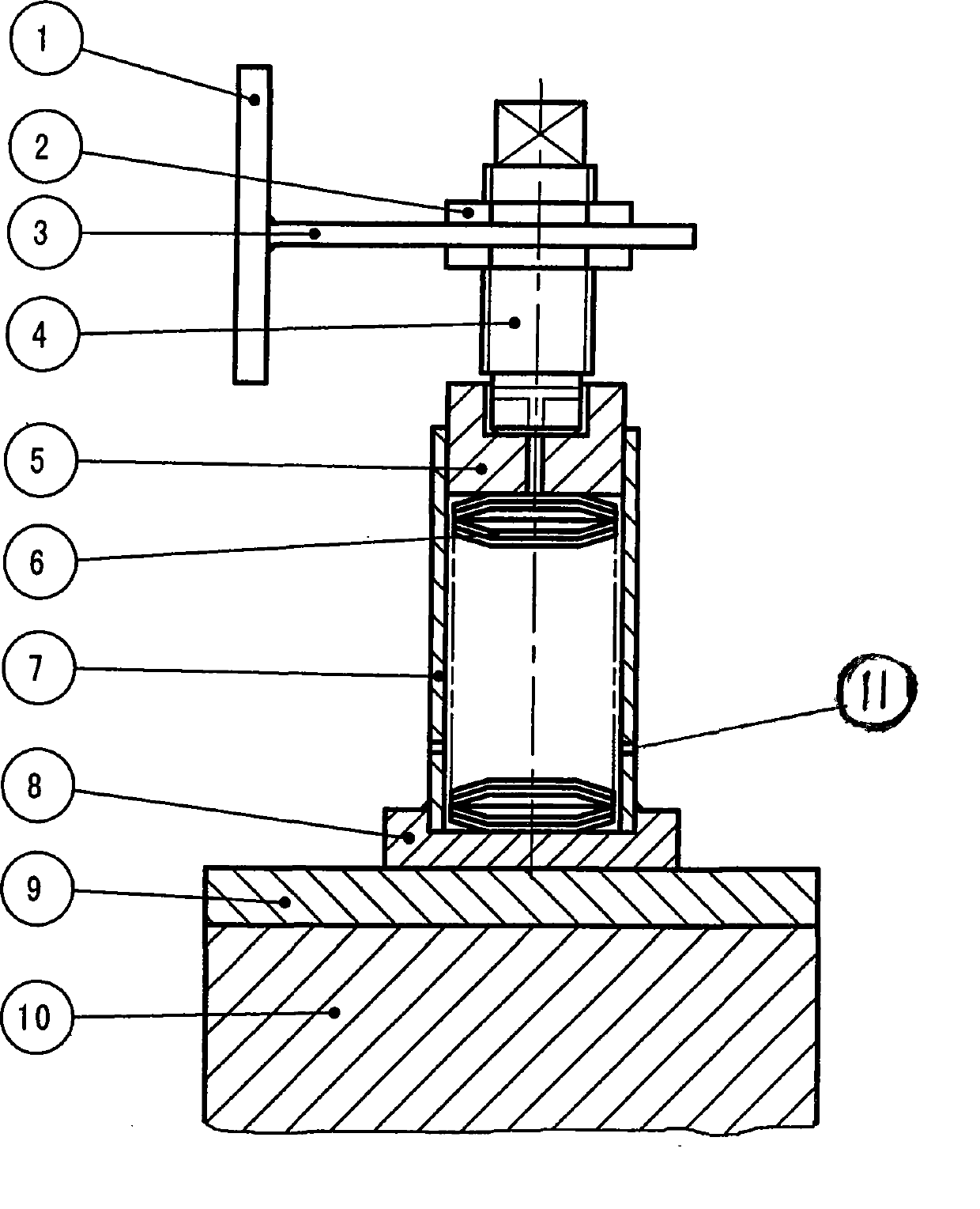

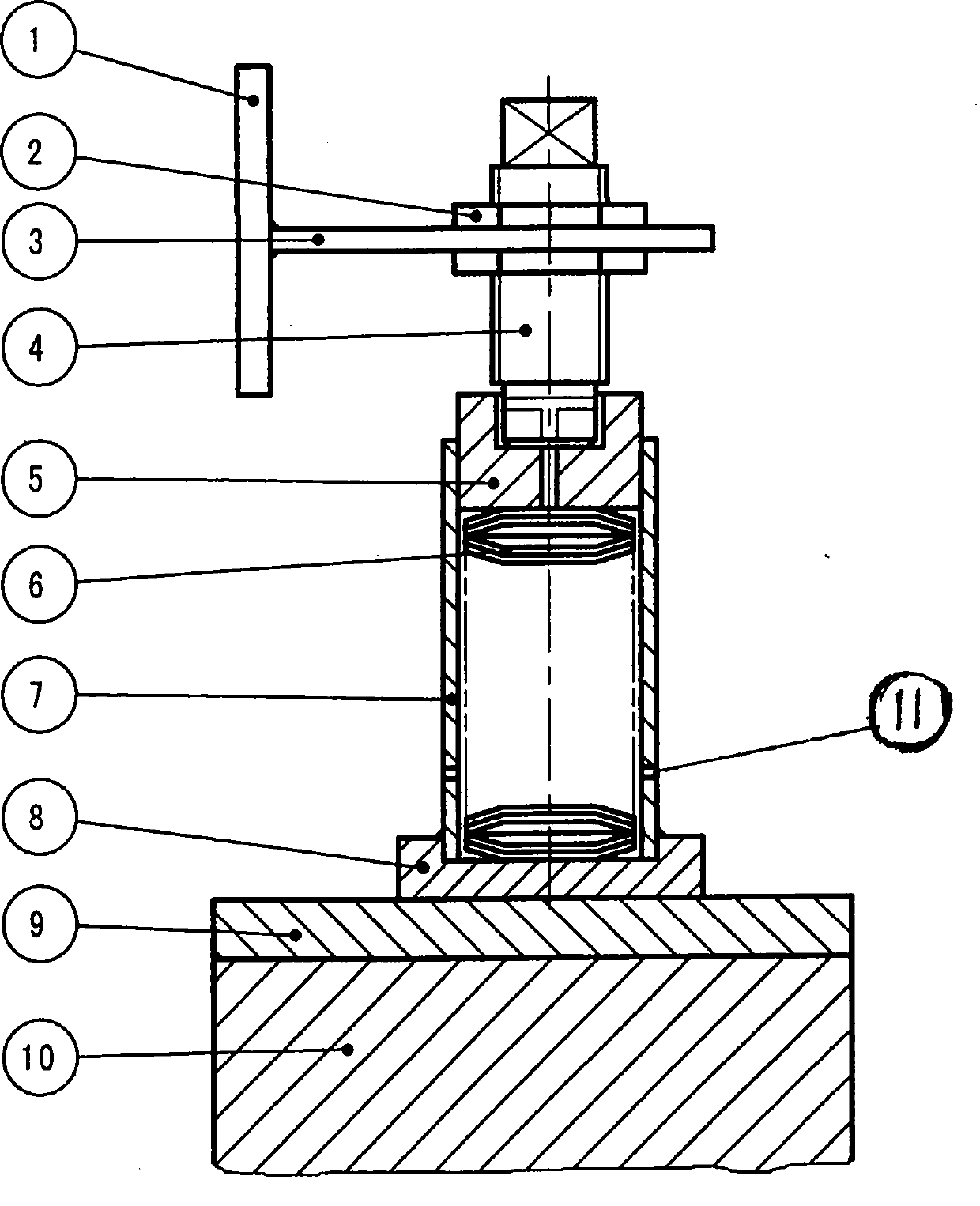

[0009] The present invention mainly consists of the coil pressing plate 9 placed on the upper part of the coil 10 and the iron core upper clamp 1, the washer 8 placed on the coil pressing plate 9 with the briquetting sleeve 7, the butterfly spring 6 and the pressing piece placed in the briquetting sleeve 7. Block 5, which is placed on the top of the pressing block 5 and consists of a compression screw 4 with a nut 2 and a connector 3; one end of the connector 3 is welded and fixed on the iron core upper clamp 1.

[0010] After the transformer is assembled, use a wrench to rotate the compression screw 4, so that the compression screw 4 and the compression block 5 move downward, adjust the compression degree with the coil pressure plate 9, and then use the wrench to tighten the two compression nuts 2 The compression screw 4 is locked on the upper and lower sides of the connecting plate 3 to prevent the compression screw 4 from loosening due to vibration during transportation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com