Experimental device for restraining gas and dust explosion by water mist

A dust explosion and experimental device technology, applied in the field of safety science and engineering experimental equipment, can solve the problems of reducing the pressure and energy of the explosion gas, and cannot fundamentally suppress the explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

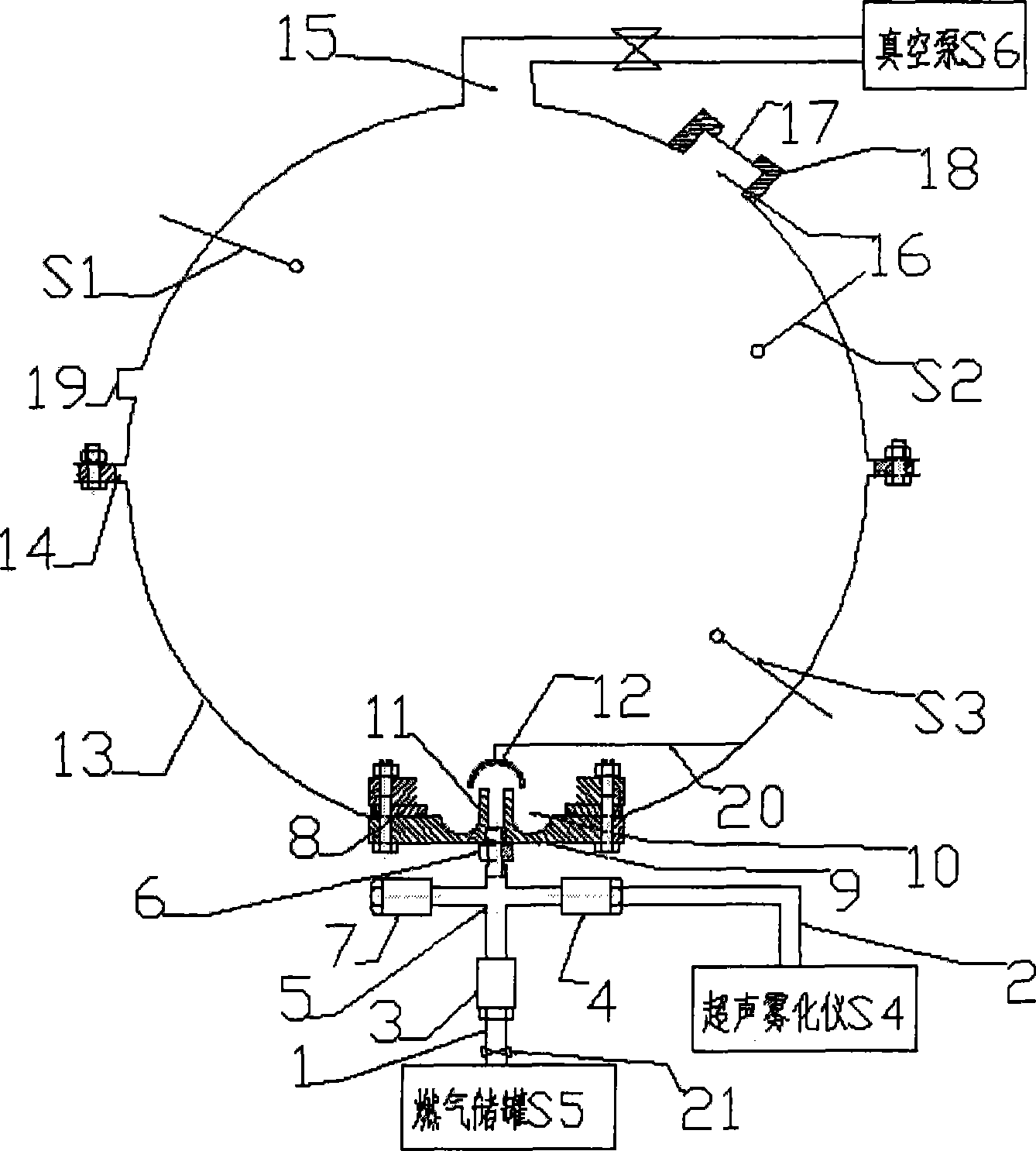

[0015] In this embodiment, the spherical burner experimental device that uses fine water mist to suppress gas and dust explosions is as follows: figure 1 As shown: the burner 13 is composed of upper and lower stainless steel hollow hemispheres fixed and sealed with bolts and rubber gaskets. A transparent tempered glass observation window 19 is provided on the upper part of the wall near the hemispherical joint 14. The top of the burner There is an air extraction hole 15 connected to the vacuum pump S6 through an air extraction valve; a pressure relief hole 16 is provided on the wall near the air extraction hole 15, and a nut 18 with a hole is used to seal and press the explosion-proof plate 17 to the pressure relief hole On the bolts, once overpressure, the explosion-proof disk will automatically rupture to achieve safe pressure relief, so as to avoid the device being damaged due to excessive pressure in the experiment; there are pressure sensor S1 and temperature sensor S2 bui...

Embodiment 2

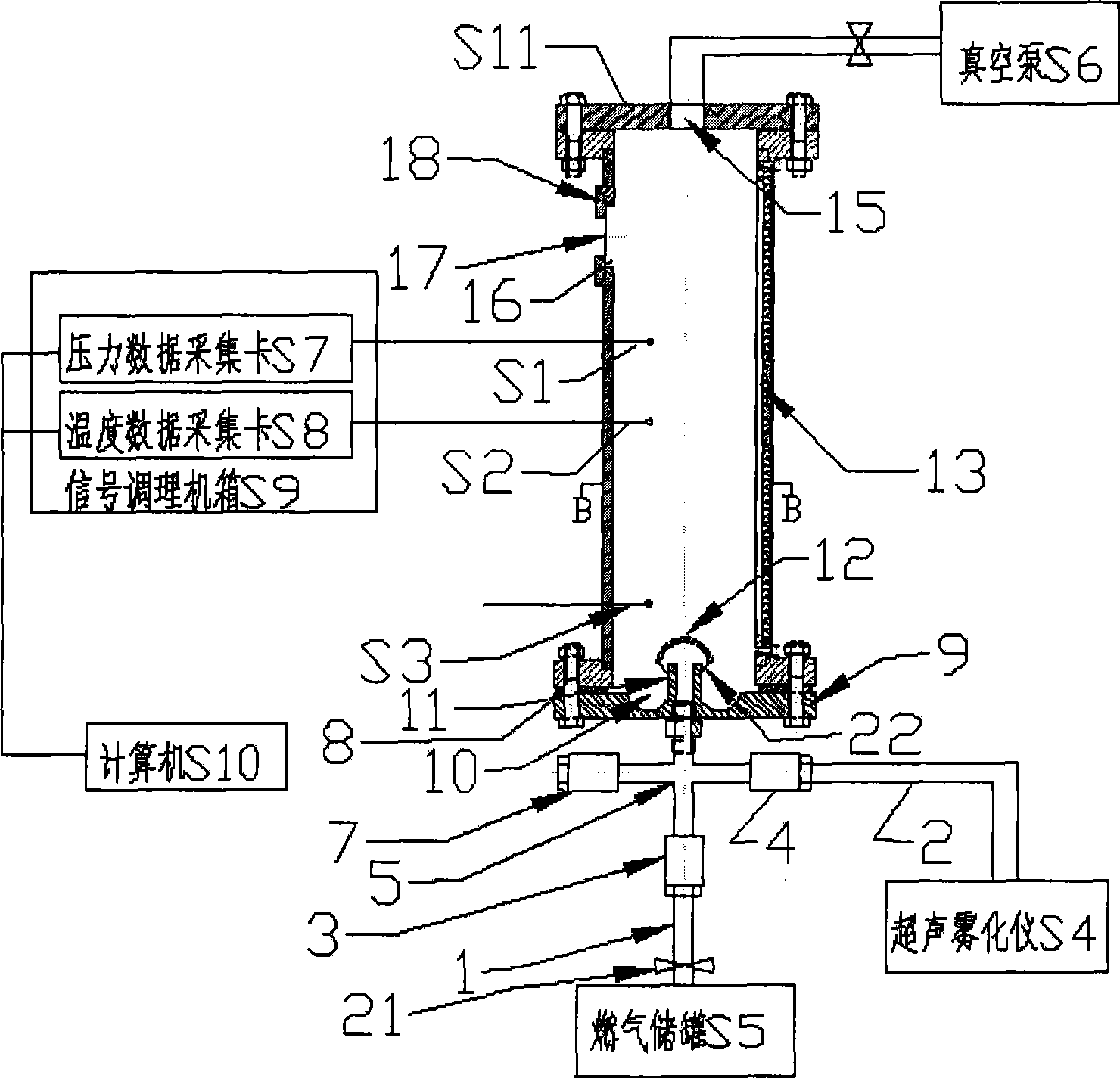

[0021] figure 2 It is a schematic diagram of the structure of a rectangular column burner experimental device using fine water mist to suppress gas and dust explosions in this embodiment. One wall of the burner 13 is made of stainless steel, and the other three walls are made of transparent tempered glass. According to the theory of combustion and explosion, and considering the precipitation of dust under the action of gravity, in order to make the dust can fill the burner, the length-to-diameter ratio of the burner can be 1:6, and the rectangular column burner of this embodiment can be calculated accordingly equivalent size.

[0022] In the center of the top flange S11 of the burner 13, there is an air extraction hole 15 connected to the vacuum pump S6. An air extraction valve is provided on the pipeline between the air extraction hole 15 and the vacuum pump S6. Rubber is used between the top flange S11 and the wall of the burner. The gasket is sealed and fixed with bolts, an...

Embodiment 3

[0027] In this embodiment, an experimental device for suppressing gas and dust explosions by fine water mist is used. The burner is a stainless steel cylinder, and a transparent observation window is provided in the middle of the wall of the burner. A high-speed camera was used to take pictures of the experimental phenomena in the observation window. The gas is liquefied gas, the dust is wheat starch, and the ignition device is an electric spark igniter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com