Child-preventing security igniting gun

A kind of ignition gun and child-proof technology, applied in the field of ignition guns, can solve the problems of unbalanced force on the cross rod, poor ignition reliability, false ignition, etc., and achieve the effect of simple and compact structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

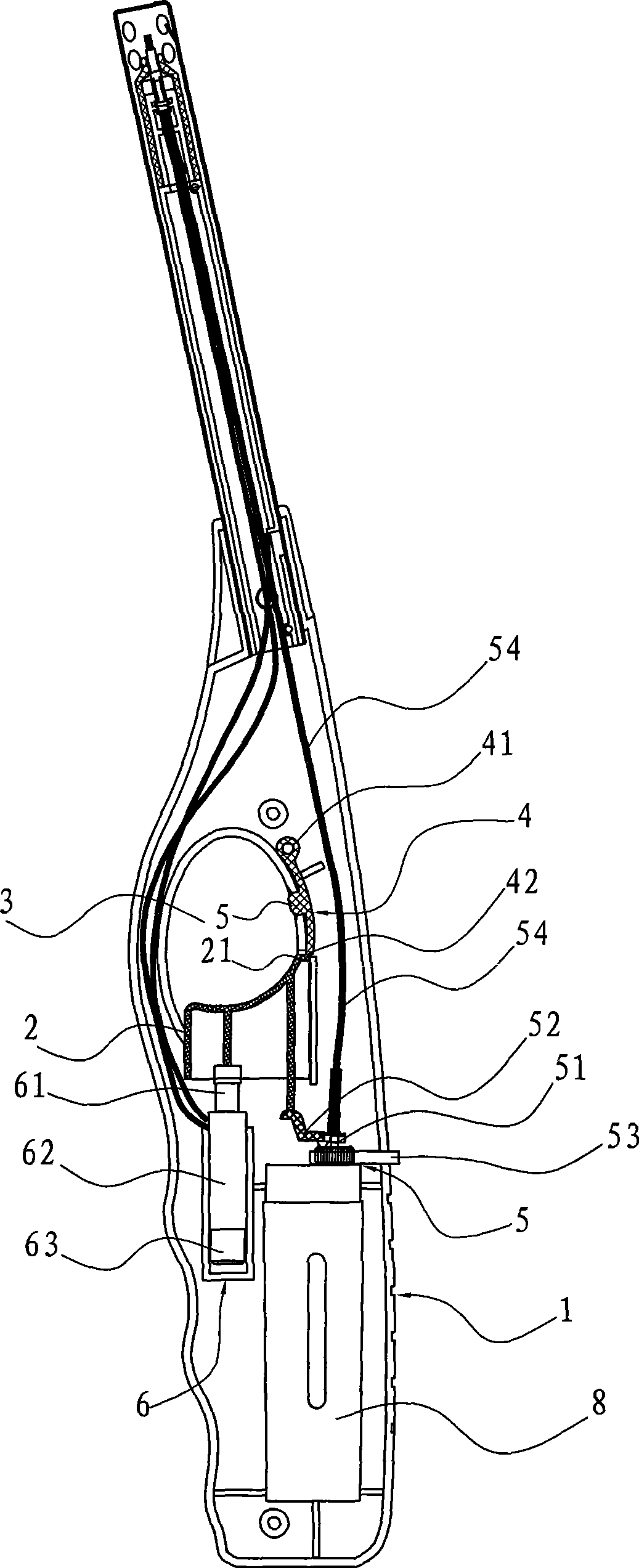

[0031] Such as Figure 1~3 As shown, the ignition gun includes a handle 1 that can be held and an ignition barrel that extends outwards. The handle 1 and the ignition barrel in this embodiment have substantially the same shape and are integrated. Box 8 and its gas valve device 5 and piezoelectric ignition device 6, wherein the gas valve device 5 includes a gas outlet needle 51 and a rocker 52 connected to the gas outlet needle 51 at one end, and the gas is sent through the gas delivery hose 54 connected to the gas outlet needle 51. To the nozzle of the ignition gun, the piezoelectric ignition device 6 includes a piezoelectric cap 61, a piezoelectric body 62 and a piezoelectric copper anvil 63, which are used to generate voltage and cause a discharge spark at the nozzle of the ignition gun through a wire; There is an adjusting button 53 for adjusting the size of the fire pit;

[0032] The ignition trigger 2 is arranged on the abdomen of the handle 1, and partly exposed outside...

Embodiment 2

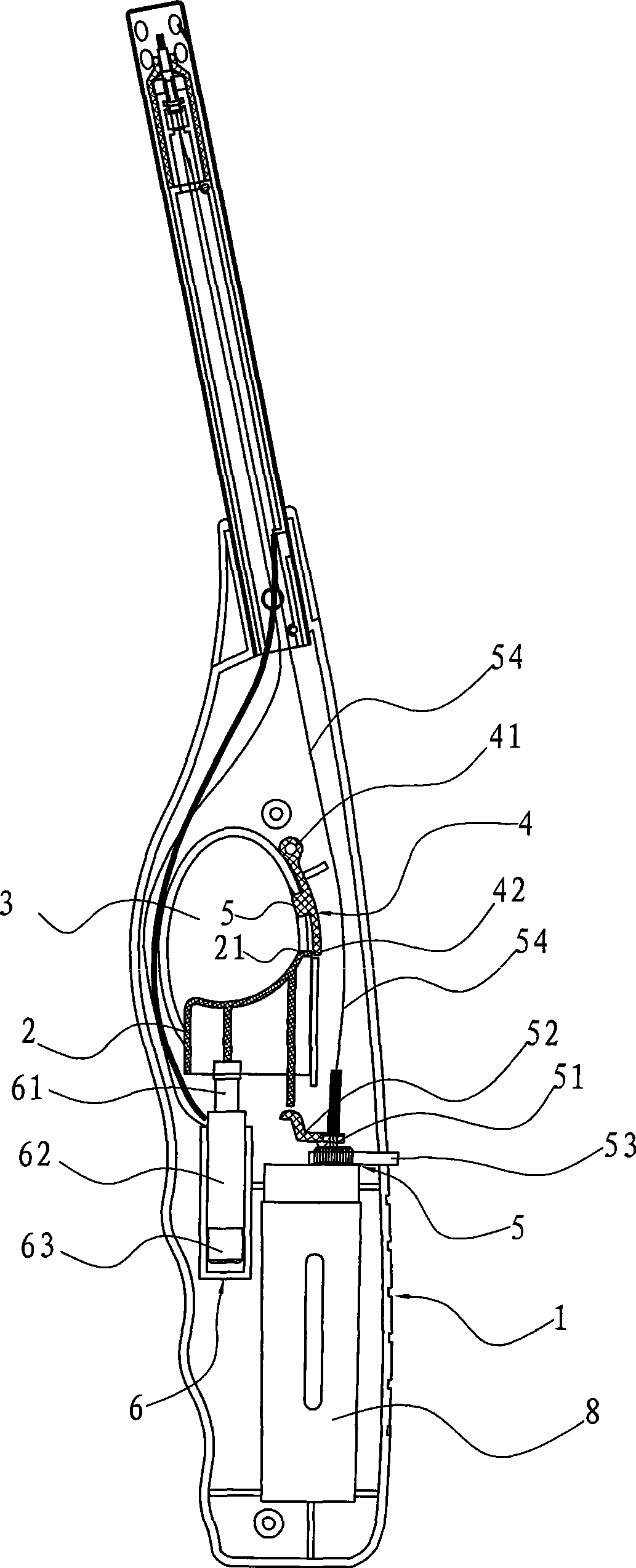

[0038] Such as Figure 4 As shown, the difference from Example 1 is that see Figure 4 As shown, the above-mentioned resettable blocking member 4 is arranged below the ignition trigger 2, and the lower end of the ignition trigger 2 is provided with a limit protrusion 22, which is reset under the reset mechanism of the piezoelectric device after the ignition trigger is used for ignition. At this time, the free end of the elastic member 4 is in contact with the limit protrusion 221 at the lower end of the ignition trigger 2 under the action of its own elastic force, so that the ignition trigger 2 cannot be completely reset automatically.

[0039] And safety switch 5 is arranged on below the middle part cavity of the handle, and part is exposed to the cavity below the middle part of the handle.

[0040] Its working principle is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

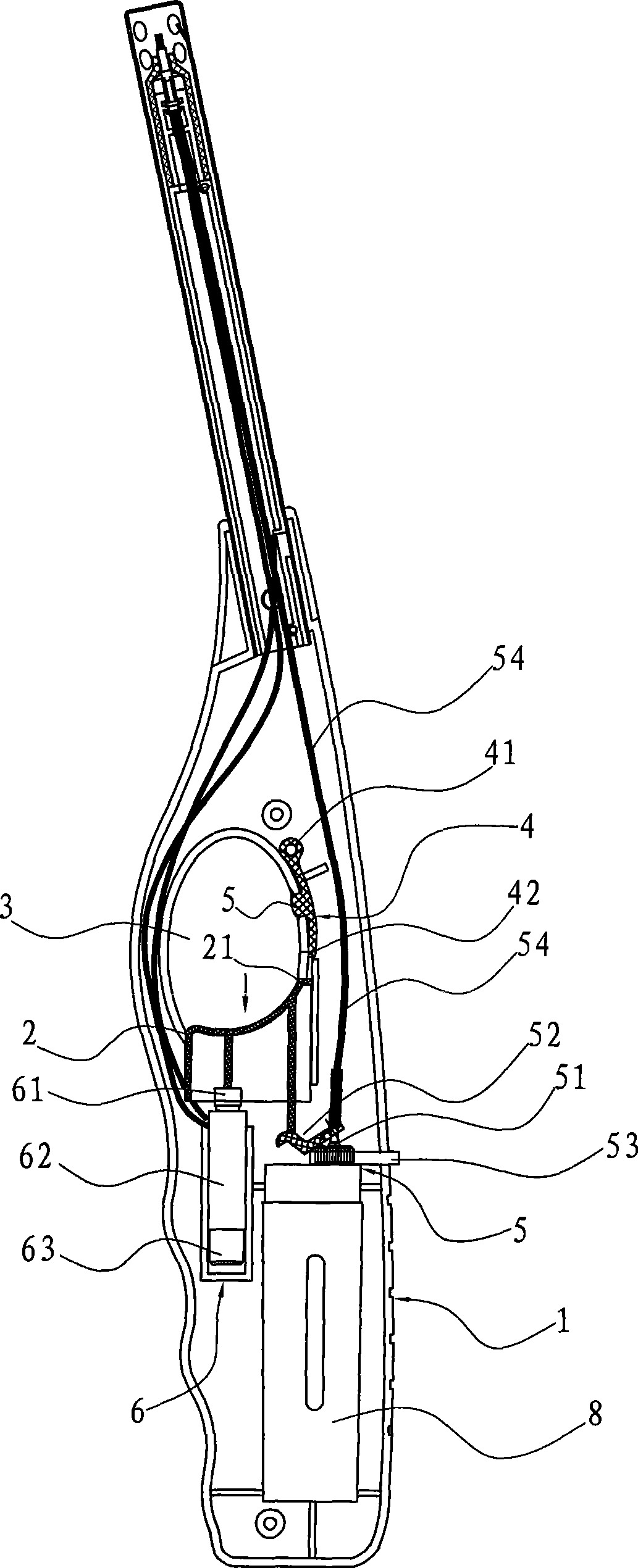

[0042] Different from Embodiment 1, the resettable blocking member 4 is not an integral elastic member, but a part of the elastic member, which includes a limiting member 4a and an elastic reset member 4b, see Figure 5 As shown, and the limiting part 4a and the elastic reset part 4b are one piece, the elastic restoring part 4b is made of an elastic sheet, the first end of the elastic restoring part 4b is connected with the free end 412 of the limiting part 4a, and the elastic restoring part The second end of 4b is against the inner wall of the handle, and forces the limiting member 4a to have a tendency to move downward relative to the ignition trigger; one end 411 of the limiting member 4a is rotatably arranged in the handle, and the other free end 412 is in the reset state and is in contact with the ignition trigger. The upper end of trigger 2 is offset. Its working principle is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com