Thermal coupling apparatus and process for alcohol differential pressure distillation and waste liquor concentrate of molasses raw material

A technology of thermal coupling and raw materials, which is applied in the field of alcohol differential pressure distillation and waste liquid evaporation and concentration, can solve the problems of unfavorable combined device process smooth operation, difficult process control, complicated equipment manufacturing, etc., to save cooling water consumption, steam Consumption saving and steam consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

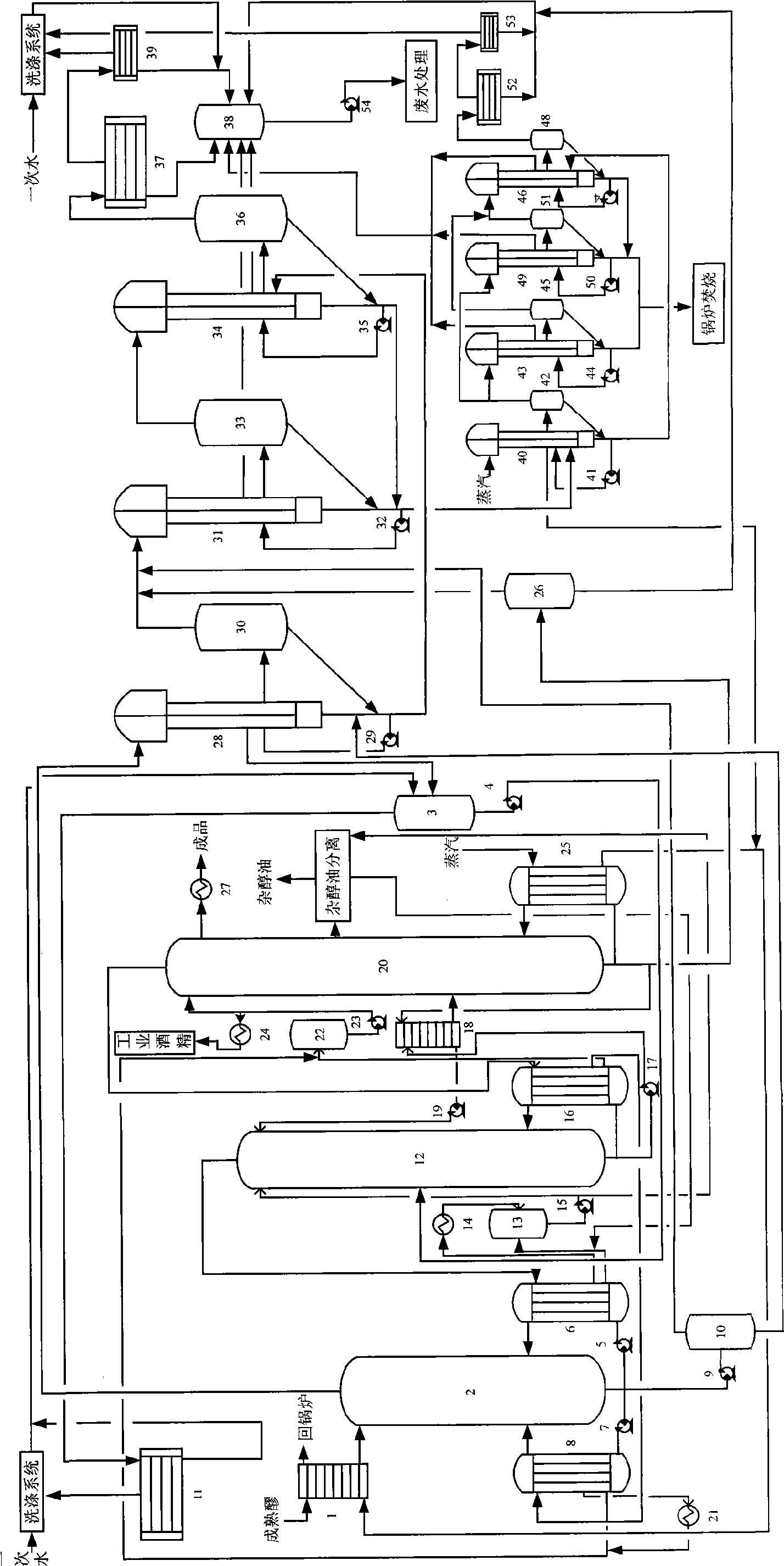

[0038] as attached figure 1 As shown, an alcohol differential pressure distillation and waste liquid treatment device using molasses as a raw material is provided with a crude distillation column 2, a water washing column 12, a rectification column 20, a first-stage first-effect evaporator 28, and a first-stage second-effect evaporator 31 , a first-stage three-effect evaporator 34, a second-stage first-effect evaporator 40, a second-stage second-effect evaporator 43, a second-stage three-effect evaporator 46 and a second-stage four-effect evaporator 49. Wherein the top outlet of the rectifying tower 20 is connected to the shell side inlet of the reboiler 16 of the water washing tower through a pipeline, and the shell side of the reboiler 16 of the water washing tower is provided with two outlets, wherein the vapor phase outlet of the shell side is connected to the second crude distillation tower through a pipeline. The shell side inlet of the boiler 8 is connected, the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com