Antistatic powder for antistatic ceramic tile

An anti-static powder and ceramic tile technology, applied in the field of architectural ceramics, can solve the problems of high dust emission index, limited application of clean workshops, poor durability and fire resistance, etc. The effect of stable electrostatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

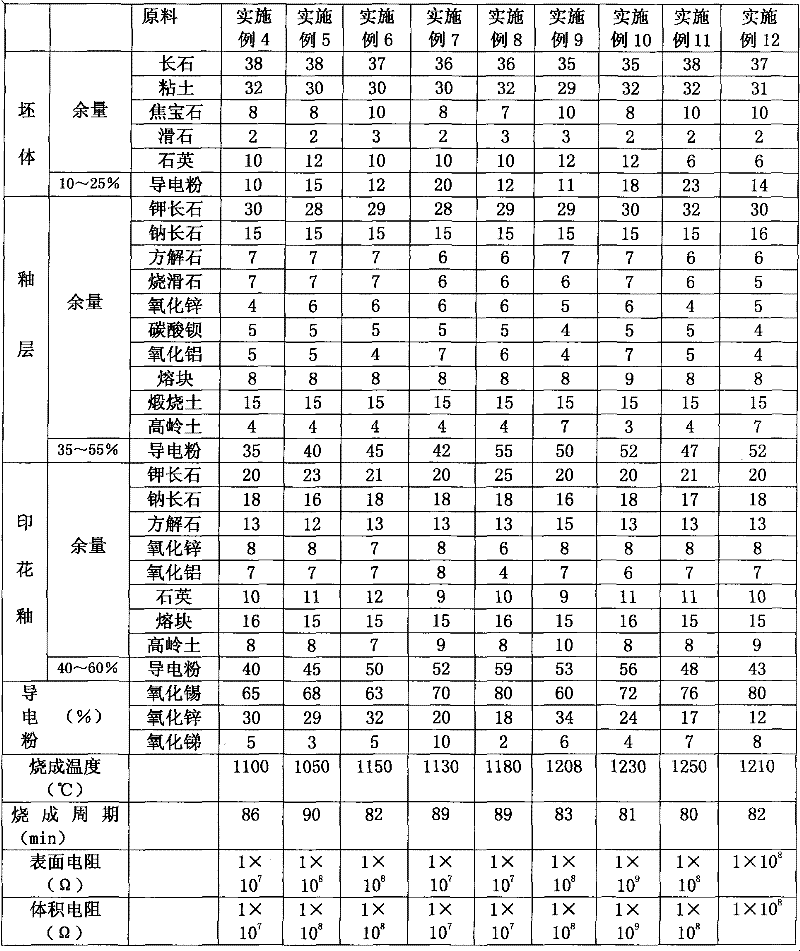

Examples

Embodiment 1

[0028] Embodiment 1, the making of antistatic pottery brick.

[0029] The mass percentage of the conductive powder is composed of: 70% of tin oxide, 15% of zinc oxide and the balance of antimony oxide.

[0030] 1.1 Blank preparation:

[0031] 1.1.1 11% antistatic powder for antistatic ceramic tiles, 89% raw materials for ordinary ceramic tiles (calculated by dry weight)

[0032] 1.1.2 Put it in the mud pool and add an appropriate amount of water to mix it evenly, and let it stale for 13 hours.

[0033] 1.1.3 Pass the mud through an 80-mesh vibrating sieve, and make powder through a spray drying tower.

[0034] 1.1.4 Compression forming.

[0035] 1.2 Glaze preparation:

[0036] 1.2.145% antistatic powder for antistatic ceramic tiles, 55% by weight of ordinary glaze, put into a ball mill for grinding.

[0037] 1.2.2 Grind the glaze slurry to a fineness of 0.5% / 100ml, and use a 325 sieve.

[0038] 1.2.3 Pass through a 120-mesh vibrating sieve and put it into a tank for late...

Embodiment 2

[0048] Embodiment 2, the making of antistatic fine stoneware brick.

[0049] The mass percentage of the conductive powder is composed of: 75% of tin oxide, 20% of zinc oxide and the balance of antimony oxide.

[0050] 2.1 Blank preparation:

[0051] 2.1.1 15% antistatic powder for antistatic ceramic tiles, 85% raw materials for ceramic fine stoneware bricks (calculated by dry weight)

[0052] 2.1.2 Put it in the mud pool and add an appropriate amount of water to mix it evenly, and let it stale for 14 hours.

[0053] 2.1.3 Pass the mud through an 80-mesh vibrating sieve, and make powder through a spray drying tower.

[0054] 2.1.4 Compression molding.

[0055] 2.2 Glaze preparation:

[0056] 2.2.150% antistatic powder for antistatic ceramic tiles, 50% by weight of ordinary glaze, put into a ball mill for grinding.

[0057] 2.2.2 Grind the glaze slurry to a fineness of 0.7% / 100ml, and use a 325 sieve.

[0058] 2.2.3 Pass through a 120-mesh vibrating sieve and put it into a...

Embodiment 3

[0068] Embodiment 3, the making of antistatic porcelain tile.

[0069] The mass percentage of the conductive powder is composed of: 62% of tin oxide, 16% of zinc oxide and the balance of antimony oxide.

[0070] 3.1 Blank preparation:

[0071] 3.1.1 15% antistatic powder for antistatic ceramic tiles, 85% raw materials for porcelain tile body (calculated by weight of dry material)

[0072] 3.1.2 Put it in the mud pool and add an appropriate amount of water to mix it evenly, and let it stale for 13 hours.

[0073] 3.1.3 Pass the mud through an 80-mesh vibrating sieve, and make powder through a spray drying tower.

[0074] 3.1.4 Compression molding.

[0075] 3.2 Glaze preparation:

[0076] 3.2.1 53% antistatic powder of antistatic ceramic tiles, 47% by weight of ordinary glaze, put into a ball mill for grinding.

[0077] 3.2.2 Grind the glaze slurry to a fineness of 0.7% / 100ml, and use a 325 sieve.

[0078] 3.2.3 Pass through a 120-mesh vibrating sieve and put it into a tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com