Catalyst for purifying exhaust of petrol engine using ethyl hydrate as fuel and preparation method thereof

A technology for tail gas purification and ethanol fuel, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high temperature deactivation of transition metal catalysts, and achieve improved thermal stability and low temperature activity, High removal efficiency, promoting improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh Ce(NO 3 ) 3 6H 2 O 27.342g, ZrO(NO 3 ) 2 6H 2 O 8.667g, Mn(NO 3 ) 2 3.579g was made into 200ml solution, 50.4336g of citric acid was weighed to make 1548ml solution, after mixing evenly, 30ml of ethylene glycol was added, stirred at room temperature for 30min, heated in 80°C water bath for 12h, wet gel was dried at 100°C for 8 hours, milled, Calcined at 500°C for 5 hours to obtain CeO 2 —ZrO 2 - MnOx catalyst.

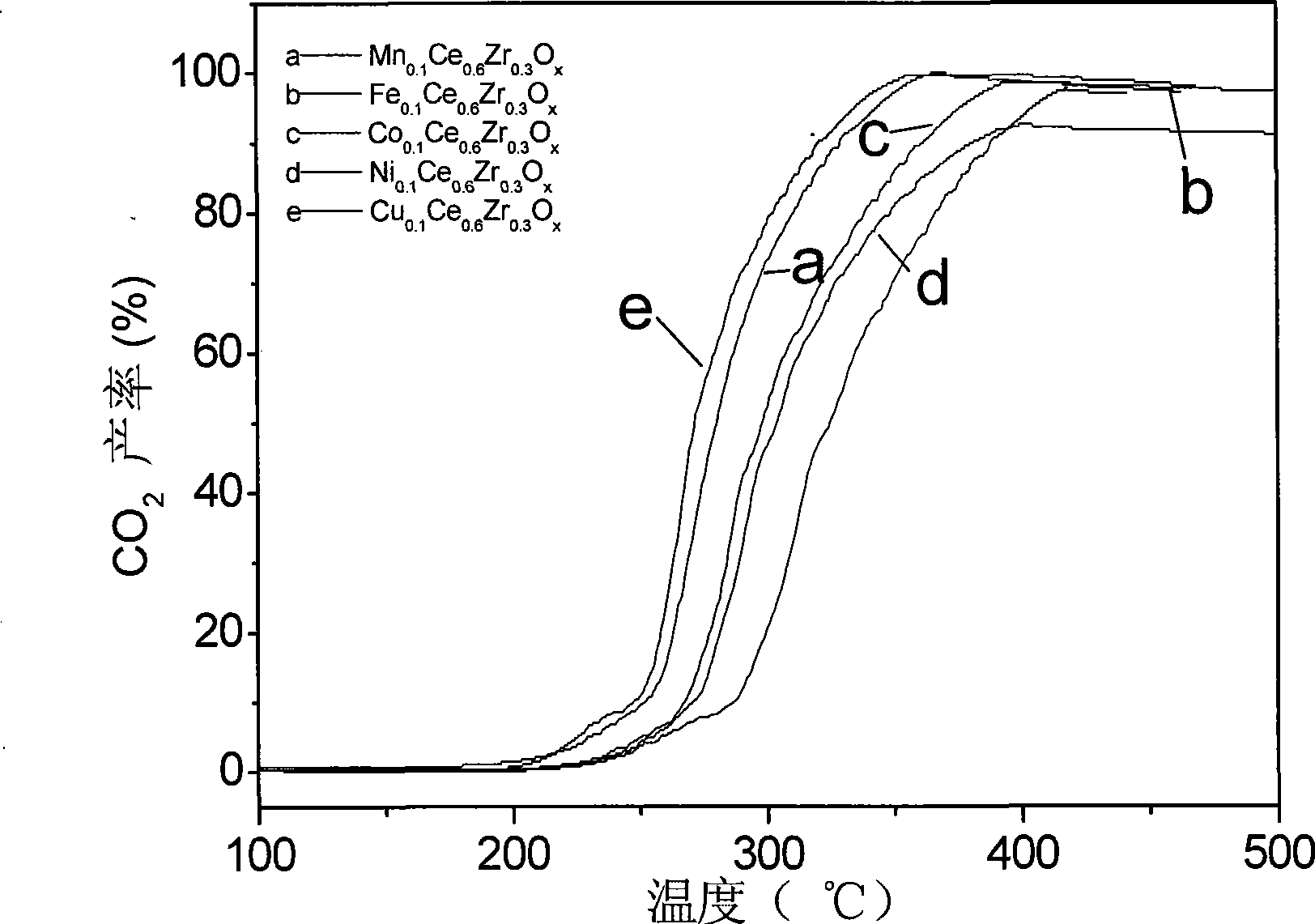

[0027] The catalyst is used to test the catalytic activity of simulated ethanol gasoline vehicle exhaust: a fixed-bed reactor is used, and 0.25 g of the catalyst is installed in a quartz tube reactor with a diameter of 12 mm. Air brings ethanol into the reaction system with a space velocity of 30000h -1 , using temperature programming (10°C / min), using infrared detection of CO in the product 2 concentration. Catalytic evaluation results such as figure 2 shown.

Embodiment 2

[0029] Weigh Ce(Ac) 3 5H 2 O 11.6312g, Zr(Ac) 4 4.4748g, Fe(Ac) 3 4.04g to make 200ml solution, weigh 65.016g citric acid to make 1548ml solution, mix well, add 30ml ethylene glycol, stir at room temperature for 30min, heat in 80℃ water bath for 12h, dry the wet gel at 100℃ for 8 hours, grind, Calcined at 500°C for 5 hours to obtain CeO 2 —ZrO 2 - FeOx catalyst. Catalytic evaluation results such as figure 2 shown.

Embodiment 3

[0031] Weigh Ce(NO 3 ) 3 6H 2 O 27.342g, ZrO(NO 3 ) 2 6H 2 O 8.667g, Co(NO 3 ) 2 2.91g made into 200ml solution; adding concentration is 2M NH 3 ·H 2 0, the final pH value was controlled at 10, and the stirring was continued for 30 min. Under continuous stirring, add ethylene glycol, ethylene glycol: mixed solution = 1:20, stir for 3h; then heat in a constant temperature water bath at 70-80°C for 12h, filter with suction, dry at 100°C for 8 hours, grind at 500°C Roasted for 5 hours to obtain CeO 2 —ZrO 2 - CoOx catalyst. Catalytic evaluation results such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com